Featured Maintenance Management

Everything You Need to Know About Maintenance Management

A maintenance program is a combination of people, software, and systems, all working towards keeping assets and equipment efficient and reliable.

Facility maintenance departments tailor highly customized maintenance plans (like reactive, preventive, predictive, condition-based, and many more) for various equipment and asset classes.

In the past few decades, maintenance management has come a long way from being a tedious paper-based process to completely automated processes with computerized maintenance management system software (CMMS software.)

Let's look at the importance of maintenance management in an increasingly competitive world, the latest developments in the field, and the different ways efficient maintenance management benefits your organization.

What is maintenance management?

The primary objectives of maintenance management are

- Optimizing maintenance costs,

- Improving asset life cycles, and

- Reducing unplanned equipment breakdowns.

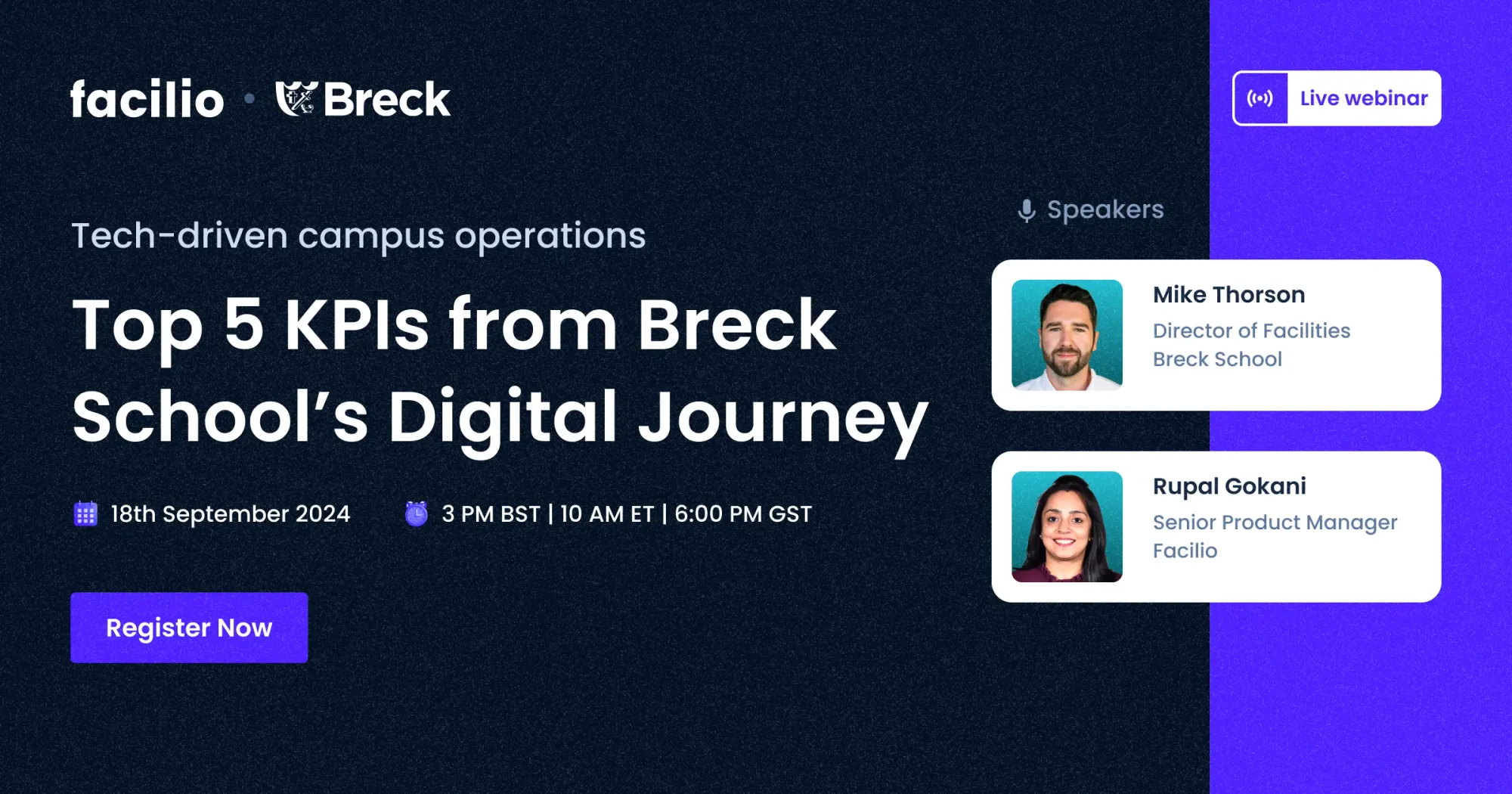

When it comes to cutting operational costs, improving occupant experience or selecting vendors- FM executives have little to no visibility to make optimisations. Understanding & tracking the right KPIs is the crucial first step to improve ops efficiency. We have carefully curated collection of the most impactful Key Performance Indicators (KPIs) that industry-leading facility managers swear by, Check out now!

Maintenance management v/s asset management

The key difference between maintenance management and asset management is:

- Enterprise asset management (EAM) is an overarching strategy that relies on data insights to maximize the efficiency of company resources to drive operational efficiency, reduce associated costs, and increase RoI.

- In contrast, maintenance management only deals with tangible assets and focuses on keeping their performance optimal, increase equipment uptime and productive hours. It helps enterprises streamline processes for Maintenance, Repair, and Operations/Overhaul (MRO) for assets and equipment.

The type of maintenance planned for each asset depends on factors like the asset's impact on operations, the bottom line, repair or replacement costs, and many more.

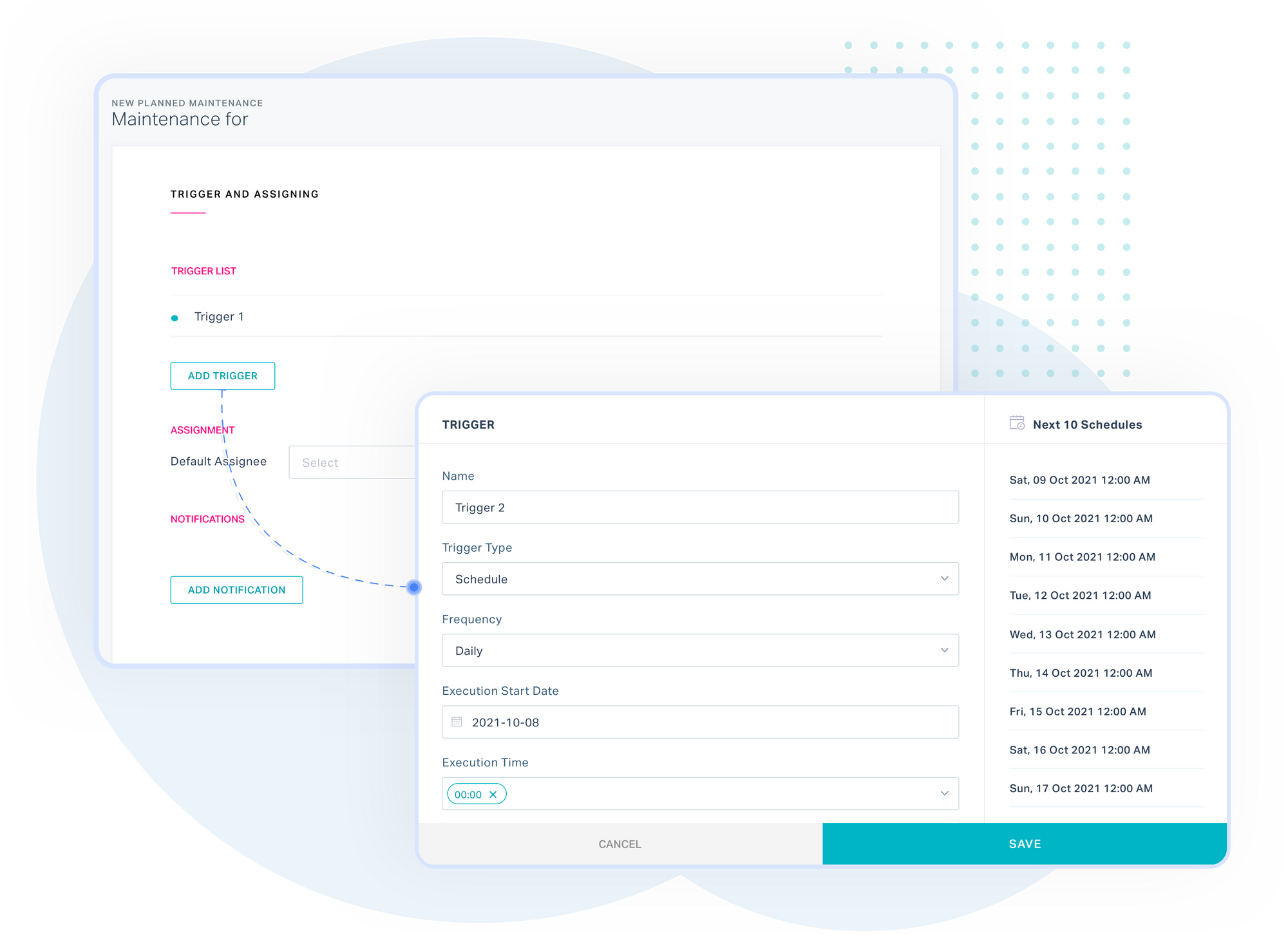

Empower your facilities with Facilio's Connected CMMS

Bring your people, processes, and systems together to transform maintenance operations forever.

Get a demoTypes of maintenance management

Businesses can utilize one of these four common maintenance management methods, either separately or in conjunction, to build an efficient and cost-effective maintenance strategy:

- Reactive maintenance (also known as corrective or breakdown maintenance)

- Preventive maintenance (also called planned preventive maintenance or preventative maintenance)

- Predictive maintenance

- Reliability-centered maintenance

Reactive maintenance (RM)

Reactive maintenance is performed as a response after an asset has failed. RM is typically aimed at low-priority equipment, which does not impact the company's production or revenue.

For example, RM is appropriate for a forklift with hydraulic problems causing forks to fail. In this case, replacing the leaking cylinder and the defective parts is less expensive than constantly monitoring the vehicle.

Understanding which assets can benefit from preventive or predictive maintenance and which RM might be more appropriate for maintenance planning is crucial.

Preventative maintenance (PM)

Preventative maintenance involves scheduling regular and routine repairs to prevent unplanned maintenance and equipment downtimes. It targets high-priority equipment that significantly impacts business operations and high repair costs.

To illustrate, planned preventive maintenance programs are recommended for tasks like a regular oil change for proper lubrication in a utility vehicle. Without an oil change, the vehicle is liable to engine damage, which can be detrimental for organizations relying on transport.

PM maintenance schedules record the original equipment manufacturer's (OEM) recommendations on the number of operational hours after which the vehicle will need an oil change.

Once you know the average asset usage for a day/month/quarter, you can calculate exactly when the following oil change is due.

Suggested read:

Predictive maintenance (PdM)

Predictive maintenance uses Internet of Things (IoT) devices and predictive analytics software to assess the real-time condition of equipment and detect signs of anomalies or deterioration that could lead to failures as predetermined in the software.

Unlike preventive maintenance, PdM uses a condition-based maintenance approach with oil analysis to suggest an oil change based on real-time vehicle performance and not solely on time elapsed since the last change.

This way, oil is changed only when the vehicle really needs it, eliminating what could be unnecessary maintenance tasks and facilitating better resource allocation and inventory management.

Asset and energy-intensive industries like oil, gas, electricity, and manufacturing are early adopters of PdM technologies as their applications can help them improve asset performance and workplace safety and energy consumption optimization by huge margins.

However, despite a higher initial investment, PdM has applications for most enterprises with complex asset and real estate portfolios.

Reliability-centered maintenance (RCM)

Reliability-centered maintenance aims to define failure modes and over time, improve the reliability and safety of the equipment.

For instance, say a conveyor belt provides an output of 500 boxes every 2 hours before it breaks down. Using this input, you can schedule maintenance work after every 450 boxes to enhance performance and save time.

While RCM can assist in reducing equipment downtimes and minimizing overhauls, it is a continuous process with high initial costs.

Suggested read:

Benefits of maintenance management

According to Finances Online, an estimated 34% of unscheduled equipment downtime occurs due to aging equipment. Mechanical failure is the next prevalent reason, contributing to about 20% of the cases.

Let's look at some common benefits of having a well-oiled asset maintenance management system.

Improved employee and asset productivity

In industries like manufacturing or retail, unexpected equipment failures threaten employee/occupant/facility safety, adding to a direct negative impact on the bottom line due to operational disruptions.

In the case of office spaces, improper maintenance results in insufficient lighting, uncomfortable heating, ventilation, and air conditioning (HVAC), and multiple electrical and fire hazards that disturb operations and keep employees from being as productive as they could be.

A maintenance management system helps identify faults and fix them before they break down, ensuring every human and machine in your facility is safe, healthy, and productive.

Lower operational costs

Emergency maintenance activities incur high costs, especially if you require a spare part for your equipment in a run-to-failure maintenance scenario.

If it's not readily available in your inventory, the cost of shipping a spare part with fast deliveries is higher than that of standard deliveries. Also, operations are disrupted till the faulty part is replaced, inviting sizable losses for businesses.

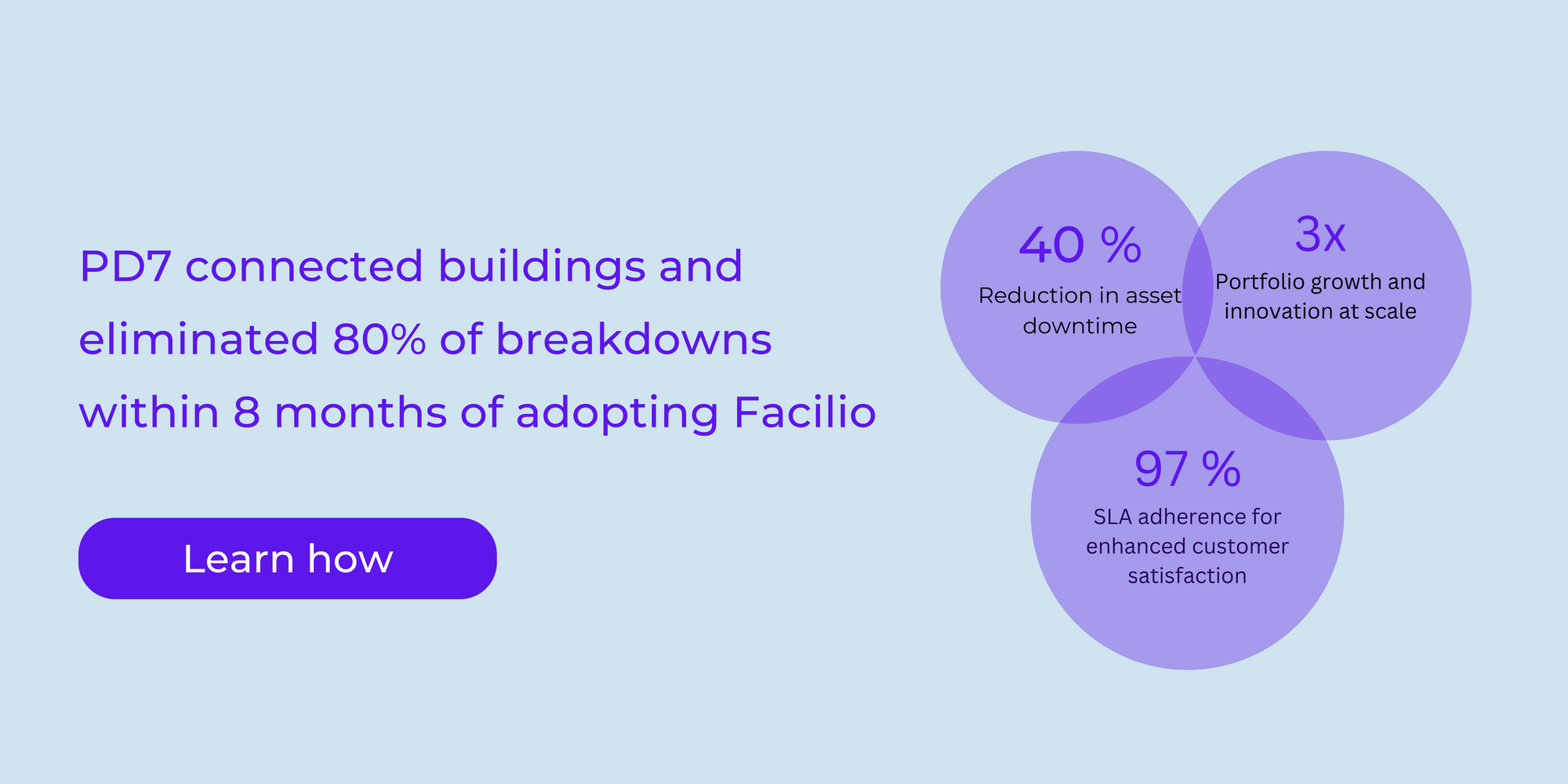

Regular maintenance maximizes asset lifetimes by keeping them running the way manufacturers intended, reducing the chance of unexpected failures and costly downtimes.

Improved asset life cycles

Facility managers (FM) and O&M teams rely on maintenance metrics and KPIs like mean-time between failure (MTBF), mean-time to repair (MTR), and Remaining Useful Life (RUL) to track changes in the safety and performance of tangible assets over time.

These are usually tracked and computed using CMMS software, with the objective is to ensure that every asset delivers its desired function and lives out its lifespan with minimal operational costs.

Insights into maintenance trends

Data-driven O&M decisions can help improve the overall efficiency of an organization. By assessing maintenance management records, you can understand issues plaguing a specific asset and take steps to avoid them.

Additionally, if an asset is less productive than expected, you can replace it instead of pouring high costs into maintenance.

Further, real-time insights reveal the effectiveness of your maintenance program and help apply learnings from each asset class to others of its kind across facilities to develop a high-performing asset portfolio.

Suggested read:

Maintenance management examples by Industry

Maintenance management is a primary need for businesses that own many physical assets.

However, in a post-COVID world with increasing safety, health, and energy regulations, it is essential for any commercial real estate property aiming to boost operational efficiency and reduce associated maintenance costs.

Manufacturing

Manufacturing plants rely on predictive maintenance to keep the facility running at peak productivity by determining failure modes, what exactly is failing, and when it will fail.

This helps maintenance teams line up inventory and technicians for essential maintenance tasks well before the predicted breakdown without ever shutting the equipment down.

Construction

Construction companies rely on a mix of preventative and predictive maintenance to forecast problems accurately and maintain budget compliance.

Additionally, routine maintenance allows them to detect defects in equipment like cordless grills and concrete mixers and schedule repairs/replacements promptly.

Office buildings

In the case of hybrid teams that work from office facilities sporadically, it becomes essential to optimize the use of HVAC systems depending on data from occupancy sensors in real time.

This keeps your HVAC systems running smoothly and only when necessary without compromising employee comfort and health. In addition, they are shut down for maintenance activities after hours to ensure the best occupant experience.

Maintenance costs amount to a large share of operational expenditure and a missed cost-saving opportunity for businesses.

What is maintenance management software?

It helps automate asset tracking, effective maintenance scheduling, work order management, and much more from one platform. In addition, it provides a convenient way for the maintenance technicians, vendors, and in-office teams to collaborate and move maintenance tasks without bottlenecks.

However, the sea of on-premise and cloud-based CMMS providers in the market may leave you spoilt for choice. So, which provider offers the best value for your organization?

Want to learn more about CMMS software?

Read the history of CMMS, it's evolution, common types, features, benefits, and more in this article:

FAQs

What does a CMMS software do?

Think of CMMS software as your maintenance control center.

It helps you keep track of everything related to maintenance - from work orders and schedules to inventory and assets.

By automating tasks and providing a centralized platform, CMMS makes your maintenance processes more efficient and effective, freeing up your time to focus on other important things.

What are the different types of CMMS and which one is best for your organization?

CMMS software come with different features and capabilities to meet your requirements and budgets:

- Cloud-based CMMS: You can access a cloud-based CMMS from anywhere with an internet connection. So, it's perfect if you have multiple locations or a mobile workforce.

- On-Premise CMMS: This type of software is installed on your own server and can only be accessed from within your network. It's a good choice if you have strict security requirements or a lot of data.

- Mobile CMMS: It is made for maintenance workers who are always on the move. It gives them access to your work orders, inventory, and asset information from a mobile device.

- Enterprise CMMS: This is for large enterprises with complex maintenance operations. It comes with advanced features like asset management, inventory control, and predictive maintenance.

- Basic CMMS: This type is for smaller organizations with simple maintenance operations. It has the basic features you need, like work order management and preventive maintenance scheduling.

What are the advantages of using CMMS software?

Here is a list of the most common advantages of using a CMMS software:

- Increased efficiency through automation and centralization of maintenance operations

- Improved asset performance through tracking and informed decision making

- Better preventive maintenance through scheduling and tracking tasks

- Accurate inventory management with real-time tracking and reduced stock shortages

- Better decision making with access to detailed maintenance and asset performance data

- Increased transparency through visibility into maintenance activities and data

- Reduced maintenance costs through increased efficiency, reduced downtime, and extended asset lifespan.

What are the key features CMMS software should offer?

Here's a concise list of key features that every CMMS software should offer:

- Work order management

- Asset management

- Preventive maintenance scheduling

- Inventory management

- Reporting and analytics

- Mobile access

What is the average cost of CMMS software?

The cost of a CMMS software varies greatly, ranging from a few hundred dollars to tens of thousands of dollars a year.

Factors like the number of assets being managed, the complexity of maintenance operations, and the number of users can affect the price.

Different pricing models, such as per-user licensing, usage-based pricing, or subscription-based pricing offer more flexibility and opportunities to scale as your needs evolve. It's important to consider all of these factors when evaluating the cost of a CMMS software.

What is the difference between ERP and CMMS?

ERP is a comprehensive system that manages core business processes such as finance, HR, procurement, and supply chain. It provides an integrated view of an organization and helps with decision making.

CMMS, on the other hand, is specialized software that only focuses on maintenance operations. It helps manage work orders, track assets, schedule preventive maintenance, manage inventory, and generate maintenance reports.

Both systems can complement each other, but ERP is broader while CMMS is more specialized.

How to evaluate CMMS software for your business?

The problem with most legacy CMMS software is their inability to connect with other tools, systems, and software to provide a truly unified platform for operations and maintenance processes.

Further, the data barrier problem, common with building management systems (BMS), poses severe problems to maintenance departments that manage large asset and building portfolios.

Enterprises of the day, with complex and ever-evolving operational needs, require a new kind of easy-to-use and connected CMMS that enables interoperability with their existing systems.

Your chosen CMMS software should enable you to:

- Plan preventive maintenance backed by real-time data

- Enable predictive maintenance for critical assets

- Easily integrate with other building management systems and software

- Automate work order generation

- Manage shared resource allocation

- Get portfolio-wide reliable compliance checks and notifications

- Benchmark assets and technology for informed purchases

- Deliver responsive and personalized tenant services

Read also: Tips to evaluate CMMS software intuitively from Investa, one of Australia's largest commercial real estate companies

This is by no means an exhaustive list, but here's a comprehensive CMMS evaluation guide you can access for free!

With an integrated CMMS system like Facilio, you get all of this and more!

Facilio sits as a cloud-supervisory platform on top of your existing site-supervisory building management systems, eliminating the need for costly new implementations and the problem of data silos forever!

Our product experts have built custom solutions for varied industries and use cases including airlines, commercial real estate, retail, and many more!

Ready to transform maintenance operations for your organization?

Get in touch with our product experts.