Predictive maintenance (PdM) uses condition monitoring tools and machine learning (ML) algorithms to predict potential failures, faults, and deterioration for assets and equipment.

Have you ever heard engineers say, "that doesn't sound right; something's broken," based on how a piece of equipment sounds?

The first time an engineer said that was the first instance of "anticipating a fault based on current operating parameters of that equipment before it breaks down" or predictive analysis.

Predictive maintenance is not a new concept. However, technological advancements have enabled various applications for predictive maintenance across several industries and use cases.

So, what exactly does predictive maintenance mean, and why is it important? Let us find out.

What is predictive maintenance? (PdM)

Predictive maintenance (PdM) uses condition monitoring tools and machine learning (ML) algorithms to predict potential failures, faults, and deterioration for assets and equipment.

Using historical asset performance and maintenance histories and predefined failure modes, PdM estimates the time of equipment failure, what exactly is failing, and recommendations to fix it.

This way, organizations are aware of potential problems and can line up resources to fix them just before equipment fails.

The objective of predictive maintenance, as with any other maintenance management strategy, is to reduce maintenance costs, eliminate unplanned downtime, and extend asset life cycles.

What is Predictive Maintenance? - A Quick Explainer

What’s the difference between predictive maintenance and preventive maintenance?

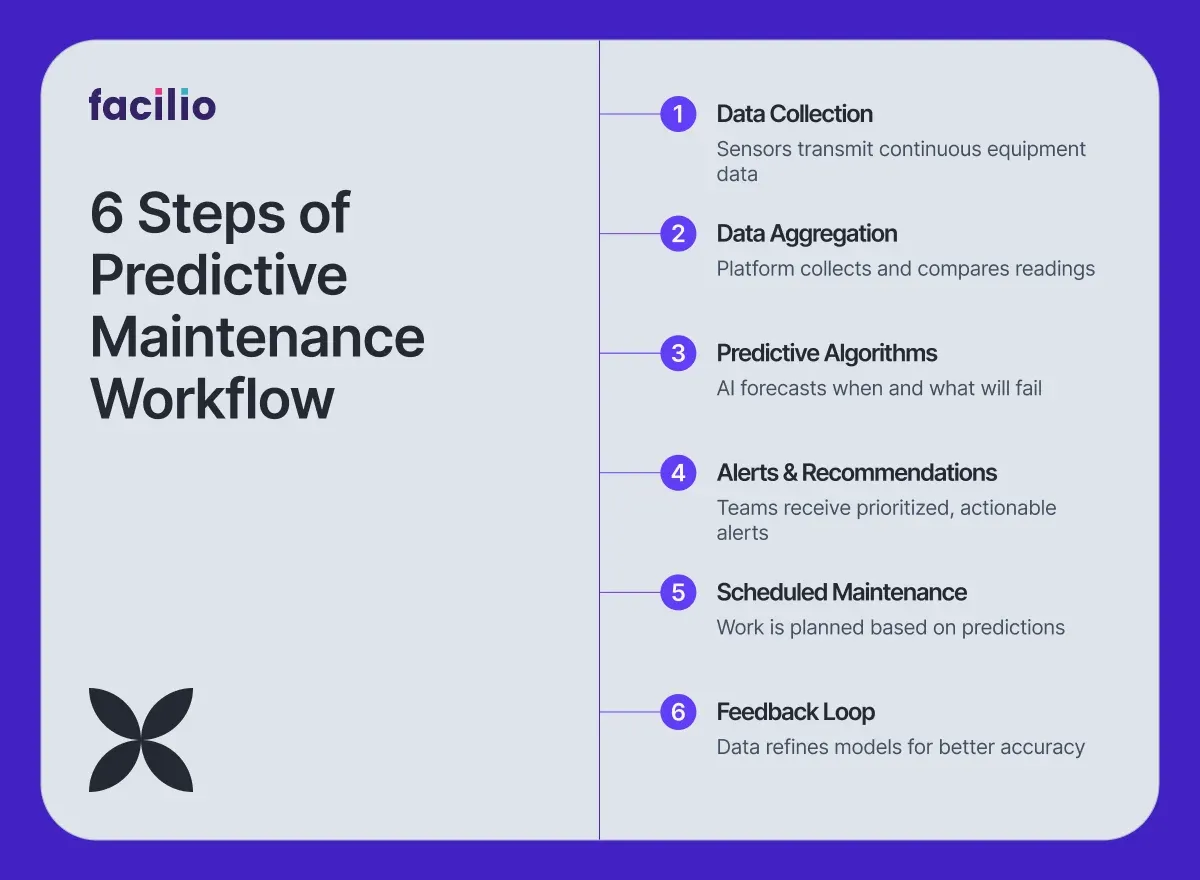

How does predictive maintenance work?

Predictive maintenance leverages combinations of condition-monitoring devices, hardware, and software to predict failures effectively and plan maintenance tasks before breakdown.

For instance, say the manufacturing guidelines recommend an oil change for your chiller after every 3000 operational hours.

As a preventive maintenance measure, a professional will dutifully change the oil on reaching 3000 operational hours–whether or not the oil change is actually necessary.

On the contrary, PdM uses Internet of Things (IoT), machine learning, and big data analytics to continually or periodically monitor equipment conditions to determine if and when an oil change is necessary.

Essentially, PdM uses real-time operating conditions data from the chiller to determine that an oil change is not necessary after 3000 hours but 5000 hours.

Further, it gives you a heads up when you have 500 miles left to go so you can line up resources and personnel for the upcoming change.

And voila, you just saved time and costs on unnecessary maintenance and also kept the chiller performing at its peak!

Key components of predictive maintenance

Here are aspects integral to an effective predictive maintenance system:

1. IoT framework for condition-monitoring

IoT devices and sensors are instrumental in predictive maintenance, facilitating the connection between physical assets and the digital world. According to a McKinsey report, using IoT sensors in facilities can reduce maintenance costs by up to 25% and equipment downtime by 70%, improve productivity by 25%, and extend asset lifetime by several years.

While sensors gather real-time insights on various equipment metrics such as vibration, temperature, pressure, and acoustics, IoT devices collect this data and transmit it to a centralized system for advanced analysis.

This constant stream of data supports condition monitoring by continuously assessing equipment health and enabling timely maintenance decisions before costly breakdowns occur.

2. Cloud infrastructure and data storage

Cloud platforms offer the necessary computational power and storage capacity for analyzing large volumes of data generated by sensors and IoT devices. They ensure scalability, enabling the PdM infrastructure to expand with the addition of more sensors or equipment.

3. Human-Machine Interface (HMI)

These are user interfaces that allow maintenance personnel to interact with the PdM system. They display data visualizations, alerts, and maintenance recommendations in an easily comprehensible format. HMIs are crucial for ensuring that insights generated by the system are effectively communicated to those responsible for maintenance.

Types of predictive maintenance

Predictive maintenance has applications in many industries, including:

Industries that involve significant worker safety risks, use sensitive and expensive equipment, incur substantial capital and operational expenses, and suffer from major business disruptions due to equipment downtime, stand to gain immensely from implementing predictive maintenance.

If you’re an asset-intensive company, explore the various types of predictive maintenance to select the most appropriate technique that helps optimize your operations:

1. Oil analysis

This involves testing the lubricants used in machinery to detect the presence of contaminants and the properties of the oil itself. By analyzing particles in the oil, technicians can identify wear and tear in the machine components.

Chemical analysis can reveal degradation of the oil, which may indicate overheating or other harmful conditions. This method is crucial for preventing mechanical failures and extending the lifespan of machinery.

For instance, in the energy sector, offshore oil platforms use predictive maintenance for critical valve and pump systems, predicting failures that could lead to environmental hazards and production losses.

2. Thermal imaging

Also known as thermography, this technique uses infrared cameras to detect and measure thermal energy emitted from equipment surfaces. Hot spots identified by these cameras can indicate areas of friction, electrical resistance, or other issues such as poor lubrication or misalignment in mechanical systems.

This technique is non-invasive and can be performed during normal operations, providing real-time monitoring without disrupting machinery function. For example, power plants use thermal imaging to track turbine blade conditions, predicting wear and tear that could lead to inefficiencies or failures, and ensuring uninterrupted power generation.

3. Acoustic analysis

This involves listening for changes in the noise or ultrasound emitted by machinery. It can detect irregular sounds like knocks, rattles, or hissing, which might indicate problems such as leaks, electrical discharges, or mechanical wear.

Technicians use specialized equipment to capture and analyze these sounds, which are often at frequencies beyond human hearing.

Predictive maintenance in urban transit systems, for example, focuses on real-time analysis of brake and track conditions, reducing the risk of accidents and improving the reliability of daily commutes.

4. Vibration analysis

This is a common predictive maintenance technique used to monitor the vibration signatures of machinery components. Each component vibrates differently, and changes in their vibration patterns can indicate issues such as imbalance, misalignment, or bearing failures.

Sensors attached to the equipment track these vibrations, and analysis software helps diagnose potential problems before they lead to a breakdown. In manufacturing, predictive maintenance algorithms analyze vibration data from CNC machines to predict bearing failures, allowing for repairs before downtime affects production lines.

5. Ultrasonic analysis

This detects high-frequency sounds produced by equipment that are inaudible to the human ear. This method is particularly useful for finding issues like gas and air leaks, electrical discharges, and poor lubrication.

Technicians use ultrasonic detectors to capture these sounds, and the data can help pinpoint the exact location of a fault within the system. Heavy machinery equipped with sensors in the construction sector monitor hydraulic systems, anticipating failures that could halt construction projects, ensuring on-time project completion.

6. Current and voltage sensors

These sensors are used for monitoring the electrical characteristics of machinery. Changes in current and voltage can indicate problems such as overloads, short circuits, or failing electrical components. Monitoring these parameters helps in maintaining electrical systems, ensuring safety, and preventing downtime due to electrical failures.

For instance, in aviation, by analyzing engine performance data in real-time, airlines can predict and address potential engine issues before they lead to flight cancellations or in-flight emergencies.

Read Also:

- Wake up before break down: How to proactively manage facilities

- A Quick Guide to Avoid Getting Pencil Whipped!

Why is predictive maintenance important?

PdM collects a wealth of data that provides insight into important questions like:

- Which assets are at the highest risk of failure?

- What is the remaining useful life (RUL) of an asset?

- What is the likely root cause of a particular fault?

- What is the probability of an asset failing within a specific period?

- What necessary maintenance should be performed to resolve the problem effectively?

These data points help organizations strategically plan resource utilization to achieve maximum uptime and productivity across portfolios.

The screenshot shows a detailed report for faults in a Fresh Air Handling Unit (FAHU), which was detected to be over-cooling.

Using Fault Detection & Diagnostics (FDD), the CMMS charts supply air temperature over a period of time, detects possible causes, and makes recommendations for fixing the over-cooling issue.

This way, PdM reduces instances of emergency repairs for unexpected equipment breakdowns, which are inherently more dangerous for maintenance personnel safety.

Case study: Learn how PD7 eliminated 80% of breakdowns with Facilio

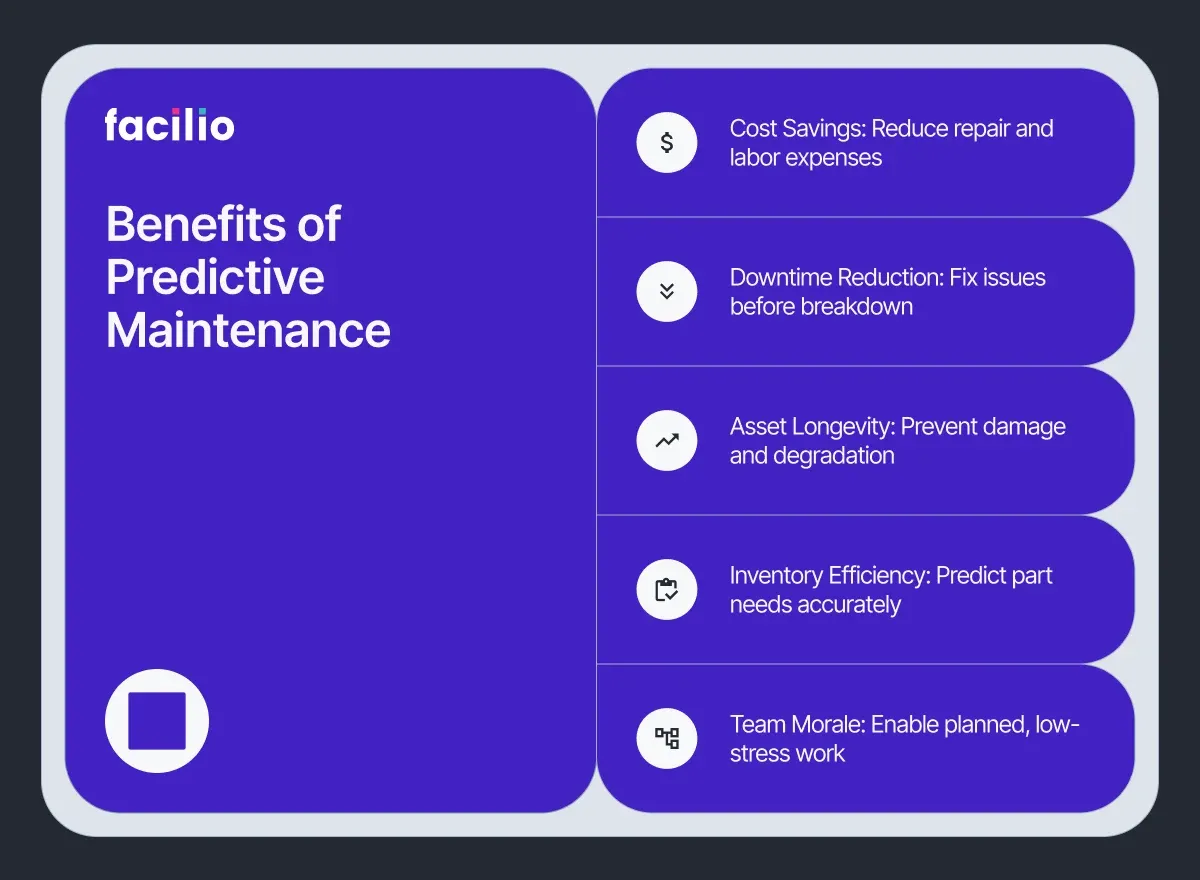

Benefits of predictive maintenance

The facility manager of a 29-storey office building said their company saved $16,742 in operating costs and another $32,300 in repair costs annually by deploying PdM for their heating, ventilation, and air conditioning systems (HVAC) alone!

Impressive, isn’t it?

Early adopters of predictive maintenance software have realized cost savings much more significant than their initial investments in more ways than one, as in the predictive maintenance example above.

Some common benefits of predictive maintenance programs include:

- Improved asset reliability with real-time condition tracking

- Reduced maintenance waste by scheduling only the necessary tasks

- Efficient inventory of spare parts to reduce mean time to repair (MTTR)

- Perform maintenance on machines and equipment while they are operating to avoid disruptions

- Improved workplace safety for everybody

Studies by the U.S. Department of Energy revealed that PdM is highly cost-effective in the long run, saving roughly 8%- 12% over preventive maintenance and up to 40% over reactive maintenance.

However, the use of PdM isn’t widespread just yet.

This is because it involves substantial upfront costs for installing condition-monitoring IoT sensors, developing predictive algorithms, and connecting them with computerized maintenance management software (CMMS) or specialized predictive maintenance software.

Related Read: Best CMMS Software

With wireless technology bringing implementation costs down, more and more businesses will harness predictive analytics in the future. Learn more on Predictive Analytics in Facility Maintenance

How to implement predictive maintenance with a CMMS software

CMMS provides the most comprehensive and easily accessible source of historical information to get started with predictive maintenance.

It automatically creates and schedules maintenance work orders when sensors detect an asset operating outside its normal, predefined parameters.

These warnings prompt the maintenance team to take preventive measures before the equipment or asset breaks down.

CMMS facilitates the interpretation of data and serves as a central organizational tool. Further, it leverages Machine Learning to:

- Build “normal” and expected event models

- Detect component problems in real-time and alert maintenance teams

- Predict component life and prioritize component replacement using predictive algorithms

- Optimize the frequency of scheduled maintenance activities and spare parts usage

Read also: How a CMMS Helps Boost Your Property Operations

Steps to implement a predictive maintenance program

☑️ Target critical equipment with high maintenance costs as they’re the best candidates for showing maximum ROI from PdM programs.

☑️ Collect historical data for chosen assets from your CMMS and other maintenance records (both digital and paper-based).

☑️ Perform Failure Mode and Effects Analysis (FMEA) to define possible failure modes for each asset.

☑️ Deploy IoT sensors and condition-monitoring techniques to collect data on the expected failure modes.

☑️ Develop predictive models using historical and sensor-derived data to anticipate future asset conditions.

☑️ Initiate a pilot with select assets to validate your PdM program based on outcomes such as improvements in asset reliability and reductions in maintenance frequency and downtime.

Suggested Read: How to measure asset reliability with a bathtub curve?

Stay ahead of the curve with predictive maintenance

The key to realizing the true value and cost savings from PdM depends on your ability to analyze available data efficiently and accurately.

Around 10% (or even less) of industrial equipment ever wears out, which means most mechanical failures are avoidable and can benefit from PdM to perform optimally.

You need a platform like Facilio to connect all your disparate data sources to enable interoperability between IoT technologies and provide real-time and actionable maintenance insights.

Facilio’s connected CMMS platform leverages data from existing building automation systems (BAS) using IoT devices to provide facilities management teams actionable intelligence to fix assets before they break down

Further, it empowers you to optimize portfolio scale O&M in real-time with data-backed decisions.

Interested in learning how predictive maintenance management can benefit your business? Don’t hesitate to get in touch!

Supercharge your assets with predictive analytics

Frequently asked questions (FAQs)

1. Can predictive maintenance be applied to different industries?

Yes, predictive maintenance is already being adopted across industries such as automotive, energy, aerospace, and manufacturing. It helps companies save money by reducing downtime, preventing equipment failures, and improving their customer service.

2. How does predictive maintenance contribute to cost reduction?

Unplanned downtime is a key negative contributor to any company’s bottom line. Predictive maintenance enables maintenance technicians and leaders to prepare, plan, and cost for a repair, taking steps such as shifting capacity to other equipment and scheduling maintenance for times with the least impact on production.

3. How can predictive maintenance be integrated into existing enterprise systems?

PdM can be integrated with existing enterprise systems such as Enterprise Resource Planning (ERP) and Asset Management systems through APIs and middleware solutions. This integration enables seamless data flow and analytics, resulting in real-time maintenance decision-making based on comprehensive insights from across your operations.

Frequently asked questions (FAQs)

1. Can predictive maintenance be applied to different industries?

Yes, predictive maintenance is already being adopted across industries such as automotive, energy, aerospace, and manufacturing. It helps companies save money by reducing downtime, preventing equipment failures, and improving their customer service.

2. How does predictive maintenance contribute to cost reduction?

Unplanned downtime is a key negative contributor to any company’s bottom line. Predictive maintenance enables maintenance technicians and leaders to prepare, plan, and cost for a repair, taking steps such as shifting capacity to other equipment and scheduling maintenance for times with the least impact on production.

3. How can predictive maintenance be integrated into existing enterprise systems?

PdM can be integrated with existing enterprise systems such as Enterprise Resource Planning (ERP) and Asset Management systems through APIs and middleware solutions. This integration enables seamless data flow and analytics, resulting in real-time maintenance decision-making based on comprehensive insights from across your operations.