Creating Actionable O and M Manuals with a Connected CMMS

An operations and maintenance (O&M) manual is a comprehensive document that provides key operational guidance and maintenance requirements for a facility or equipment. It serves as a critical resource for engineers, technicians, and facilities managers and ensures an asset’s smooth and efficient functioning.

Key takeaways

- O&M manuals often sit collecting dust, as traditional document storage systems and standalone tools fail to leverage their potential, leaving technicians unaware of their availability when resolving work orders.

- On the other hand, a CMMS (Computerized Maintenance Management System) can bridge this gap by embedding O&M instructions into work orders in the form of a interactive, digital checklists.

- A connected CMMS ensure that maintenance personnel can readily access and effectively utilize the valuable information in O&M manuals, making their guidelines not only accessible but also actionable.

The different types of O&M manuals

O&M Manuals, or Operations and Maintenance Manuals, come in various forms, each tailored to suit specific needs and sectors. Understanding these variations is crucial to ensure your facility's operational efficiency.

While the primary goal remains consistent—providing a detailed system and asset management plan—the content and structure may vary depending on the industry, region, or specific operational requirements.

a. Sector-specific manuals

Industry-specific enterprise asset management standards often dictate the format and content of O&M manuals.

For instance, healthcare facilities may require detailed protocols for medical equipment, while industrial plants might focus heavily on machinery and process systems.

In regions like the UK, compliance with regulations such as the Health and Safety Executive (HSE) guidelines is essential, while in Dubai, adherence to the Dubai Municipality Codes is critical.

b. Complex systems vs. general equipment

The complexity of the manual often correlates with the assets it covers.

Complex systems like HVAC or electrical grids necessitate comprehensive manuals with detailed schematics and troubleshooting processes. On the other hand, simpler equipment requires only brief operational guidelines.

By distinguishing these varying needs and tailoring your O&M manuals accordingly, you ensure they are not just a formality but a functional tool that enhances efficiency, compliance, and safety across operations.

Critical components of a practical O&M manual

An effective O&M manual contains detailed equipment descriptions, operational procedures, maintenance guidelines, and much more.

- Introduction: A brief overview of the facility or system and its intended audience.

- Equipment Details: Detailed asset descriptions, including specifications, model numbers, and manufacturer information.

- Maintenance Procedures: Explicit instructions for scheduled maintenance and preventative measures.

- Safety Protocols: Comprehensive documentation of all safety measures and precautions.

- Troubleshooting Guide: A practical guide for identifying and resolving common issues.

- Records and Logs: A system for logging repairs and maintenance activities, adhering to standards like BS EN 15038 in the UK and ASME (American Society of Mechanical Engineers) codes in the US and the Middle East.

- Appendices: Supplementary materials like parts lists and circuit diagrams.

If you need an in-depth exploration of the key components, we recommend checking out the Design Building’s Construction Wiki.

They provide an extensive resource for those eager to delve into the various elements found in an O&M Manual.

Best practices for creating O&M manuals

Best practices for creating and utilizing O&M manuals involve ensuring that the content is clear, concise, and regularly updated. Transitioning from standalone documents to integrated systems like a CMMS can significantly enhance the utility of O&M manuals.

- Regularly revise the manual to reflect changes: Keep your O&M manuals for equipment, procedures, and safety standards current. This will not only ensure compliance with current regulations, such as the Health and Safety at Work Act in the UK, but also help extend asset lifecycles.

- Use clear language and visual aids: Ensure the manual is comprehensible for users with diverse expertise levels. For guidance on effective documentation practices, refer to resources such as the Plain Language Action and Information Network.

- Collaborate with other stakeholders: By involving other stakeholders, you can enhance the accuracy and relevance of your maintenance manuals. Collaborative input leads to more comprehensive documentation and smoother interdepartmental workflows.

- Incorporate feedback from those who frequently use the manual: Implementing user suggestions can greatly improve the usability of your O and M manual while also enhancing technician productivity and lowering maintenance costs.

- Transition from static documents to digital manuals: Implementing interactive digital platforms like documentation hubs, standalone maintenance software, and CMMS can make O&M manuals more accessible and actionable.

Enhancing the usability of O&M manuals with technology

It's essential to consider not just the creation but also the practical application of this valuable resource. In most facility management companies, O&M manuals become mere books on a shelf—ineffective without active implementation.

Standalone maintenance software vs. connected CMMS

Traditionally, standalone software may serve as a digital repository for O&M manuals. However, this approach often limits the manual’s potential to facilitate efficient maintenance processes.

Unlike standalone management systems, a connected CMMS integrates these manuals into a comprehensive digital ecosystem, embedding them into your maintenance workflows.

Let’s consider an instance where a technician is called to service an HVAC system in a large commercial building in the UK.

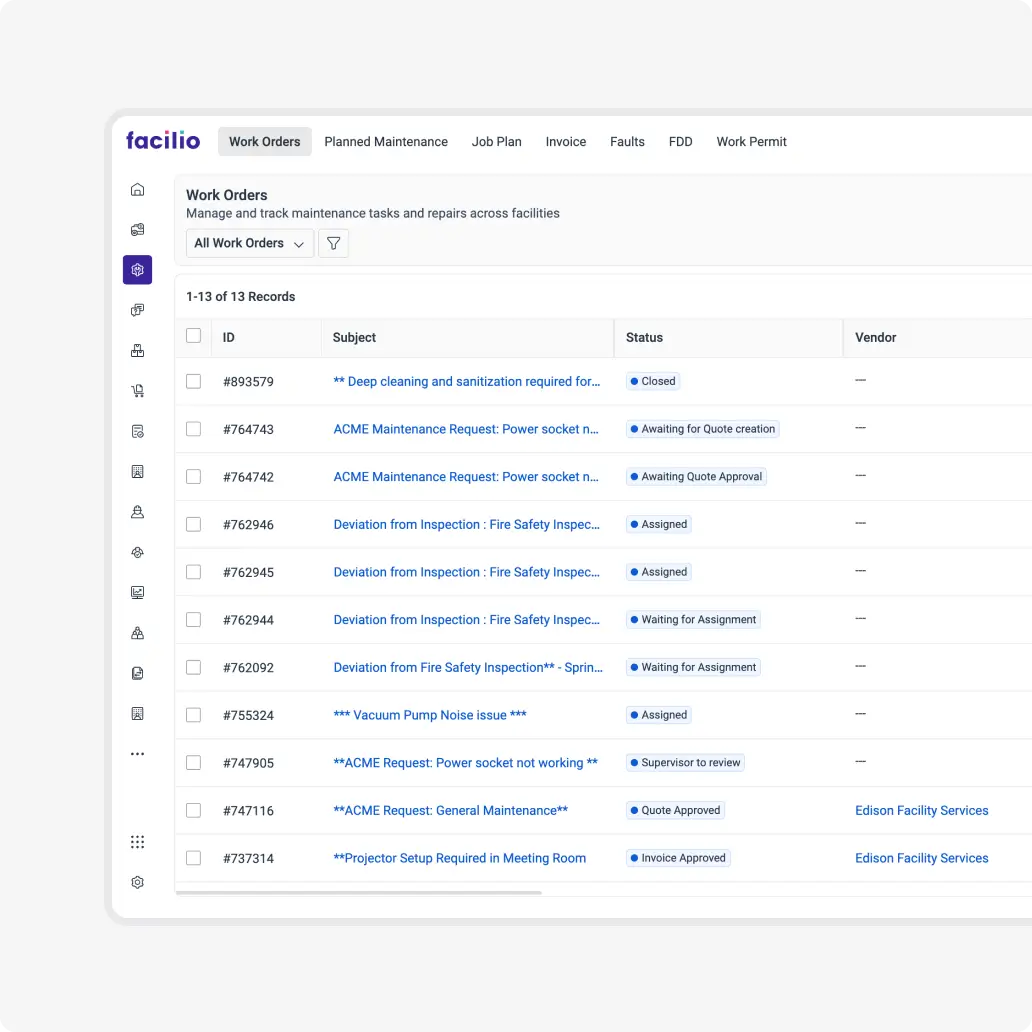

Instead of sifting through binders to find the relevant section, the CMMS delivers that information directly to the technician’s mobile device, complete with actionable checklists and service logs.

This integration ensures compliance with the UK’s building codes and standards like BS 8536, streamlining operations significantly.

And, if you're feeling the limitations of your current standalone maintenance management system, it's time to explore the advantages of a more modern, connected system. Learn more about the end of the legacy era and how Connected CMMS is the way forward.

How does a connected CMMS elevate the usability of O&M manuals?

Unlike traditional paper-based or standalone systems, the O&M manual in a CMMS leverages digital advancements to enhance usability and effectiveness.

The transition from paper to digitized format eliminates physical storage constraints and the risk of document misplacement, ensuring information is accessible whenever needed.

1. Itemizes detailed procedures

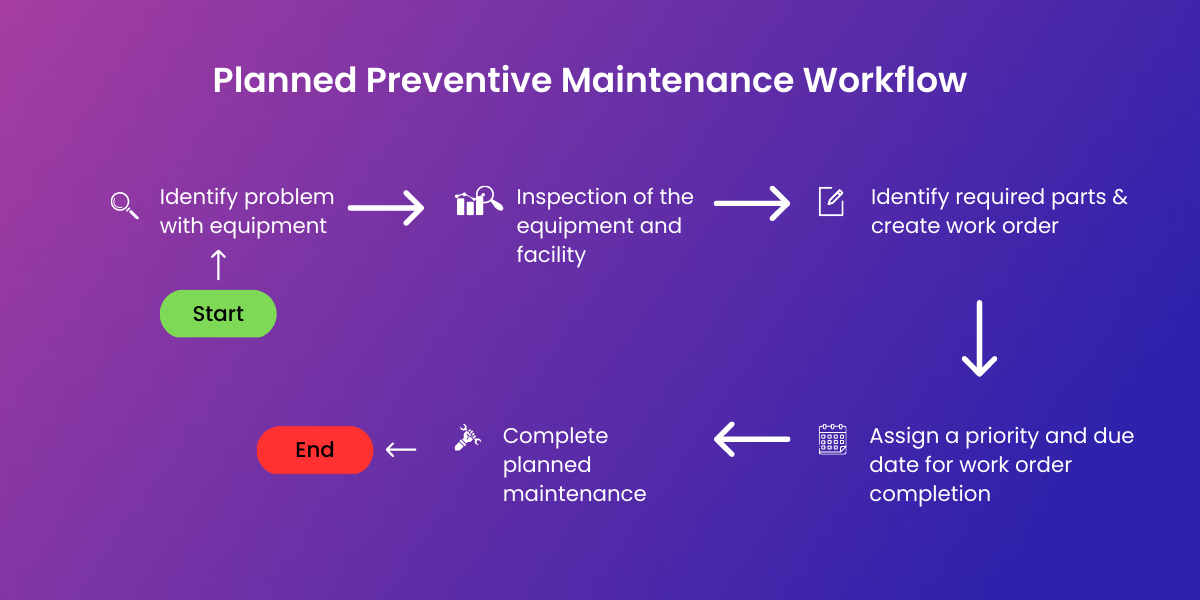

An effective O&M manual checklist within a CMMS outlines step-by-step operational and maintenance tasks with clear intervals, such as inspections, repairs, and systems tests. This digital structure allows facility managers to schedule and oversee necessary activities seamlessly.

2. Offers comprehensive preventive maintenance

By regularly detailing preventive measures, the CMMS-driven checklists enable foresight in asset maintenance, effectively mitigating failures, improving asset reliability, and enhancing machinery longevity. This proactive strategy is more economical compared to unexpected repair costs.

3. Ensures regulatory compliance

Through digital records, a well-maintained O&M manual within a CMMS proves that the facility adheres to essential safety and legal standards via routine checks and audits, enforcing asset management policies, and ensuring readiness for compliance inspections while preventing the risk of violations.

Regional Considerations: UK, Middle East, and US

O&M manuals should be tailored to meet the specific regulatory requirements and industry standards of their respective regions.

- UK: Incorporate relevant UK regulations such as the Health and Safety at Work Act 1974, the Regulatory Reform (Fire Safety) Order 2005, and the Control of Substances Hazardous to Health Regulations 2002.

- Middle East: Include specific examples like the Dubai Municipality's Green Building Regulations and the Abu Dhabi Environmental Health and Safety Management System.

- US: Reference key standards like OSHA regulations, ANSI standards, and the Americans with Disabilities Act (ADA) requirements.

4. Empowering technician efficiency

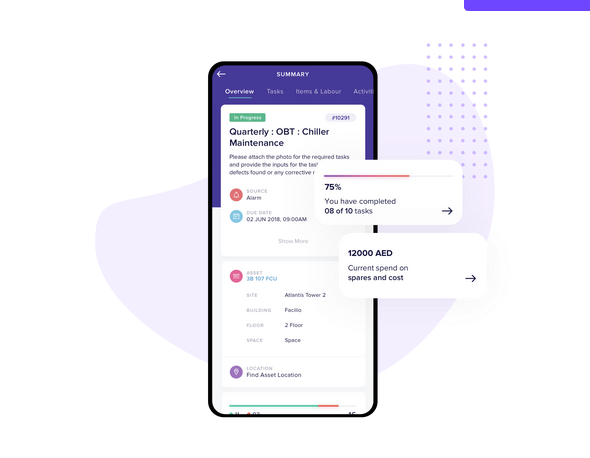

An intuitive mobile interface of a connected CMMS facilitates seamless task execution and updates, providing your mobile workforce the tools needed for efficient work completion, a significant upgrade from the cumbersome paper-based systems.

5. Offers diverse customization options

A robust checklist within a CMMS-driven O&M manual can be tailored to accommodate the unique requirements of different facilities, assets, and operational timelines, ensuring no component is overlooked. Unlike standalone systems, it is adaptable to varying operational demands.

6. Enhances operational efficiency

By integrating standard procedures into the digital checklists in the CMMS, you can ensure process consistency and be audit-ready with aggregated views of all your maintenance and asset management data.

This approach not only strengthens data integrity but also enhances the overall efficiency of your maintenance operations, providing you with reliable data insights and streamlined compliance processes.

7. Enables data collection and analysis

Data gathered from completed O&M tasks offers valuable insights into asset performance metrics, maintenance cycles, and resource allocation. Utilizing a CMMS, this data can be thoroughly analyzed to enhance operational processes further, providing far superior insights than traditional documentation can offer.

If you're ready to make an informed decision, check out our comprehensive CMMS Evaluation Guide next >>>>

Facilio: Turning O&M manuals into actionable assets

Facilio transforms O&M manuals into actionable assets by integrating them into a holistic digital framework, revolutionizing maintenance efficiency and workflows.

- Ensure compliance: Automated updates and digital records facilitate compliance with US, UK, and ME regional regulations and standards, simplifying audits and reporting processes.

- Seamless collaboration: Supports efficient communication and teamwork among maintenance crews, operations staff, and other key players, ensuring updates are shared, progress is tracked, and issues are swiftly resolved.

- Insightful analytics: Utilize data analytics to monitor key metrics such as asset downtime, reactive maintenance expenses, and compliance levels, allowing for trend analysis and strategic enhancement of maintenance operations.

- Automated processes: Enables automatic triggering of work orders based on set schedules or real-time data from physical assets, proactively reducing unplanned downtime and optimizing maintenance efforts.

- Version management: Maintains detailed records of O&M manual modifications, supporting clear communication and accountability across teams.

- Seamless work order automation: Automatically initiates work orders based on predefined schedules or real-time maintenance or breakdown data from connected asset groups.

- Drag-and-drop checklists: Facilio offers an intuitive drag-and-drop feature for effortlessly customizing checklists derived from O&M manual instructions.

- Interactive checklists: Transform O&M manual instructions into interactive checklists integrated within work orders and service requests, ensuring precise task execution.

- Instant access: Technicians have immediate access to the latest O&M manuals via mobile devices, eliminating the hindrance of bulky paper documents or outdated files.

Case study: Optimizing O&M manuals with Facilio at CIT Ltd

CIT Ltd, a leading facilities management (FM) services provider based in Saudi Arabia, recognized the pivotal role that O&M manuals play in delivering transparent and efficient operations. To enhance their utility, CIT Ltd leveraged a connected CMMS platform, transforming how these manuals were utilized.

By integrating O&M manuals into their CMMS suite, CIT Ltd achieved a centralized repository for all operational guidelines, enabling seamless access and real-time updates to maintenance procedures.

The synergy between CMMS and the O&M manuals empowered technicians to convert instructions into actionable checklists, embed them with work orders, and align them with service requests for increased accuracy and efficiency.

This digital transformation led to a drastic reduction in downtime and improved preventive maintenance scheduling. Automation within the CMMS triggered maintenance activities based on data-driven insights, harmonizing operations and significantly reducing manual errors.

Final thoughts

Creating an O&M manual is only half the battle. Its value is fully realized when seamlessly integrated into everyday operations.

By embedding O&M manuals within a connected CMMS, organizations enable real-time updates and transform sections of manuals into actionable checklists that are embedded into work orders and service requests.

This integration not only simplifies routines but also ensures that all safety protocols and maintenance checks are meticulously followed, maximizing system reliability and efficiency.

If you're ready to elevate your maintenance management and turn your O&M manuals into actionable assets, schedule a demo today and explore the transformative potential of a connected CMMS.

More from Facilio