How to Minimize Equipment Downtime in Manufacturing Facilities: A Comprehensive Guide

Every minute of idle machinery means lost production, delayed shipments, dissatisfied customers, and substantial monetary losses.

According to a recent Forbes report, the average manufacturer confronts 800 hours of equipment downtime or over $50 billion in downtime costs annually.

That's a lot of damage for something that, with the technology easily available today, can be mitigated to a large extent.

Steve Jobs said, "If you define the problem correctly, you almost have the solution," and nothing rings more true for confronting equipment downtime in manufacturing facilities or any other large commercial facilities.

Manufacturing facilities have many moving parts, all of which need to work in perfect harmony to improve production time and process efficiency. The path to minimizing downtime is anything but straightforward.

There are, however, many effective strategies you could consider to improve equipment uptime and, in turn, available production time.

1. Measure OEE to understand the impact of downtime

To comprehend the gravity of equipment downtime, manufacturers often rely on the Overall Equipment Effectiveness (OEE) metric.

OEE combines availability, performance, and quality metrics to provide a holistic view of equipment efficiency.

The formula for calculating OEE is:

For example, let's say a machine has an availability of 95%, a performance rate of 90%, and a quality rate of 98%.

The OEE would be = 0.95 × 0.90 × 0.98 = 0.8361 (or 83.61%)

This means the equipment is operating at 83.61% efficiency due to factors like downtime, speed loss, and defects.

Once you identify the OEE of your equipment, it becomes easier to compare it with benchmarks and take measures to improve its effectiveness.

2. Be proactive with maintenance, not reactive

Preventive maintenance is the key to avoiding unplanned downtime by scheduling regular maintenance activities before equipment fails. One effective approach is Condition Monitoring, which involves continuous real-time monitoring of equipment using sensors and data analytics.

For instance, vibration analysis can detect early signs of component wear, allowing maintenance teams to schedule timely repairs before critical failures occur.

3. Prioritize root cause analysis over temporary band-aids

“The most dangerous kind of waste is the waste we do not recognize,” said Shigeo Shingo, a Japanese industrial engineer who was heavily involved in the development and promotion of the Toyota Production System.

While quick fixes address immediate issues, conducting Root Cause Analysis (RCA) helps identify underlying problems to implement lasting solutions.

RCA involves techniques like the "5 Whys" to dig deeper into the root cause of a breakdown iteratively.

Resolving the core issue prevents recurrence and reduces the chances of equipment downtime significantly.

4. Leverage the power of AI and machine learning for predictive maintenance

Predictive maintenance harnesses the power of Artificial Intelligence (AI) and Machine Learning (ML) to forecast equipment failures by understanding equipment performance and peak productivity over a period of time.

Advanced algorithms analyze historical data, equipment behavior, and environmental factors to predict potential breakdowns.

With predictive insights, you can schedule maintenance proactively and avoid production stoppages with efficient utilization of time and resources.

5. Make your critical assets more reliable with the right maintenance

Reliability-centered maintenance (RCM) is a systematic approach that identifies critical assets and determines the most effective maintenance strategy for each.

Once you understand and categorize equipment based on criticality and impact on production, you can allocate resources more efficiently, prioritizing maintenance efforts where they matter most.

Optimize maintenance schedules to coincide with periods of low demand or planned downtime.

6. Foster a culture of continuous improvement

Implementing total productive maintenance (TPM) is a holistic approach that involves all employees in maintaining equipment.

This includes operators conducting routine inspections, cleaning, and minor adjustments. Engaging the entire workforce in TPM fosters a culture of responsibility and ensures the early detection of anomalies.

7. Keep an eye on uptime and failure metrics

Two vital metrics for assessing equipment reliability are Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR).

MTBF measures the average time a machine operates between failures, while MTTR quantifies the average time it takes to repair the equipment.

Lowering MTTR and increasing MTBF is central to reducing downtime.

8. Training and upskilling maintenance teams

Investing in continuous training and upskilling for maintenance teams pays off in many ways.

Well-trained personnel can quickly diagnose issues, perform complex repairs, and adopt new technologies, thereby maximizing equipment reliability and uptime.

9. Utilize remote monitoring and assistance

“We have become a white-collar workforce, and automation has become a necessity.”—Randy Breaux, President, Motion Industries.

Incorporating remote monitoring and assistance technologies empowers maintenance teams to troubleshoot equipment issues from a distance.

This ability to diagnose problems remotely leads to faster response times, reducing downtime and minimizing resource costs.

10. Optimize spare parts management

Maintaining a well-organized inventory of spare parts is crucial for reducing equipment downtime. Keep track of essential spare parts, and ensure they are readily available when needed.

Implement a proper inventory management system, and consider collaborating with equipment manufacturers to get timely access to spare parts.

For critical processes, redundancy and standby equipment can be a game-changer.

Having backup machines or components readily available ensures that production continues seamlessly, even in the event of primary equipment failure.

11. Monitor environmental conditions

Environmental factors can influence equipment performance more than you think. Monitor temperature, humidity, and other relevant conditions that may impact machinery to anticipate potential issues.

Installing environmental sensors and alarms can help you take preventive action before any major disruptions occur.

12. IoT and Industry 4.0 integration

Embracing the Internet of Things (IoT) and Industry 4.0 revolutionizes maintenance practices and enables you to optimize your equipment in real time.

Smart sensors continuously collect data on equipment performance, enabling predictive insights, remote monitoring, and real-time analysis, thus preventing unplanned downtime.

13. Incentives for downtime reduction

Motivate employees to participate in downtime reduction initiatives actively through incentive programs, which can be very powerful in fostering a TPM culture across the organization.

Rewards and recognition for teams that successfully minimize equipment downtime create a sense of ownership and encourage continuous improvement.

14. Document and analyze downtime incidents

Maintain a detailed record of downtime incidents and their associated costs. Analyze patterns and trends to optimize resource allocation, fine-tune your maintenance strategies, and identify opportunities to improve equipment performance.

Tie it all together with a CMMS

In the pursuit of reducing equipment downtime, the role of CMMS in manufacturing facilities cannot be overstated.

It serves as a centralized hub for maintenance management, enabling precision in preventive maintenance, streamlining work order management, providing data-driven insights, optimizing spare parts inventory, streamlining compliance and documentation, and facilitating real-time monitoring with IoT integration.

It empowers manufacturers to conquer downtime challenges and achieve operational excellence by harnessing the power of technology, optimizing maintenance practices, and embracing a proactive approach to minimize equipment downtime, ensuring uninterrupted production.

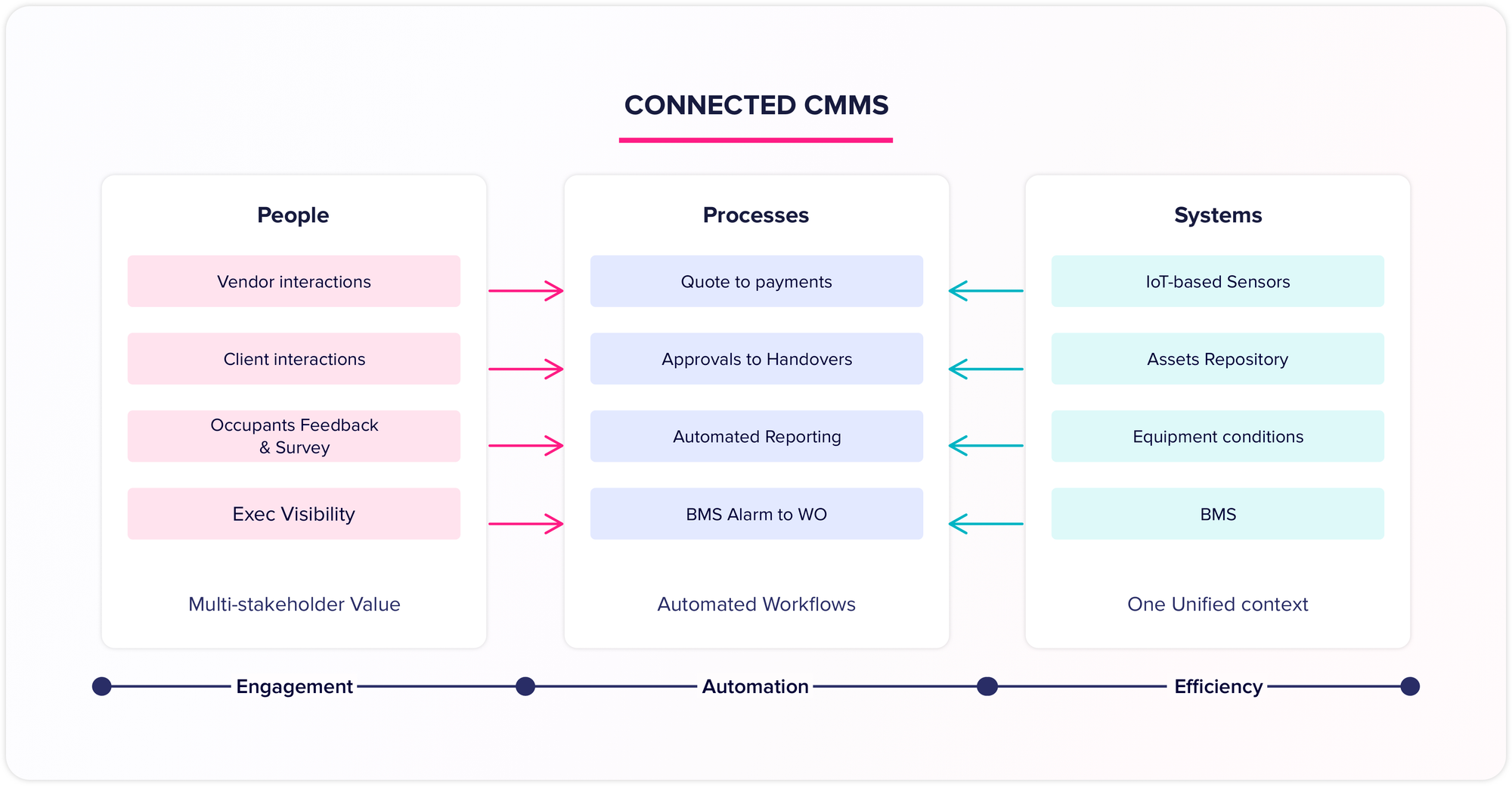

Facilio's Connected CMMS platform goes beyond just asset and maintenance management by connecting systems, people, and processes meaningfully.

It goes beyond the boundaries of most CMMS, which handle work orders and maintenance, to automate processes end-to-end, enable stakeholder engagement, and drive connected efficiency–all in one place.

As the manufacturing landscape continues to evolve, CMMS remains a cornerstone in the relentless pursuit of maximizing efficiency and minimizing downtime.

Your legacy CMMS is probably not up to the task–we'd love to show you the future of property operations technology with a Connected CMMS that unites all things O&M at the heart of it all.

More from Facilio