Articles by the Author

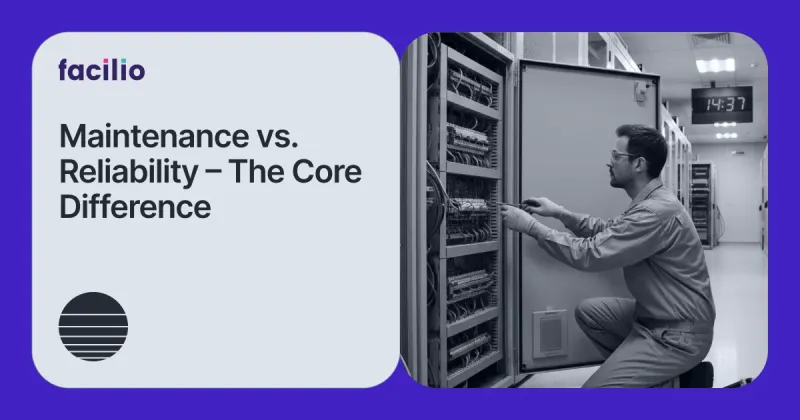

PRODUCT

Connected CMMS

Connected Buildings

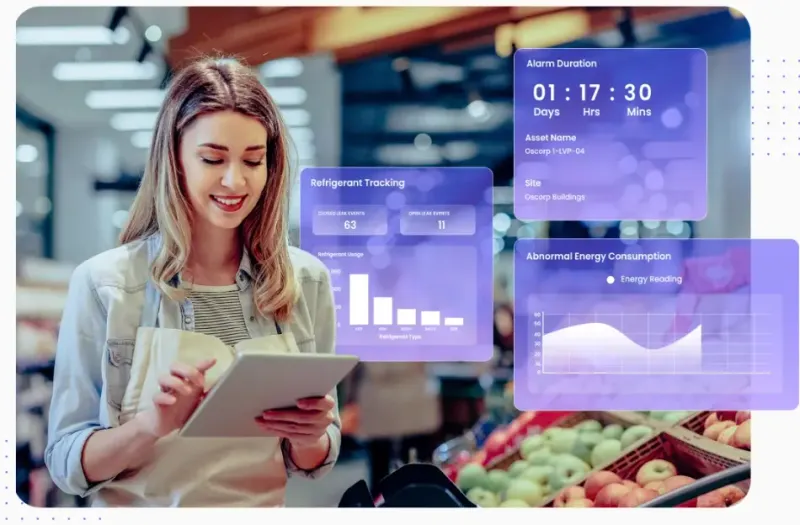

Connected Refrigeration

Connected CMMS

Unify people, processes, and systems for seamless property operations

Learn more

PLATFORM MODULES

Connected CMMS

Connected Buildings

COMMUNITY FOR FACILITY LEADERS

Game changers club

Community of O&M champions driving tech-powered transformation