Retail success isn’t just about great products and eye-catching displays.

Behind the scenes, the reliability of every store system—from lighting and HVAC to refrigeration and signage—plays a crucial role in shaping customer experience, brand reputation, and operational costs.

This is exactly where retail maintenance management comes in.

What is retail maintenance management?

Retail maintenance management is the process of planning and coordinating the tasks that keep stores safe, efficient, and customer-ready.

You might also hear it called retail store maintenance—it covers routine upkeep, seasonal checks, vendor coordination, and compliance activities like refrigeration leak management.

Now, if you’re running a single store, that might sound manageable. But for multi-site retailers, the challenge multiplies quickly.

How do you ensure every location stays consistent?

How do you prevent costly, reactive repairs from piling up?

And most importantly, how do you keep expenses in check across dozens—or even hundreds—of stores?

That’s where a structured approach makes all the difference.

See, retail maintenance today isn’t about scrambling for quick fixes when something breaks. Every retailer has to understand why it matters, what activities fall under it, and how modern technology is changing the way retailers stay ahead of these demands.

Why retail maintenance matters for your store?

A well-managed maintenance program impacts every corner of retail operations. Here’s why it’s critical:

✨ Customer experience & brand perception

- Well-lit, comfortable, and safe stores encourage longer visits and repeat business.

- Neglected facilities (flickering lights, faulty HVAC, broken signage) create a poor impression and reduce trust.

⚙️ Operational efficiency

- Prevents unplanned downtime that disrupts store operations.

- Extends asset lifespan by keeping equipment (HVAC, refrigeration, escalators, lighting) in top condition.

- Ensures smooth daily functioning without constant firefighting.

💰 Financial impact

- Reduces costly emergency repairs by emphasizing preventive maintenance.

- Lowers energy bills with optimized HVAC and refrigeration performance.

- When measured correctly, the retail CMMS ROI becomes clear—retailers see significant savings from fewer breakdowns, better vendor performance, and longer asset life.

📋 Regulatory compliance & safety

- Keeps stores aligned with health, safety, and environmental regulations.

- Critical for sectors like food retail, where refrigeration leak compliance is mandatory.

- Reduces liability risks from unsafe facilities.

🏬 Multi-site consistency

- Standardizes maintenance practices across dozens—or even hundreds—of stores.

- Improves vendor coordination and ensures SLAs are met.

- Provides portfolio-wide visibility into performance and cost drivers.

📊 Data-driven decision making

- Centralized maintenance data uncovers trends and inefficiencies.

- Helps balance reactive vs preventive work.

- Supports smarter planning for labor, vendor use, and capital expenditures.

What does retail store maintenance include?

Retail maintenance spans a vast range of activities—some visible to customers, others behind the scenes. Together, they ensure a store is safe, efficient, and customer-ready every day.

🛠️ Interior maintenance

- HVAC servicing for comfortable air quality

- Lighting inspections and replacements

- Cleaning and sanitization of floors, shelves, and restrooms

- Fire safety equipment checks

- Elevator/escalator upkeep

🏬 Exterior maintenance

- Storefront signage repair and upkeep

- Parking lot maintenance (lighting, paving, line painting)

- Landscaping and exterior cleaning

- Roof inspections and drainage system checks

- Pest control

❄️ Specialized maintenance

- Refrigeration systems (critical for supermarkets and convenience stores)

- Food safety equipment inspections

- IoT-connected devices and sensors for real-time monitoring

- Security systems (CCTV, alarms, access controls)

- Energy management systems

🔧 General upkeep

- Routine repairs (fixtures, shelving, counters)

- Waste management and recycling

- Seasonal decorations and display installations

Seasonal and preventive retail store maintenance checklist (tuned for U.S retailers)

A proactive maintenance checklist helps U.S. retailers avoid last-minute breakdowns, particularly during peak shopping seasons and extreme weather conditions. Here’s how to plan ahead:

🛍️ Peak season readiness (Black Friday, holiday sales, back-to-school)

- Service HVAC to manage heavy in-store traffic during colder months.

- Check indoor and outdoor lighting (parking lot lighting is critical for evening shoppers).

- Test POS systems, kiosks, and self-checkout stations to handle higher transaction loads.

- Refresh cleaning schedules to match extended store hours.

- Stock critical spare parts (lights, HVAC filters, POS printer rolls).

- Ensure fire systems, emergency exits, and ADA accessibility features are operational.

❄️ Winter preparation (snow-prone regions, Midwest & Northeast)

- Service heating systems and replace filters before cold snaps.

- Seal doors and windows to prevent heat loss and rising utility bills.

- Clear and salt parking lots, walkways, and loading docks for safety.

- Inspect roof drainage and gutters to avoid ice dams.

- Test snow blowers and ice-melt systems (where applicable).

- Inspect backup generators to prepare for winter power outages.

- Monitor refrigeration units closely to prevent food safety issues during temperature swings.

☀️ Summer readiness (South, West, and high-heat regions)

- Tune up air conditioning systems before heat waves.

- Clean condenser coils on refrigeration and AC units for energy efficiency.

- Test coolers/freezers to handle peak load during July 4th and Labor Day sales.

- Inspect water supply lines for leaks or pressure issues.

- Review pest control programs (rodents and insects spike in summer).

- Provide shaded or ventilated rest areas for staff during high-heat advisories.

- Check rooftop units for weatherproofing against sudden thunderstorms and hurricanes (common in the Gulf and coastal regions).

Measuring retail facility maintenance performance: What are the key KPIs to track?

You can’t improve what you don’t measure. That’s why the most effective retailers track a set of maintenance key performance indicators (KPIs) to understand costs, performance, and efficiency across their stores.

📊 Here are the KPIs that matter most:

What are the challenges plaguing retail facility maintenance?

Managing facility maintenance across retail stores is rarely straightforward. Here are some of the biggest hurdles retailers face today:

⚡ Too much reactive work

- Many stores still wait until something breaks before fixing it.

- This “firefighting” approach is costly, disruptive, and shortens asset life.

- The ideal mix? Experts recommend shifting to 60–70% preventive tasks and only 30–40% reactive.

👷 Labor shortages and skill gaps

- Qualified technicians are in short supply, making it more challenging to meet all maintenance needs.

- Even when teams are available, multi-site retailers often struggle with uneven skill levels across locations.

- Result: some issues linger longer than they should, affecting both customer comfort and safety.

🤝 Vendor sprawl and coordination issues

- Large retail chains often work with dozens of local contractors and service providers.

- Without proper oversight, it’s easy to lose track of who is responsible for what, or whether SLAs are being met.

- This leads to inconsistent service quality across locations.

💰 Cost pressures

- Maintenance budgets are tight, but unexpected breakdowns can drain resources quickly.

- Poor visibility into costs per store or per asset often makes it hard to plan or justify spending.

- Multi-site operators especially struggle with balancing cost efficiency and quality of service.

🌍 Regulatory and compliance demands

- Food retailers face strict rules around refrigeration leak detection and temperature control.

- Safety regulations (fire exits, elevators, electricals) require regular inspections and documentation.

- Non-compliance isn’t just a fine—it risks reputation and customer trust.

📉 Disconnected systems and data silos

- Many retailers still rely on spreadsheets or outdated CMMS tools.

- Without a connected system, maintenance data is fragmented across stores, vendors, and service logs.

- This makes it difficult to analyze trends, measure KPIs, or improve performance at scale.

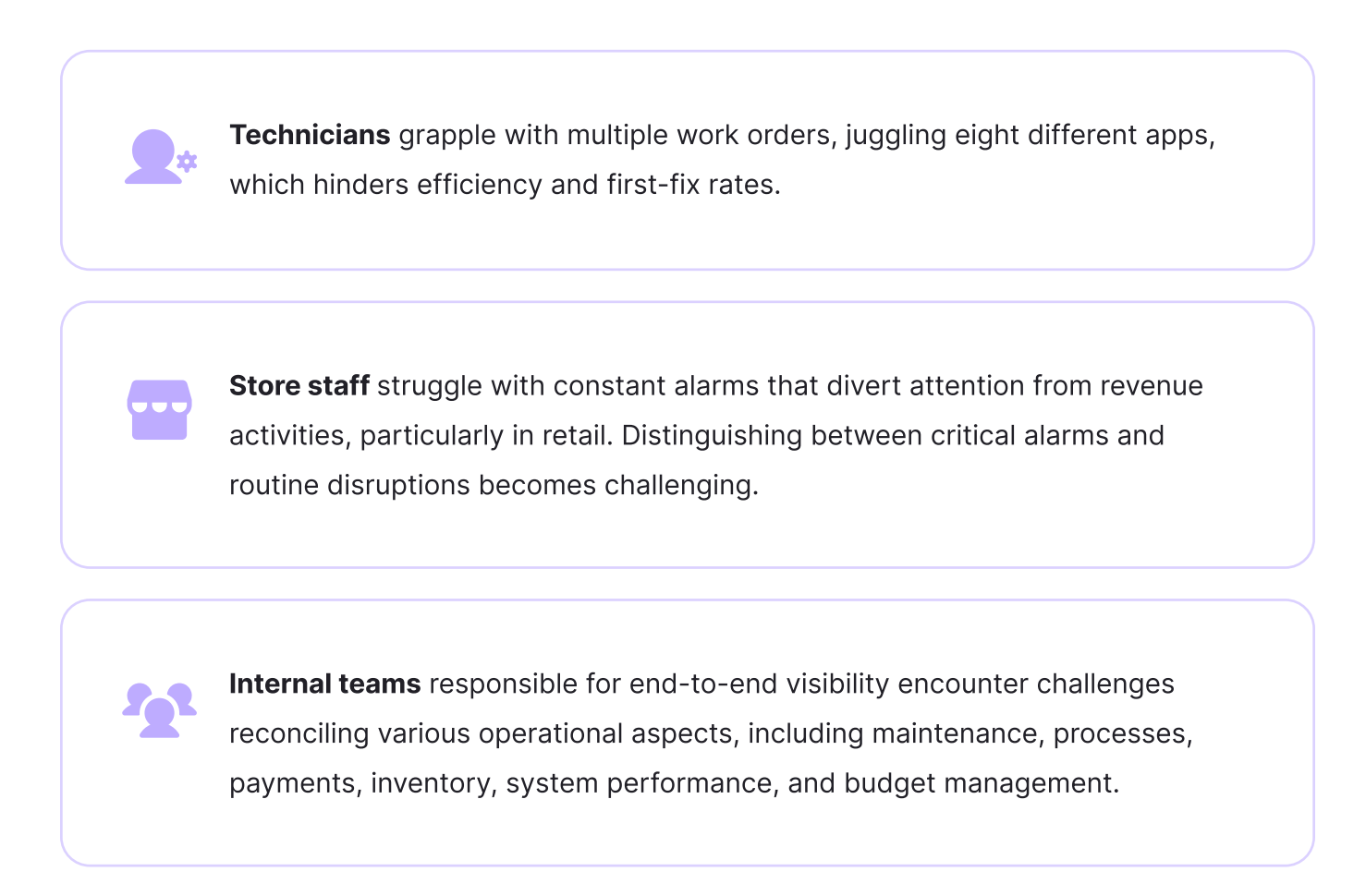

How are outdated tools holding back retail store maintenance?

Legacy systems—whether outdated CMMS tools, spreadsheets, or scattered vendor portals—may have worked when operations were smaller. But for today’s multi-site retailers, they create more problems than they solve.

Let’s look at the most common pain points and why they hold back operational efficiency.

1. Data silos and blind spots

With information split across emails, spreadsheets, and regional systems, retail teams rarely have a single source of truth.

- What you see: Duplicate asset records, missing IDs, inconsistent naming conventions.

- Impact: Leaders make decisions on outdated data, making it nearly impossible to benchmark store performance or reduce reactive work.

2. Slow ticket-to-fix cycles

When work orders are raised over phone calls or unstructured chats, important details get lost.

- What you see: Long acknowledgment times, poor prioritization, repeat visits for the same issue.

- Impact: Downtime stretches longer than it should, hurting both sales and customer satisfaction.

3. Vendor sprawl with little oversight

Retailers often rely on dozens of service providers across different regions. Without central visibility, accountability is patchy at best.

- What you see: SLA breaches discovered late, expired insurance, and inconsistent service quality.

- Impact: Higher costs and uneven customer experience across stores.

4. Compliance that’s manual and risky

From refrigeration leak logs to safety inspections, many retailers still track compliance in spreadsheets.

- What you see: Incomplete records, backfilled entries before audits, lack of traceability.

- Impact: Increased risk of fines, product spoilage, and reputational damage.

5. No portfolio-wide view

Legacy systems manage maintenance store by store, not as a connected portfolio.

- What you see: Difficulty comparing costs per store or per square foot, misaligned capex planning.

- Impact: Resources are allocated reactively rather than strategically.

6. Poor usability and adoption

Clunky UIs, lack of mobile support, and weak integrations make legacy CMMS frustrating for frontline teams.

- What you see: Field technicians skip logging updates, fall back on calls and emails.

- Impact: Leadership dashboards look fine, but reality on the ground remains chaotic.

If any of these sound familiar, your current system is likely holding you back:

More than 50% of work orders are reactive.

First-time fix rate is below 70%.

Over 20% of work orders lack an asset ID.

SLA hit rate falls below 85% for priority calls.

The way forward

Modern, connected platforms address these challenges head-on by:

- Providing a unified data model across all sites.

- Automating compliance logs for refrigeration and safety.

- Delivering real-time vendor scorecards and SLA tracking.

- Enabling integrations that turn IoT alarms into actionable work orders.

This shift isn’t about replacing tools for the sake of it—it’s about building a foundation for smarter, more consistent retail operations at scale.

Why Facilio’s purpose-built retail CMMS is the future of store maintenance

❌ Generic systems don’t cut it anymore

- Retail operations are unique: multiple sites, critical refrigeration, strict EPA rules, and nonstop customer expectations.

- Legacy tools leave you firefighting, chasing paperwork, and guessing which store needs attention first.

✅ Facilio is purpose-built for retail, and here’s how it stands apart:

- One connected platform that combines CMMS, refrigeration compliance, energy, and remote monitoring.

- Regulatory-ready workflows aligned with EPA, CARB, and GreenChill standards.

- Scalable architecture designed for multi-site portfolios, whether you operate a dozen stores or thousands.

📈 Real results in action

- Tuten Labs case: 10,000+ retail sites automated across the United States.

- Alarm noise cut through the centralized triage.

- Double-digit reduction in customer service calls.

- Faster response times with system-led prioritization.

Click here to read the full case study.

- King Kullen, a U.S. grocery chain, turned to Facilio for visibility and compliance. Instead of scrambling to assemble records before audits, they now have real-time tracking of assets, vendors, and inspections—all from a single dashboard.

These are not isolated wins.

Retailers across the United States are discovering the same truth: Facilio isn’t just another CMMS option—it’s a connected operating model for retail. It transforms scattered, reactive processes into proactive, data-driven maintenance strategies that protect margins and elevate customer experience.

👉 Ready to see how it works across your portfolio?

Request a tailored walkthrough designed for your compliance needs, vendor model, and store footprint.

Explore Facilio's Connected Retail solution for yourself, or book some time to see a personalized demo.