10 Benefits of CMMS That Make It a Must-Have in 2025

Managing facilities with outdated systems is like trying to run a marathon in shoes that are falling apart.

Legacy systems - spreadsheets, paper logs, and clunky software, create more headaches than solutions. They leave gaps in data, waste time, and rack up unplanned costs. But modern CMMS? It’s a game-changer.

By centralising all your maintenance data, automating tasks, and giving you real-time insights, it helps you stay ahead of the curve and keep things running smoothly.

Now, let's explore the key benefits of CMMS and how it drives real, tangible value for your operations.

Top 10 Benefits a CMMS Offers

Implementing a CMMS offers undeniable benefits that far exceed the initial investment.

Streamlined operations, improved efficiency, reduced downtime, enhanced collaboration, data-driven decision-making, and future growth opportunities make it a smart and rewarding choice.

Here are 10 benefits of CMMS that make it a tool of strategic importance for O&M excellence:

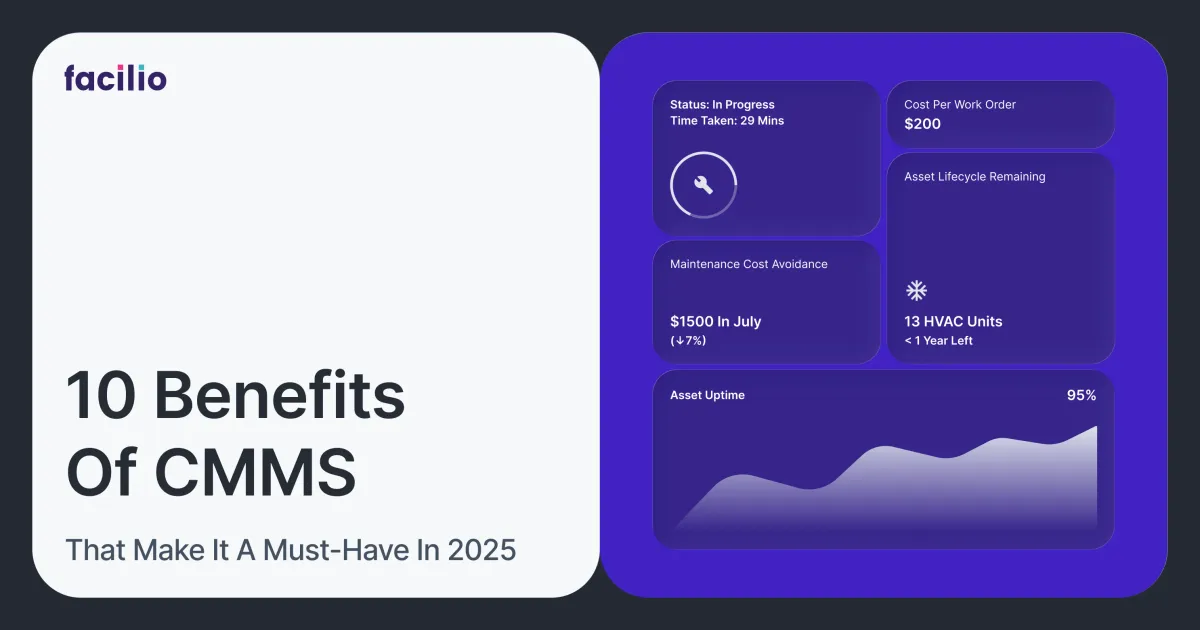

- Boosts asset uptime and reliability

When systems are always running, so is your business. Proactive servicing dramatically reduces emergency repairs and extends equipment life cycles, turning costly breakdowns into controllable, scheduled maintenance events

Automated preventive maintenance ensures equipment gets serviced before failure - not after. Stay ahead of breakdowns with condition-based alerts, SOP-attached jobs, and frequency-based PMs.

- Centralises work order management

Ditch the sticky notes! Assign, prioritise, track, and close service requests from one connected dashboard.

A single source of truth keeps operations moving. With every request, update, and closeout happening in one place, managers gain instant visibility while technicians cut down on wasted time.

- Reduces maintenance costs

Proactive care = fewer breakdowns.

Labour is used efficiently, and parts aren’t wasted.

Emergency repairs, manual scheduling, and inventory overruns bleed budgets dry. CMMS lets you move from reactive chaos to cost-optimised preventive maintenance, where every dollar is accounted for.

With 75% of facilities reporting a drop in breakdowns after switching to CMMS, your cost per repair shrinks, overtime costs fall, and you only order the inventory you need.

- Enhances compliance and audit readiness

When safety and compliance are on the line, paperwork can’t fail you. A CMMS offers an audit trail that’s not only tamper-proof but also instantly accessible when regulators come knocking.

Every inspection, checklist, and repair log is auto-recorded, perfect for audits or incident traceability.

- Improves team productivity

Maintenance teams aren’t wasting hours on back-and-forths or missing updates. Mobile access ensures everyone is in sync, whether they’re on-site or remote.

Clear communication and streamlined workflows mean technicians spend more time fixing and less time figuring out what’s next. That translates to higher team morale and more jobs done per day.

- Enables data-driven decision-making

CMMS turns every maintenance action into data. With dashboards, reports, and visual trendlines, you’re optimising maintenance.

Dashboards track trends like fault frequency, asset downtime, and labour utilisation - giving leaders the clarity to act.

Leadership thrives on visibility. With insights from your CMMS, you can spot what’s working, identify bottlenecks, and back every budget or hiring request with hard numbers.

A data-driven approach allows you to adapt and optimize your maintenance strategies for future challenges and changing business requirements.

- Smarter spare parts inventory control

Forget the last-minute scrambles. Always know what’s in stock, what’s low, and what’s obsolete.

From real-time part availability to auto-triggered reorder points, inventory management moves from reactive to optimised. Integrated CMMS inventory ensures the right parts are always available, cuts stockouts, and triggers reorders automatically.

- Vendor and contract management made easy

Managing multiple vendors and SLAs manually? That’s a time sink.

CMMS software allows you to track and evaluate the performance of your maintenance service providers. CMMS provides data-driven insights into vendor performance by recording response times, completion rates, and customer satisfaction ratings.

- Eco-friendly and energy efficient

From HVAC runtime analytics to leak detection alerts - make smarter, greener choices without guesswork.

Sustainability doesn’t start with a retrofit - it starts with visibility. CMMS tracks real-time energy consumption at the asset level, helping teams uncover inefficiencies and eliminate waste.

- Conquer maintenance backlog

Persistent backlog? Automate task assignment based on asset criticality, technician availability, and SLA urgency - eliminating ticket piles and long-lost requests.

Teams finally get to work on high-impact projects, not just today’s fires.

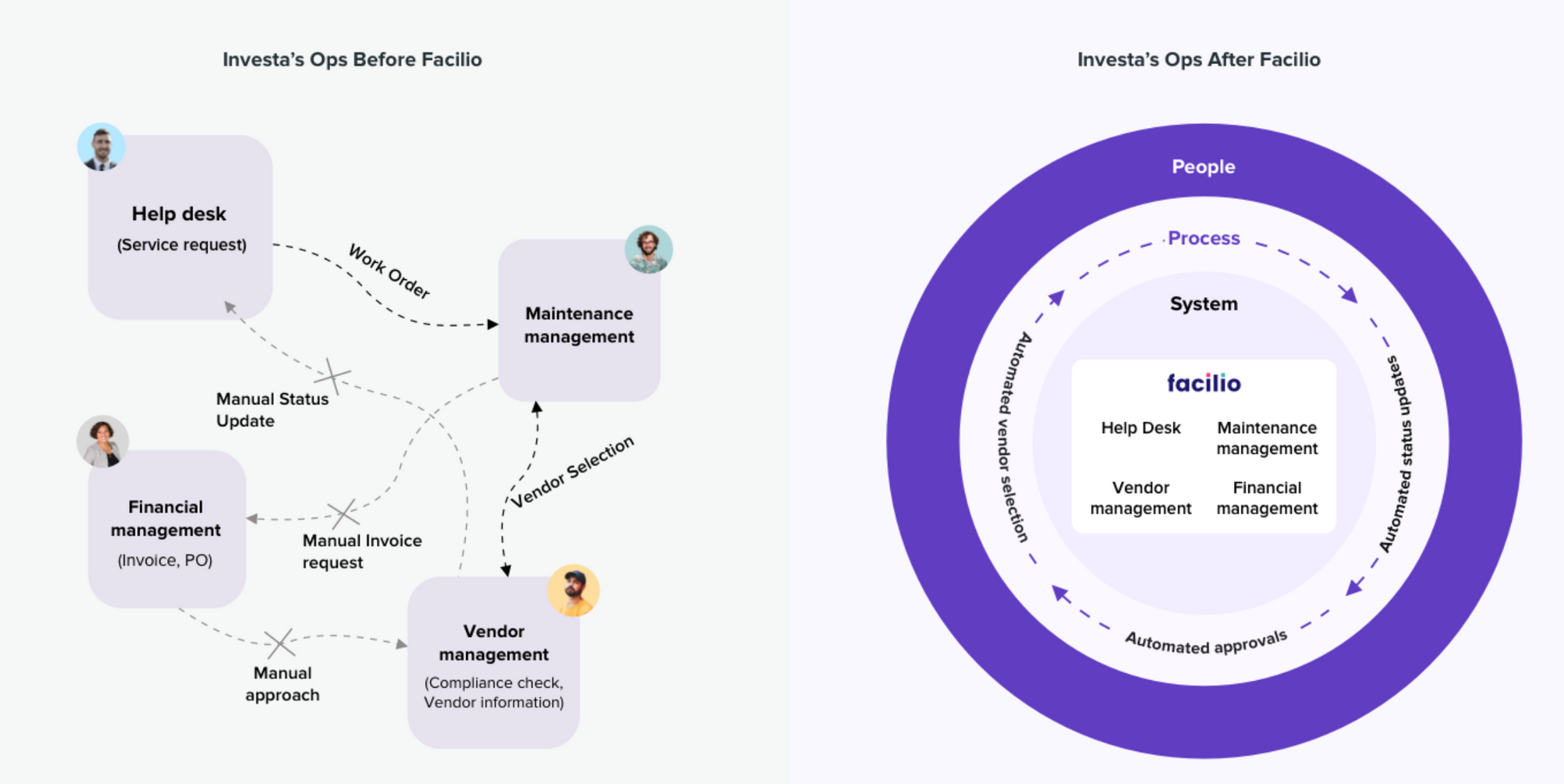

Real-World Results: The Advantage of Using Facilio’s Connected CMMS

Investa implemented Facilio Connected CMMS and cut asset downtime by 40%, while boosting maintenance efficiency and compliance across their commercial real estate portfolio.

See how Investa streamlined operations, and augmented tenant and contractor experience with Facilio’s Connected CMMS

CIT Ltd., Saudi Arabia, deployed enterprise‑wide in just three weeks—gaining fault detection accuracy up 15% and live visibility across assets and work orders

Buy a CMMS that pays for itself

Understanding which CMMS is best for your business involves a deeper understanding of the system's capabilities and alignment with your needs.

Look for a CMMS that offers advanced features like predictive maintenance, condition-based monitoring, and integration with emerging technologies. Consider the system's ability to provide actionable insights and analytics for data-driven decision-making.

This evaluation should also include how vendors structure costs - this CMMS pricing guide breaks down what actually drives pricing and long-term value.

Additionally, seek a CMMS vendor with a track record of delivering excellent customer support, ongoing training opportunities, and continuous system updates to ensure that the CMMS remains effective and aligned with evolving industry trends.

Check out the best practices for evaluating and implementing the right CMMS shared by Investa Property Group, one of Australia's largest commercial real estate companies, which manages over 550,000 square meters.

Or, book a demo with our product experts and see how Facilio can help supercharge your O&M initiatives today!

More from Facilio

![5 Best Facilities Management Software for Schools [2026]](/blog/content/images/size/w600/format/webp/2024/07/Building-managementt--1-.png)