Navigating Refrigerant Compliance Management: A Guide for Retail Managers

If you're in charge of keeping your supermarket's refrigeration systems running smoothly, you must have heard about the Environmental Protection Agency’s (EPA) proposed rule—the HFC Emissions Reduction and Reclamation Rule under the American Innovation and Manufacturing (AIM) Act.

The new rule covers almost all of Section 608's requirements for appliances that use hydrofluorocarbon (HFC)-based refrigerants, including Chronically Leaking Appliances, and also lowers the compliance charge threshold to 15 pounds.

This means that a wider range of supermarket refrigeration systems will now be classified as "chronically leaky." Thus, the number of reportable leaks is likely to dramatically increase, and retail store managers must be proactive about leak detection.

Related Read:

- Refrigerant Leak Detection: Methods of Detection and Regulatory Requirements

- Best Refrigeration Monitoring Systems for Enterprises in 2025

If your retail store or facility violates these regulations, you could face fines of up to $37,500 per day, per violation. For retail managers overseeing multiple properties, these fines can quickly escalate into a compliance headache.

The Internet of Things (IoT) can solve the problem

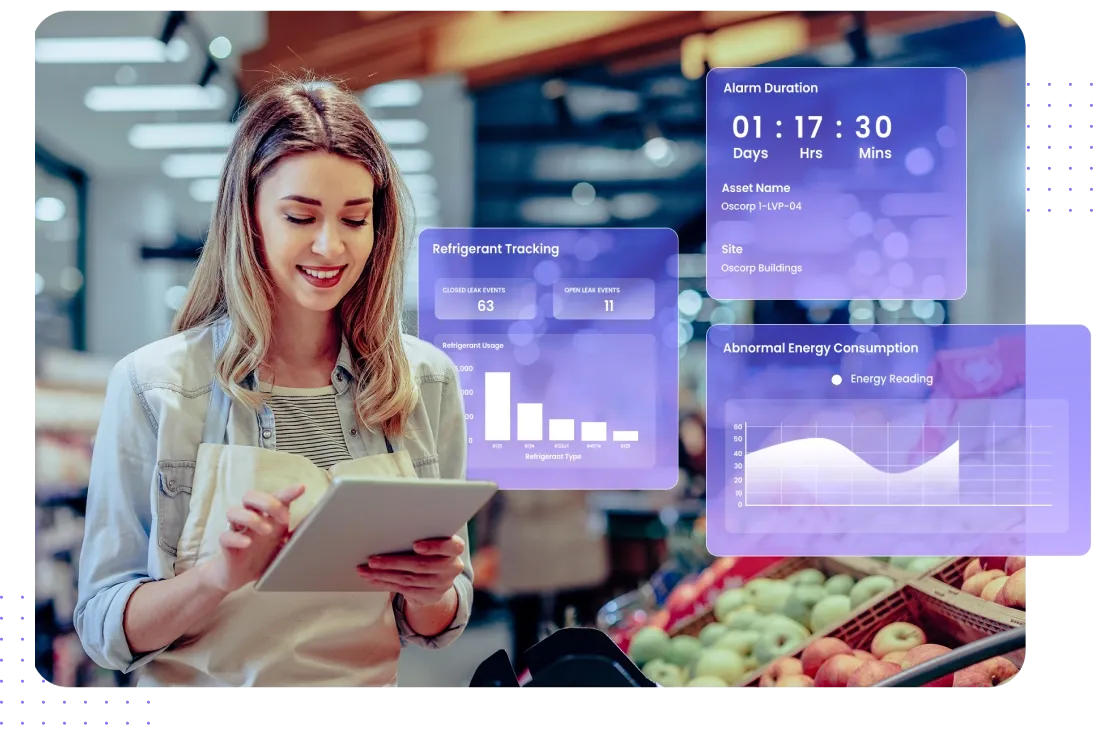

The AIM Act isn't solely about policing leaks; it's focused on prevention. This is where IoT-based leak detection comes into play. IoT has emerged as a mainstream technology capable of detecting issues early and preventing them altogether. Picture penny-sized sensors silently monitoring refrigerant levels, alerting you at the first sign of trouble.

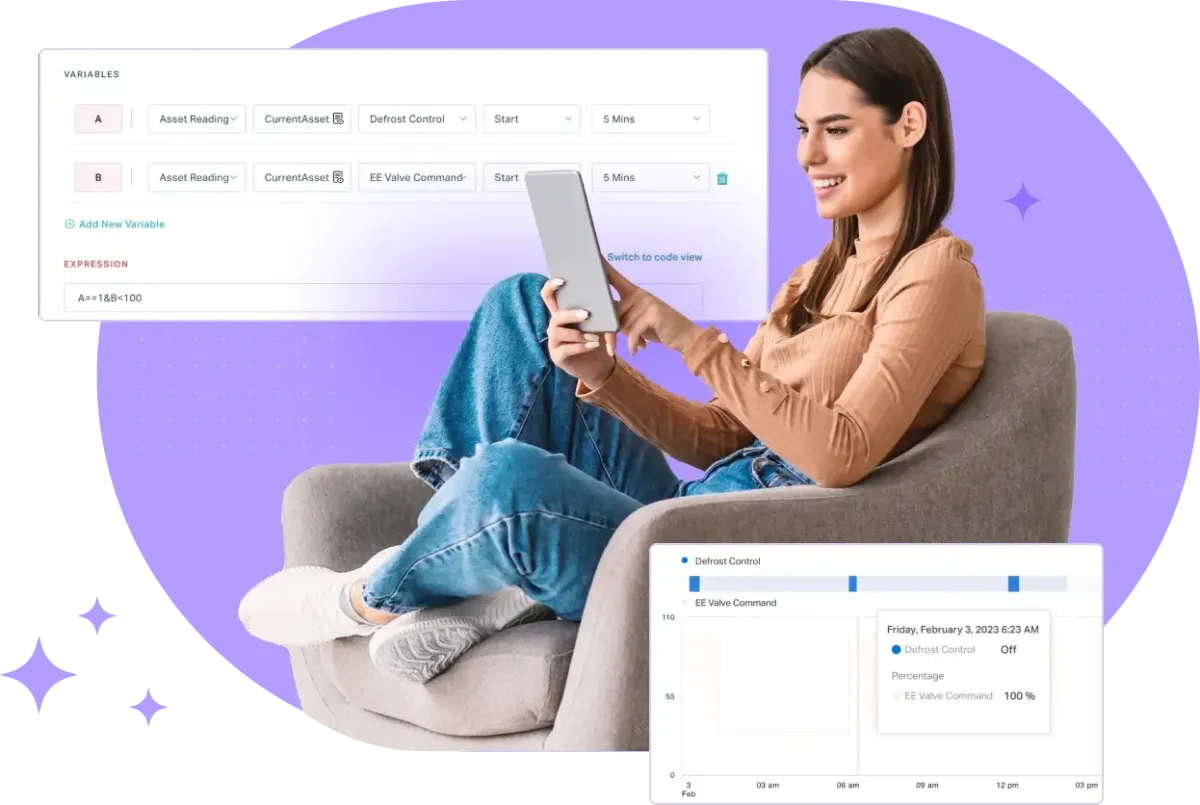

Facilio’s IoT-based, context-driven connected refrigeration solution enables you to detect leaks early. Further, it triggers automated alerts that aid in scheduling maintenance activities to prevent equipment breakdown. It also enables automatic compliance tracking by automating routine inspections and rounds for field service teams.

The AIM Act is intended to protect the climate by reducing the use of HFCs in three ways:

- To phase down the production and use of listed HFCs

- To manage HFCs and their substitutes

- To transition to advanced technologies for leak detection.

As part of refrigerant management, subsection (h) of the AIM Act requires the use of automatic leak detection (ALD) systems.

In this guide, you'll discover the latest updates in refrigerant compliance and learn how to achieve maximum compliance.

What is refrigerant compliance?

Refrigerant compliance refers to the rules and regulations laid down by state or international agencies regarding the use, handling, or disposal of refrigerants.

It is critical for two reasons:

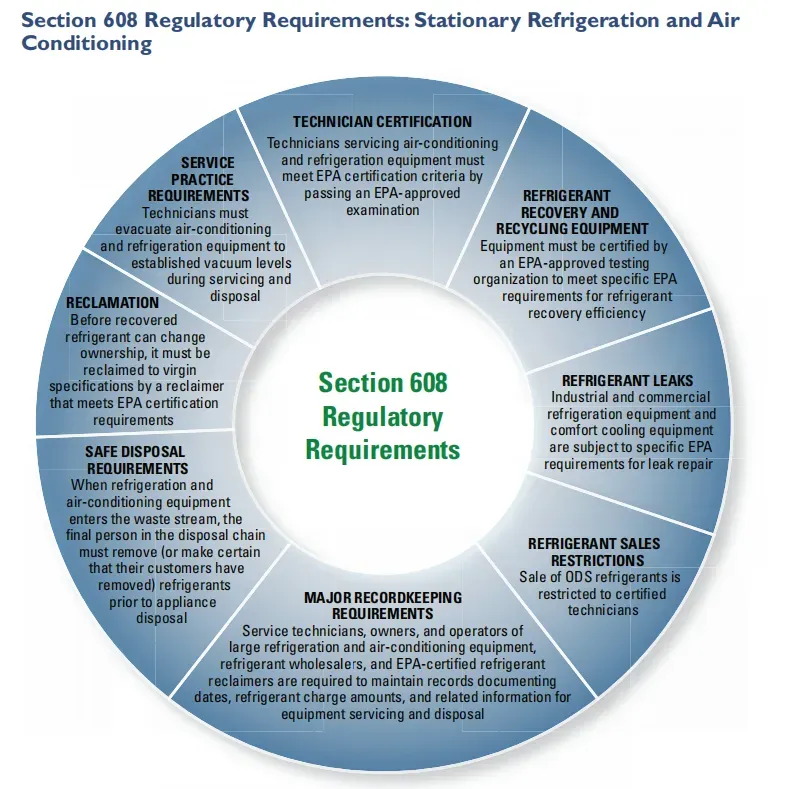

The EPA introduced Section 608 to ensure uniformity in refrigerant compliance in the US. It prescribes the compliance procedures for refrigerant compliance.

What is required of supermarkets, property, and facility managers?

- Calculate the leak rate every time ozone-depleting refrigerant is added to an appliance.

- Conduct leak inspections for appliances that have exceeded the applicable leak.

- Rate (1 shown in table below)

- Identify and repair leaks that exceed the prescribed threshold.

- Retrofit or retire equipment for which leaks cannot be identified or repaired.

- Maintain records and submit reports as required, including:

- Records of all service and maintenance activities performed, including leak rate calculations, leak inspections, and their repair records

- List of equipment that were retrofit or retired

- Proof of technician certifications at the place of business

- Details of persons sending them material for reclamation and details of such materials

- Details of refrigerant used by retailers and wholesalers

For full list of recordkeeping requirements, visit: Recordkeeping and Reporting Requirements for Stationary Refrigeration | US EPA

1 Leak inspection requirements as per Section 608 of the Clean Air Act:

Overview: Refrigerant regulations as per Section 608 of the EPA

Think of Section 608 of the Clean Air Act as your playbook for responsible refrigerant management. By adhering to these standards, you're not only meeting legal requirements but explicitly demonstrating your commitment to sustainability.

Further, it also lays down legal restrictions for sale technician certification, sale of refrigerants to certified technicians, leak inspection, and record-keeping requirements for appliances containing ozone-depleting refrigerants.

It is obvious that complying with Section 608 will be challenging without the right leak detection software. This adds to the existing challenges of addressing irrelevant alarms and managing work orders across point solutions that do not interoperate.

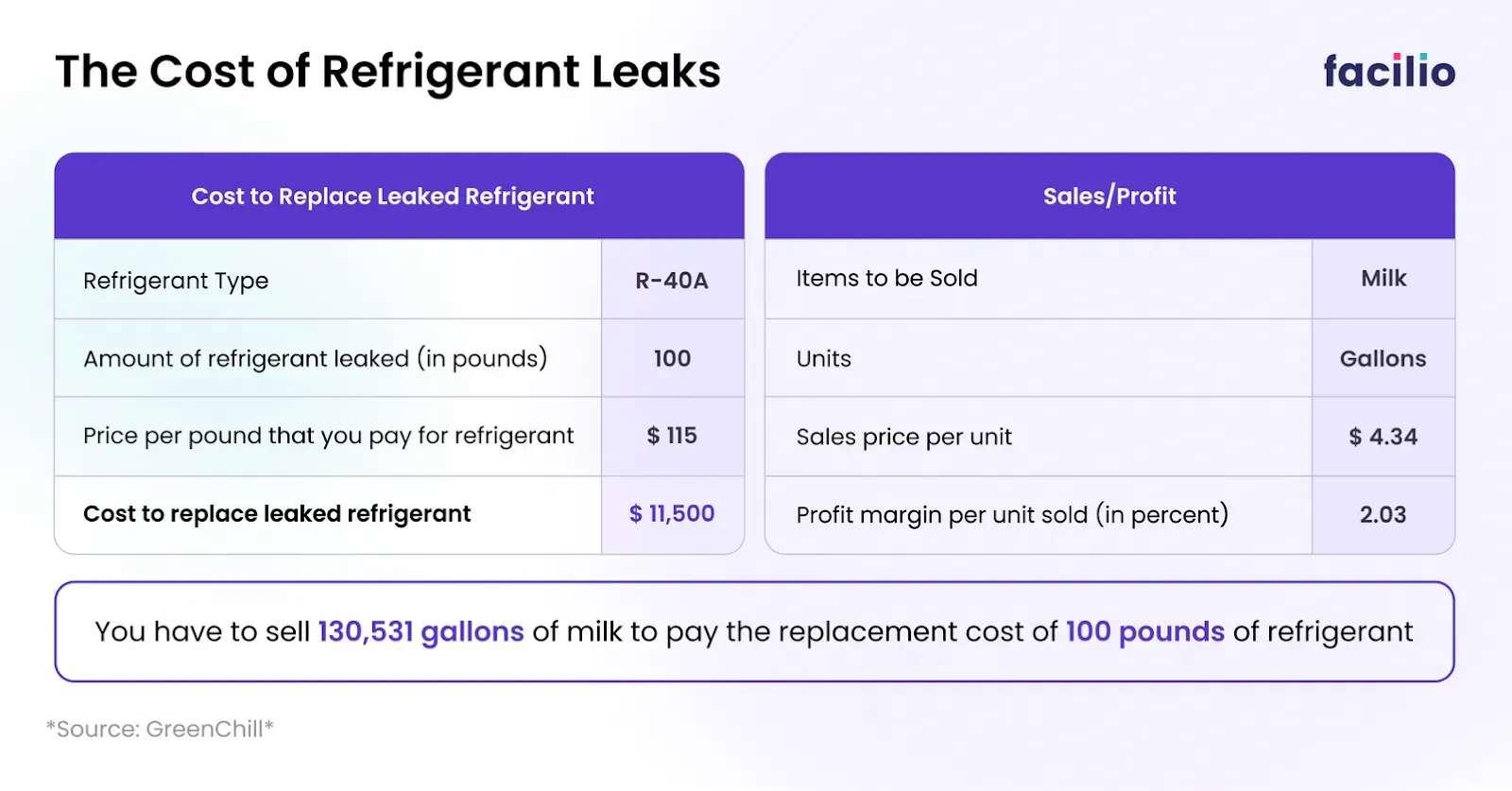

Further, there are costs attached to replacing refrigerant leaks with a severe impact on the bottomline. The image below provides the math:

There are also additional costs like fines for violations of compliance requirements.

All said, managing refrigerant compliance at scale is challenging. The use of software-led optimization is the right way forward. Businesses that have leveraged automation of refrigeration compliance have reaped benefits too, like Tuten labs did.

Case study: How Tuten Labs leveraged Facilio to digitize & automate O&M across 10,000 large format retail stores

Tuten Labs is a technology leader, specializing in reducing energy consumption, emissions, and costs for retail stores while maintaining a consistent in-store experience for end customers.

The team faced several challenges that put their reliability at risk. Here’s a tabular view of how Facilio’s cloud-based, intelligent platform helped overcome them:

The Facilio Impact

The AIM Act

As mentioned previously, the AIM Act directs the EPA to address HFC consumption through two main actions:

Gradual Phasing Down of HFC Consumption

The AIM Act mandates an 85% reduction in HFC production and consumption by 2036 from historic baseline levels. It also gives the EPA more authority to manage HFCs and their substitutes.

The table gives the planned timeline for phasedown of HFCs a, verbatim from Section 608.

Technology Transitions

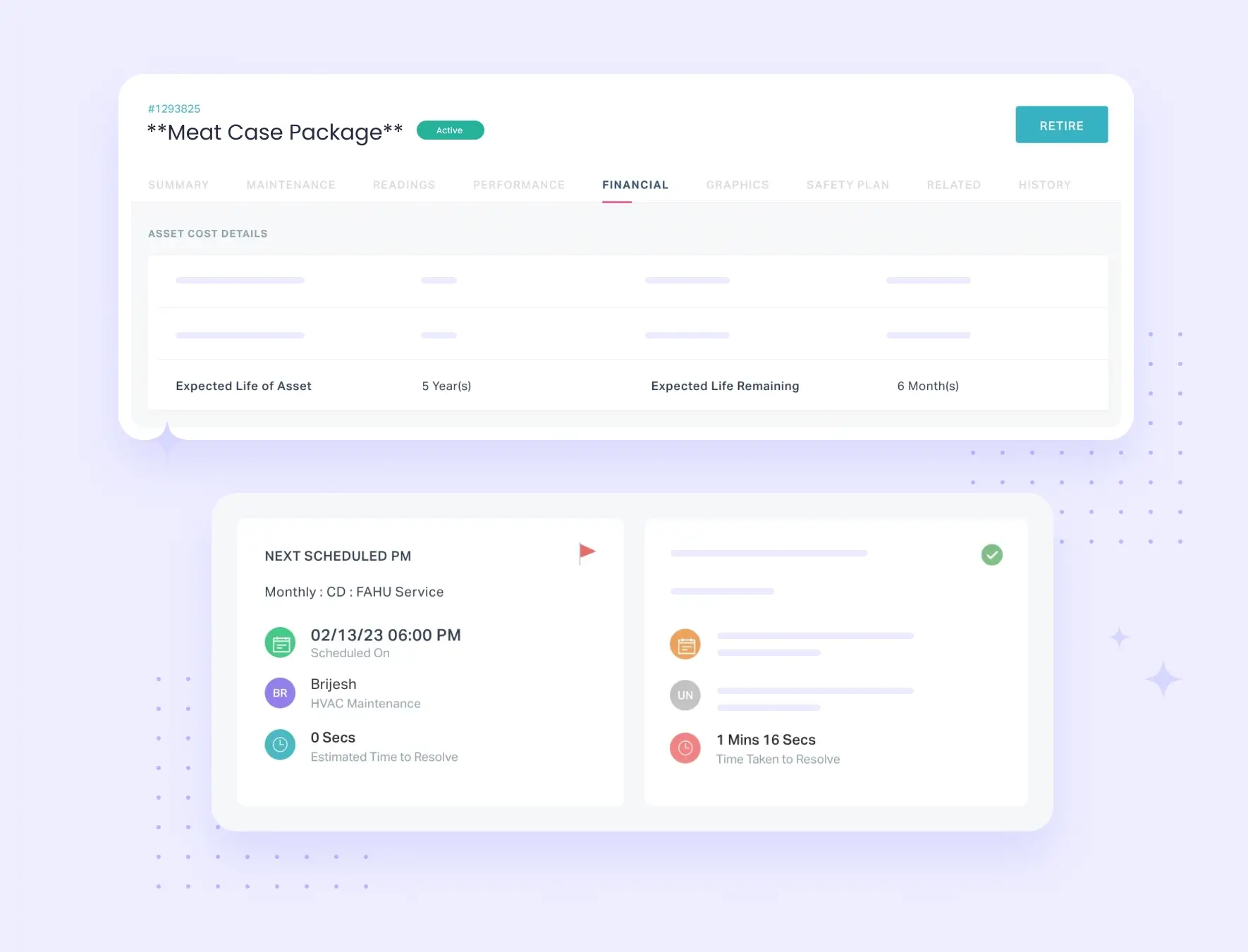

The EPA has released a final “Technology Transitions” rule under the AIM Act, which requires a transition to more efficient and climate-safe technologies. Thus, supermarket and facility managers must retrofit or replace their current equipment. Both demand massive capital investments and the time to ROI often runs into several years. For businesses operating on a thin profit margin, this is a challenge. However, there are alternatives.

What if you could first take stock of your existing equipment, optimize them to make them perform optimally, and then, based on data, make decisions about more capital intensive initiatives? This optimization can be done at scale, which will bring in compounded savings across your portfolio. What’s more, you can recover the cost of acquiring this IoT- and AI-powered refrigeration management software within weeks instead of months.

Learn more: Facilio Debuts Connected Refrigeration Solution | Progressive Grocer

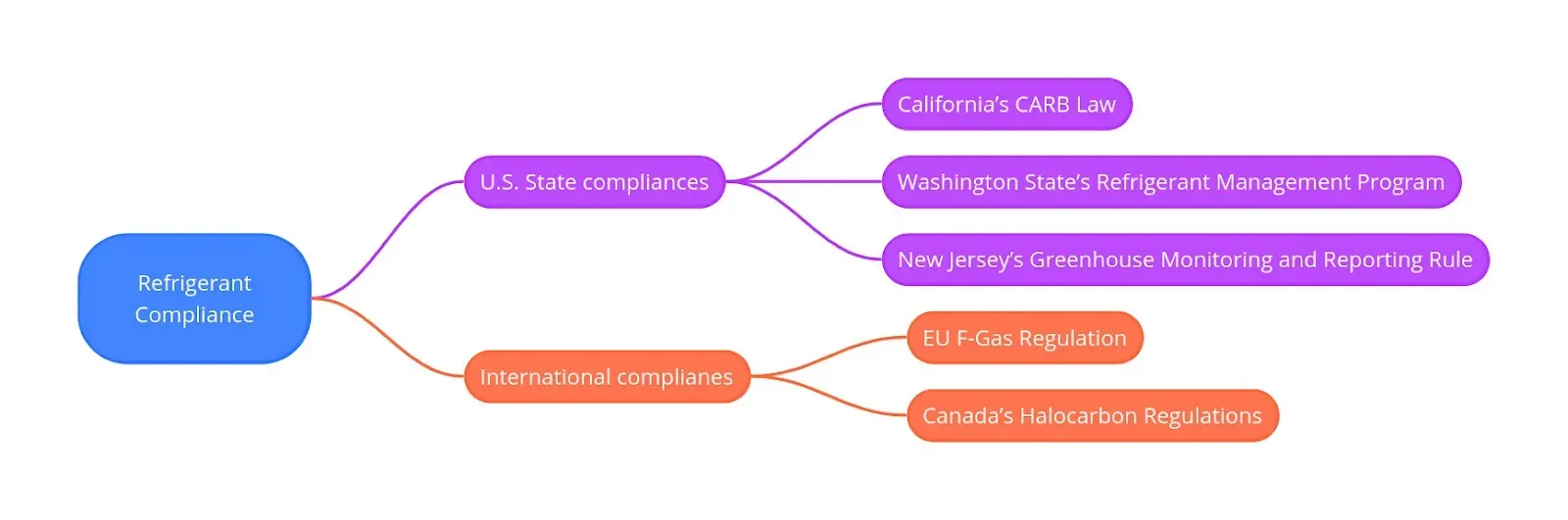

Refrigerant compliance: State and international regulations

The EPA lays down over-arching regulations for every business using refrigerant and cooling systems in the US. At the same time, the States are also allowed to introduce their own laws for managing refrigerant compliance.

Similarly, there are also other international companies that businesses have to bear in mind while managing their facilities located outside the US.

Here are three such State-level refrigerant compliances required in the US:

California’s CARB Law

The California Air Resources Board (CARB) oversees air pollution regulations within the state and are often stricter than EPA standards.

Major requirements:

- All heavy-duty trucks operating anywhere in California or passing through the State, must comply with the CARB law.

- Prescribed public and private companies that meet must disclose their greenhouse gas emissions.

New Jersey’s Greenhouse Monitoring and Reporting Rule

New Jersey’s rule aims to address the gaps in greenhouse gas reporting, especially for methane gases and HFCs.

Major requirements:

- Facilities emitting over 100 tons of methane annually are required to report their emissions.

- The rule covers facilities with refrigeration systems containing 50 pounds or more of high GWP refrigerant charge.

- Natural gas public utilities operating within the state are required to submit an annual Pipeline Modernization Report.

Washington State’s Refrigerant Management Program

Similar to the other state laws, Washington State’s Refrigerant Management Program aims to mitigate climate change impacts caused by refrigerant emissions.

Major requirements:

- Facilities with refrigeration and air conditioning systems containing more than 50 pounds of refrigerant (with a GWP of 150 or more) must conduct periodic leak inspections.

- Records of leak inspections must be kept at site.

- Facility owners are required to plan for a smooth transition to more environmentally friendly refrigerants.

Other international refrigerant compliance regulations

EU F-gas regulation

Regulation put in place by the EU with the goal of reducing fluorinated greenhouse gasses (F-gas) emissions by 67% by 2030.

Learn more: Regulation - EU - 2024/573 - EN - EUR-Lex

Canada’s halocarbon regulations

Recently updated in 2022 which restricts production, import, export, and use of various halocarbons, including HFCs in Canada.

Learn more: Federal Halocarbon Regulations information - Canada.ca

Knowing all these regulations and ensuring their compliance is not going to be easy. If you are attempting to track these compliances manually, you're walking into an operational nightmare.

A better alternative would be to invest in an IoT-based, intelligent refrigerant tracking software that helps ensure compliance at scale.

Intelligent refrigerant compliance and leak detection with Facilio

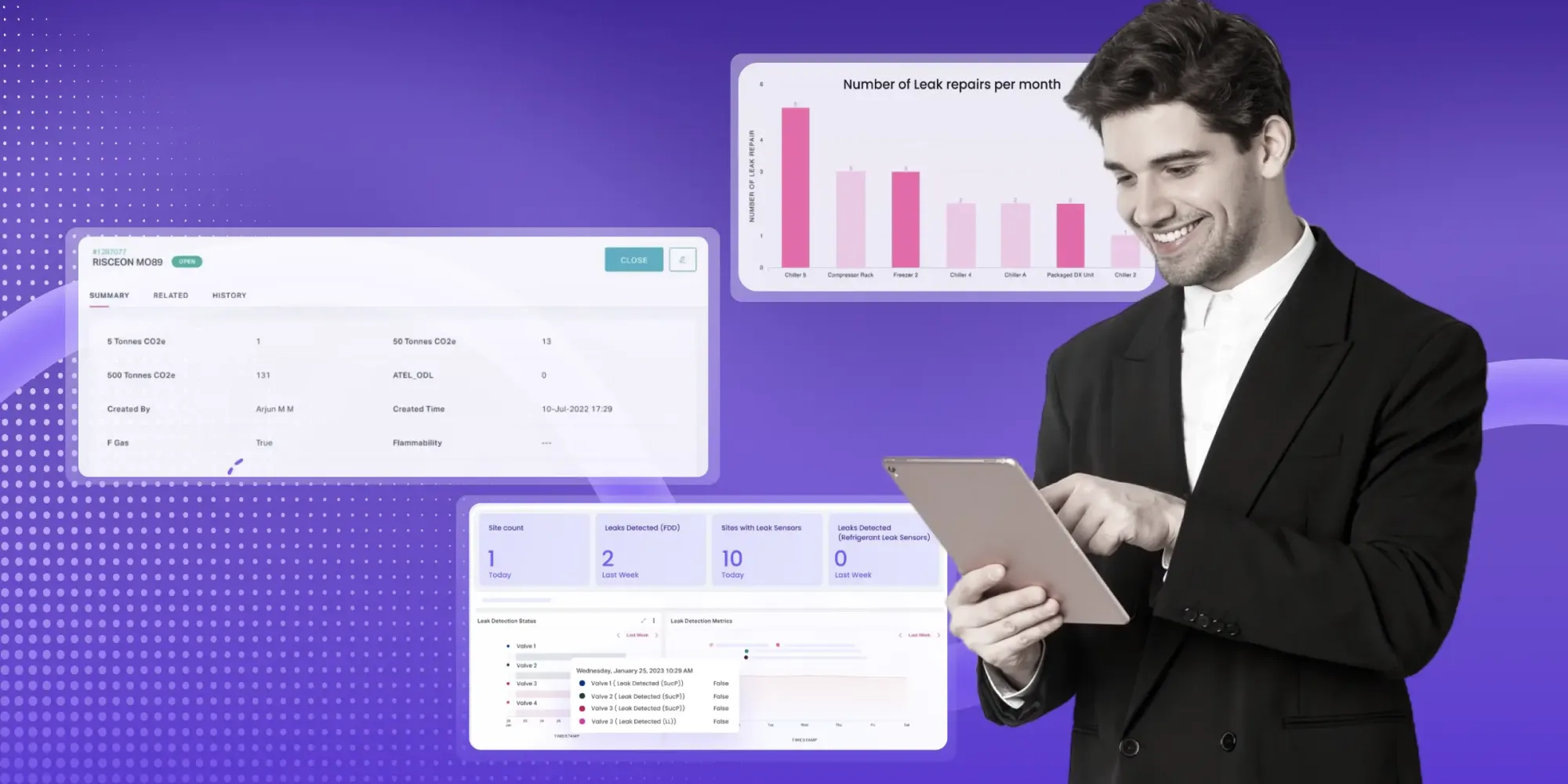

Facilio offers a refrigerant compliance management software with advanced refrigerant compliance and leak detection.

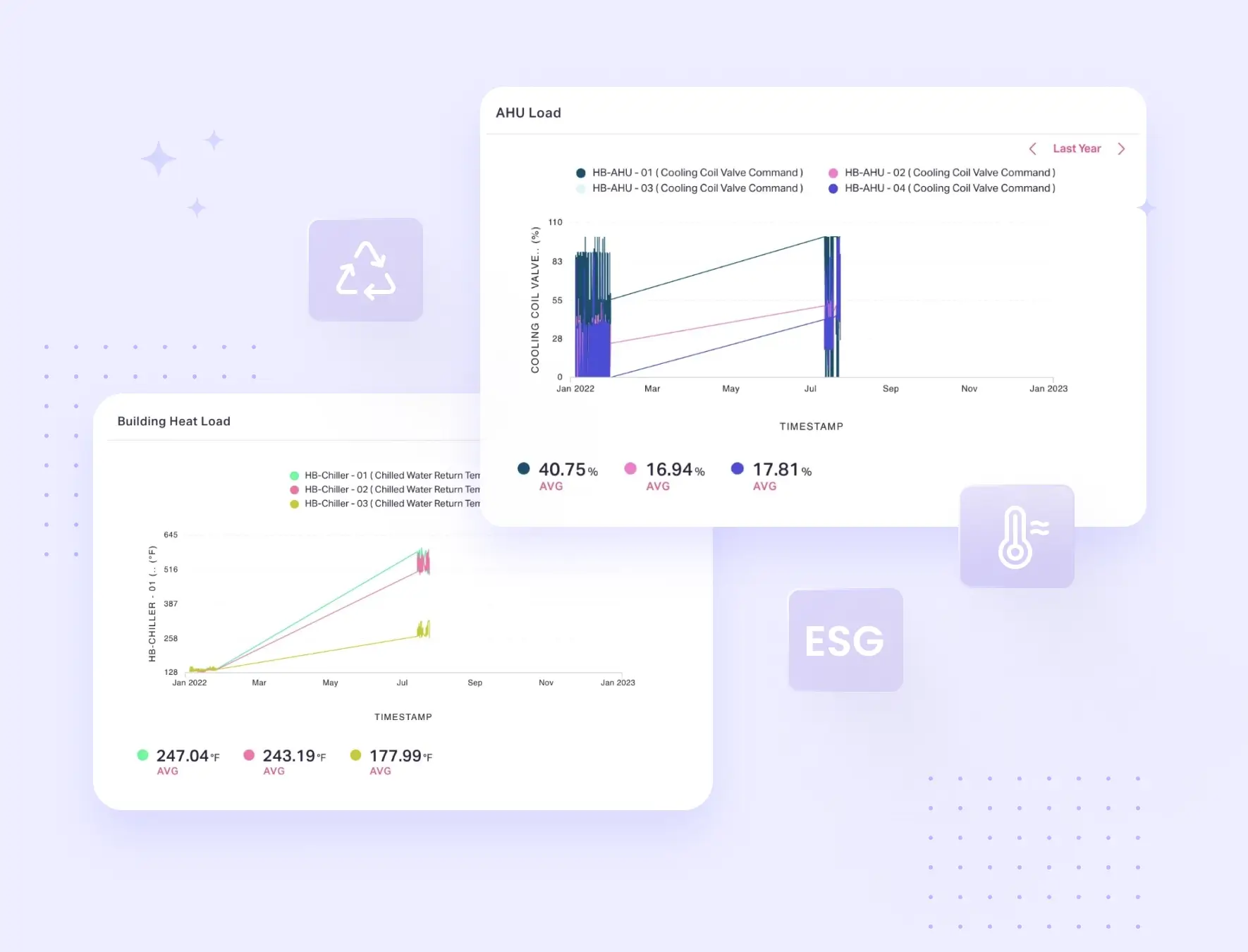

Instead of tacking together point solutions like non-contextual alarm systems, outdated automation software, and business software that do not integrate well, Facilio’s API-first, cloud-based solution allows you to manage people, processes, and systems from a single location.

Here is how it works:

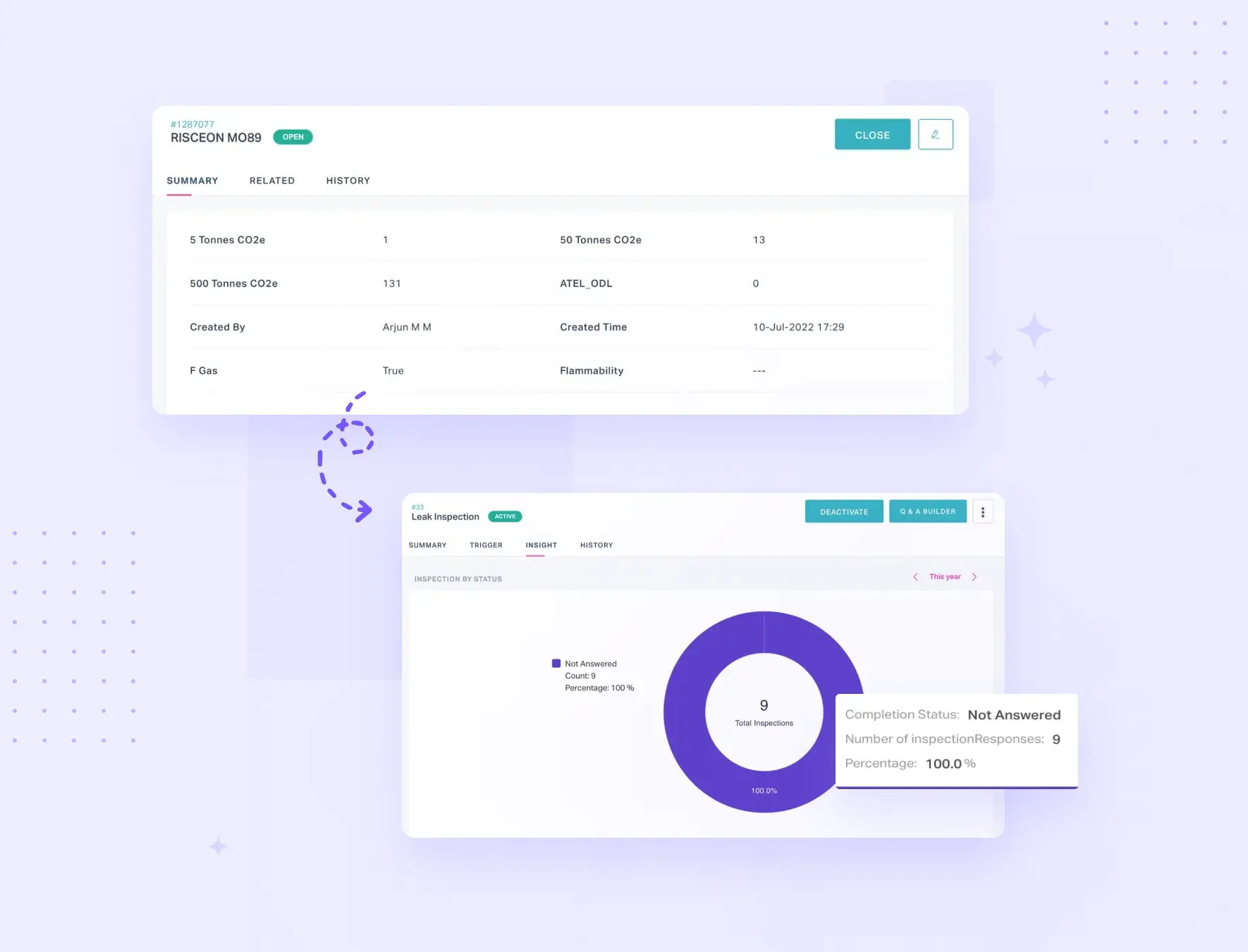

Automated compliance

Facilio automates routine inspections and eliminates manual tracking of compliance requirements across multiple sites. It classifies materials based on quantity, monitors usage history, and streamlines inventory management—all from a centralized platform.

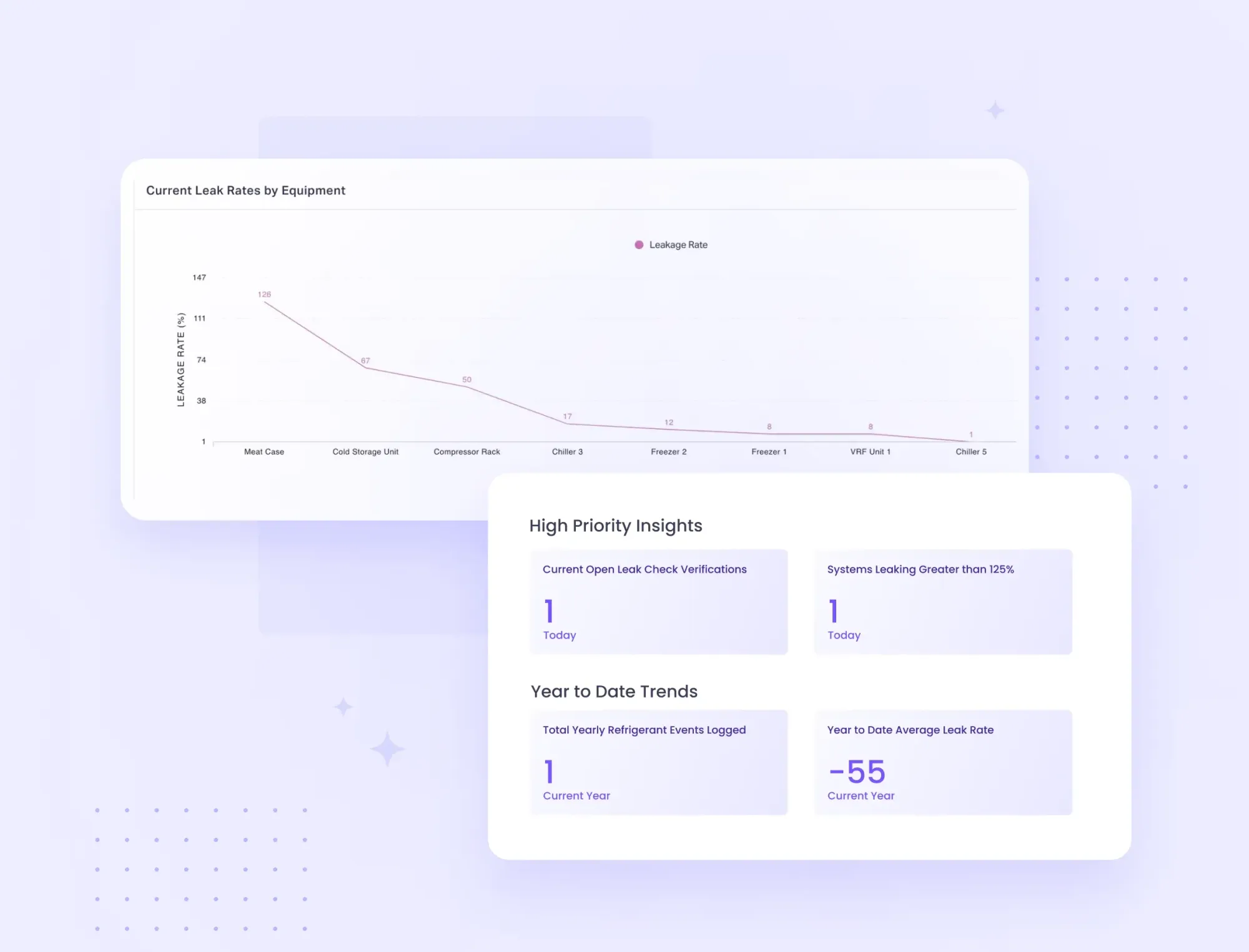

Early detection of leaks

Facilio’s solution detects refrigerant leaks early through IoT-based tracking. It makes connected refrigeration a reality and helps detect leaks proactively. This leads to lower energy consumption and optimized staffing costs.

Compliance & audits

All refrigerant regulations require accurate and timely recordkeeping. With Facilio, you can generate accurate reports for leak rates, refrigerant inventory levels, and other compliance requirements.

ESG governance & sustainability reporting

Facilio digitizes compliance reports, consolidating HVACR data from various sources. Accurate ESG reports track sustainability progress, demonstrating social responsibility. Learn More on Best ESG Reporting Software

In a nutshell, Facilio’s smart refrigeration software ensures compliance, early leak detection, and streamlined reporting via a single-pane-of-glass solution.

More from Facilio