OEE: A Facility Manager's Guide to Optimizing Asset Performance

Key takeaways

- Although OEE originated in the manufacturing sector, its fundamental concepts are equally applicable to the FM industry, so facility managers can utilize OEE to assess their operational efficiency and pinpoint opportunities for enhancement thoroughly.

- By focusing on the key components of OEE, namely availability, performance, and quality of your assets, you can align your maintenance strategies with data-driven insights, ensuring your facilities function efficiently.

- Connected CaFM solutions are transforming how Facility Management Service Providers (FMSPs) operate, addressing long-standing challenges posed by outdated systems in improving and optimizing OEE.

- With automated workflows and predictive maintenance, facilities not only operate more efficiently but also support proactive maintenance to mitigate big losses and enhance asset reliability.

In the fictional town of Facilityville, every piece of equipment, from HVAC systems to refrigerators and elevators, is a key player. However, in this setting, it is not just about achieving efficiency but also spotting inefficiencies and potential breakdowns that can stop operations on track.

This is precisely where OEE steps into the picture and transforms raw data into actionable insights, guiding FMSPs toward optimal asset management.

But how exactly does it help achieve that? With the help of its key components.

Decoding the key components of OEE

Availability, Performance, and Quality serve as the pillars of OEE, providing a holistic view of how resources operate within a facility.

- Availability: This aspect would consider the system's operational uptime relative to scheduled operational hours, acknowledging both planned maintenance and unexpected outages.

- Performance: This component of OEE gauges an asset’s actual output compared to its designed capacity, focusing on elements like energy consumption, ideal cycle time, etc.

- Quality: This specific component determines the percentage of output that aligns with quality standards. Quality parameters may range from indoor air purity, thermal comfort levels, or lighting adequacy.

Now that we have an idea of the three components that make up the well-crafted OEE puzzle, but why on earth should facility managers care about it?

The importance of OEE in modern facility management

When it comes to modern facility management, OEE is like a secret weapon for anyone who manages a facility. It is important because OEE offers:

- Enhanced productivity: In an environment where even fine-tuned machines have hiccups slowing things down, it helps spot root causes irrespective of whether it is an equipment-related issue or a problematic process.

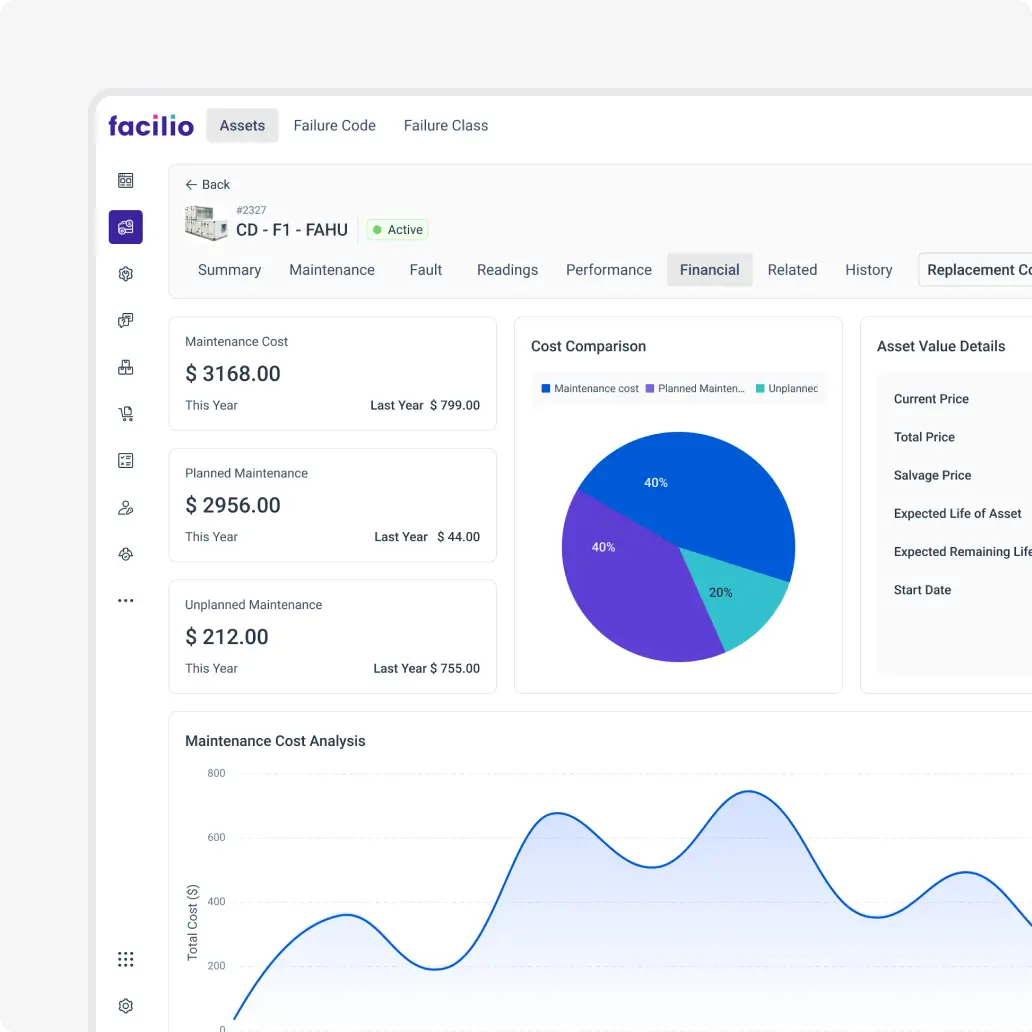

- Cost-saving opportunities: Maintaining a facility and keeping it running is expensive. OEE takes into account the areas for improvement, such as total spend on repair, wasted energy, and more, paving the way for cost savings.

- Improved occupant comfort: OEE helps facility managers go one step beyond the occupant experience and helps everyone in the building stay comfortable and productive by keeping things running at the right speed.

- Actionable insights: Unlike other metrics, OEE helps stakeholders get a bird’s eye view of their portfolio so that they can make smart choices on how to manage equipment, plan maintenance of assets, and improve OEE scores.

- Continuous improvement: Most importantly, this is not just a once-and-done exercise. By keeping an eye on this metric, FMs can find innovative ways to keep their assets constantly running at the top shape.

Now that we understand the importance of OEE, how do you calculate it?

A step-by-step guide to calculating OEE

Applying the OEE formula within facility management contexts provides a targeted approach to asset optimization. By focusing specifically on assets rather than the entire building's operation, facility managers can gain a clearer picture of potential improvement areas.

Each component of OEE—Availability, Performance, and Quality—translates directly to the functions and operations of assets and other building equipment. To calculate OEE perfectly, you need to determine availability, performance, and quality and establish some ground rules.

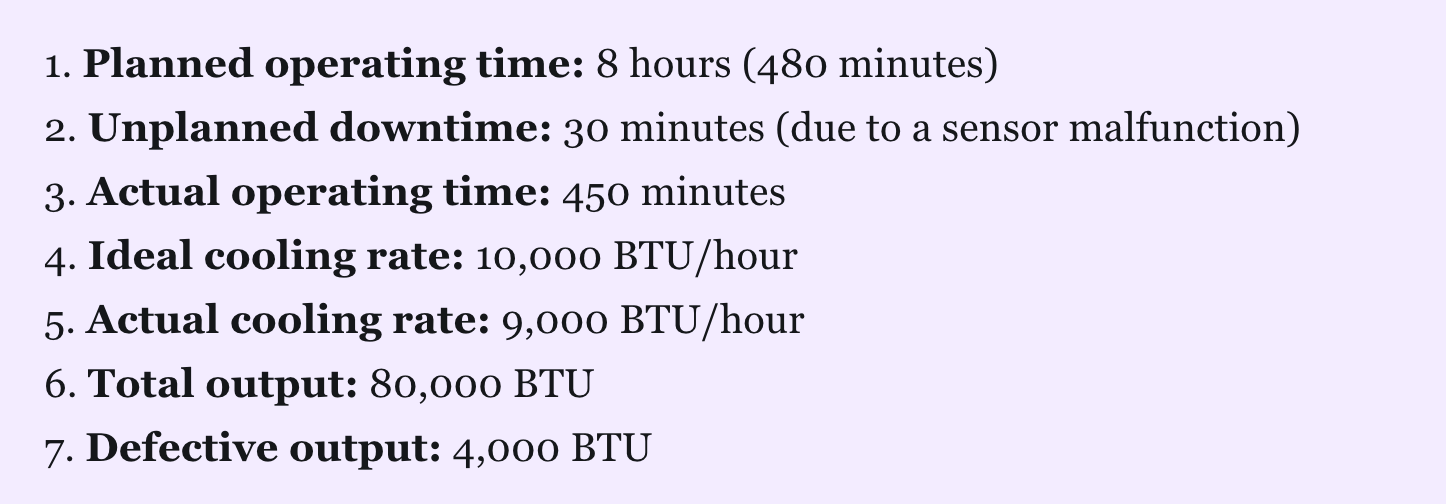

- Gather required data

Establish the total operational hours planned for the asset and the collect other information listed below.

- Calculate Availability

Availability = (Planned Production Time - Downtime) / Planned Production Time

- Calculate Performance

Performance = Actual Speed / Ideal Speed

- Calculate Quality

Quality = Acceptable Units / Total Units Produced

- Calculate OEE

The formula looks easy, but how do you go about applying it to actual assets in your facilities?

Understanding the OEE formula in the facility context

We all know that workplaces often rely heavily on the HVAC system to ensure comfortable work conditions around the clock. However, despite the expectations, like all machinery, HVAC systems do encounter interruptions.

Let us assume that the HVAC system, in this case, halts for 4 hours in a day, reducing its operational time to just 20 hours. When it's running, it's supposed to circulate 60 units of air per hour (think of these as "units of coolness"). However, due to some minor issues like a slightly clogged filter, it only manages to circulate 54 units per hour on average.

Now, of all the air circulated that day (which is 20 hours x 54 units/hour = 1080 units), a small portion wasn't properly conditioned - maybe some areas were a bit too warm or too cool. Only 1030 units met the perfect temperature and quality standards.

With all this information, let us get down to calculating OEE and start by mapping out its key components.

- Availability: This looks at how much the system was actually running compared to its total time of operation. Here, it's 20 hours out of 24, giving us 83.3% availability.

- Performance: This measures how well the system worked when it was running. It circulated 54 units per hour instead of the ideal 60, resulting in 90% performance.

- Quality: This checks how much of the output was "good." With 1030 good units out of 1080 total, we get 95.37% with some quality losses.

To get the overall OEE, we multiply these three together: 83.3% x 90% x 95.37% = 71.3%.

This means the HVAC system is running at 71.3% of its full potential!

Knowing this, the facility manager can investigate why there was a slow cycle, why the performance wasn't perfect, and where the HVAC system’s performance fell short.

That’s great, but how do you measure all these elements with your existing CaFM?

Legacy vs. connected CaFM in OEE measurement

In the past, FMSPs relied heavily on fragmented legacy CaFM and stitched out the gaps with manual processes. This disconnected approach led to data and communication silos, limited visibility, and a reactive maintenance curve where they relied on human intervention to track equipment performance.

However, they were constantly firefighting suboptimal asset utilization and frequent equipment downtime.

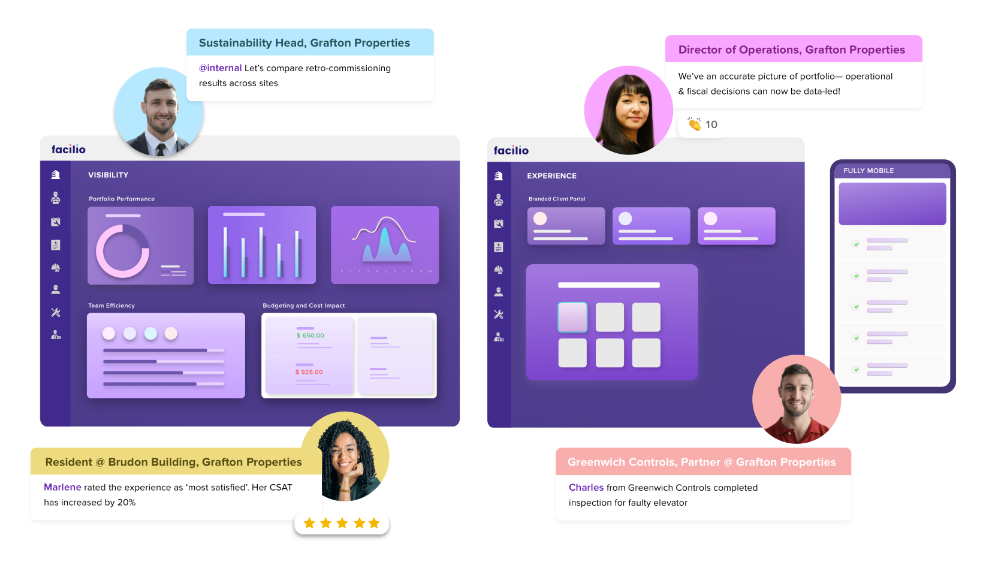

Connected CaFMs like Facilio break down data silos and offer a centralized platform for real-time asset monitoring, performance analysis, and decision-making. Here's how connected CaFMs help unlock OEE’s real potential.

Facilio's connected CaFM: Enhancing OEE for facility management

By merging data from various building systems, sensors, and meters, Connected CaFMs like Facilio offer a comprehensive view of operational performance, enabling real-time oversight, insightful analysis, and informed decision-making.

Facilitating tech-driven client relationships

Facilio strengthens client relationships by leveraging technology to provide transparency and superior service delivery, thereby indirectly enhancing OEE.

- Client portal access: Offering clients real-time insights into maintenance progress and asset status fosters trust and engagement.

- Feedback mechanisms: Integrated feedback loops right within the maintenance ticketing system allow constant evaluation and improvement of services provided, aligning with client needs.

Streamlining total productive maintenance

On top of this, when OEE is combined with total productive maintenance (TPM) strategies, it can create a powerful framework for enterprise asset management as TPM’s emphasis on empowering operators to maintain equipment aligns with OEE’s data-driven insights.

- Proactive maintenance scheduling: Facilio automates maintenance schedules based on equipment usage data, enhancing facility maintenance and extending asset lifespan.

- Enhanced collaboration: With real-time data accessibility, teams can better coordinate and communicate, enhancing maintenance execution efficiency.

- Rapid incident response: Facilio’s platform ensures quick identification and resolution of issues, minimizing operational disruptions.

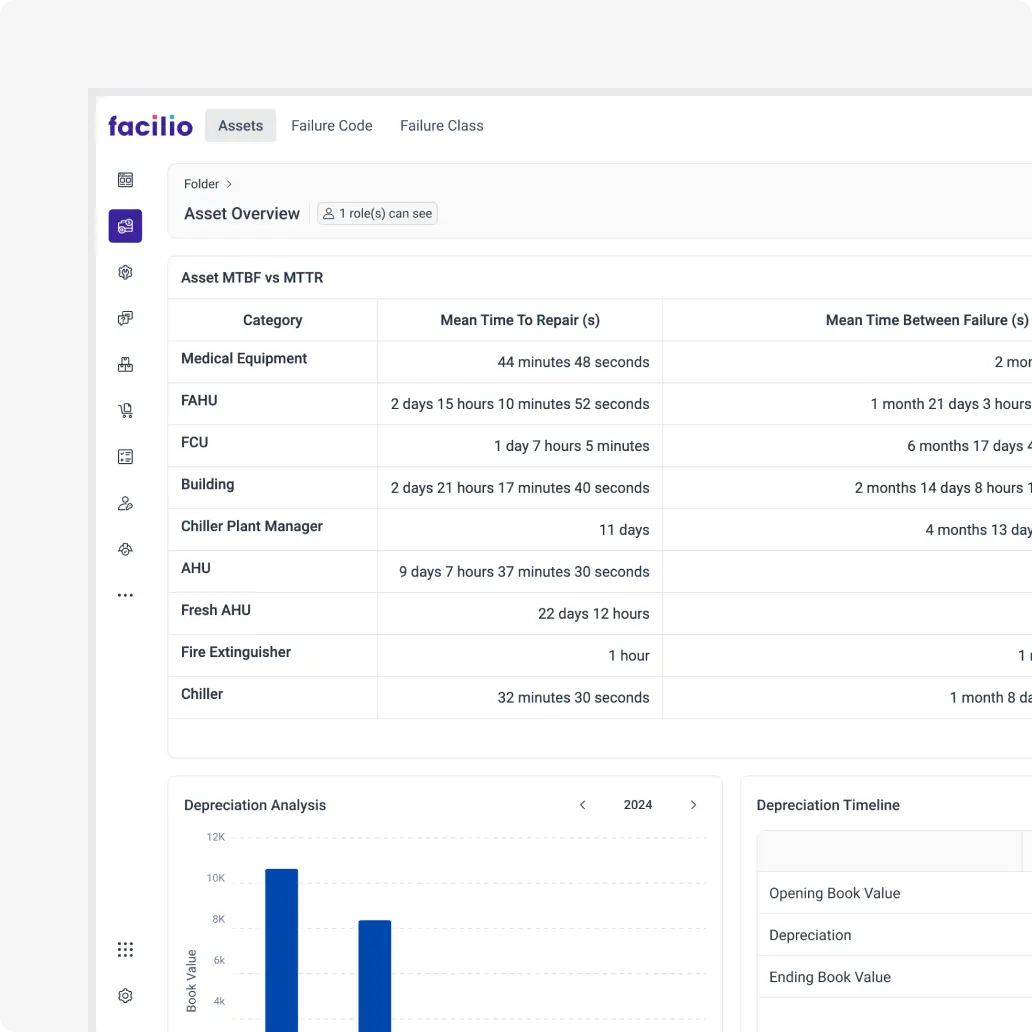

Enhancing equipment reliability

By leveraging predictive analytics, Facilio enhances the reliability of critical building systems, which is a cornerstone of improving OEE.

- Real-time monitoring: Facilio continuously monitors asset health and performance, ensuring immediate response to any anomalies.

- Predictive fault detection: Facilio uses historical and real-time data to detect and predict equipment failures, enabling preemptive action.

- Advanced diagnostics: Using machine learning (ML) algorithms, Facilio conducts detailed diagnostics, eliminating waste of operational hours and preventing potential disruptions.

Optimizing facility maintenance with data-driven KPIs

Facilio's CaFM provides invaluable insights by tracking and analyzing critical maintenance KPIs like mean time between failure, equipment availability, mean time to repair, and more, helping facility managers focus on critical areas that impact OEE.

- Comprehensive KPI dashboard: Facility managers can easily access and analyze key metrics, identifying trends and actionable insights for process improvements.

- Data-driven decision making: Facilio's analytics framework supports informed decision-making and enhances maintenance strategies.

- Continuous improvement: Encourage ongoing enhancement by regularly reviewing OEE data to identify new optimization opportunities and implement corrective measures.

Implementing preventive maintenance strategies

Facilio's platform emphasizes preventive maintenance as a key strategy for maximizing asset availability and performance, which are crucial components of OEE.

- Scheduled maintenance alerts: Facilio automatically generates alerts for scheduled maintenance, ensuring timely actions and minimizing potential failures.

- Resource optimization: Our CaFM platform helps allocate resources efficiently, ensuring that maintenance teams can promptly address critical tasks.

Enhancing operational efficiency seamlessly

Facilio implements CaFM best practices to ensure seamless operation and maintenance processes, contributing to optimized OEE.

- Efficient work order management: Facilio automates work orders, reducing manual input and errors, and streamlining maintenance workflows.

- Robust integrations: The platform offers seamless integration capabilities with existing systems for a unified facility management solution.

Final thoughts

Looking at OEE with the help of a connected CaFM can empower FMSPs to optimize building operations and attain long-term sustainability. A connected CaFM integrates seamlessly with building management systems, automating predictive maintenance, streamlining fault detection and diagnostics, and optimizing asset utilization.

As the facility management industry evolves to embrace data-centric solutions, CaFM becomes vital. Explore Facilio’s connected CaFM solutions to see how they can help elevate your facility management operations and foster a conducive environment for continuous improvement.

More from Facilio