You May be Wasting Time & Money on Overly Frequent Inspections

Maintenance inspections are crucial for ensuring the safety, reliability, and longevity of your facility's equipment and infrastructure.

However, the conventional wisdom that frequent inspections are always better is misguided and can lead to unnecessary expenses and disruptions.

In this article, we challenge these assumptions and offer a more efficient and cost-effective approach to running maintenance inspections in your facility.

5 things about maintenance inspections you need to know in 2023

Maintenance inspections can sometimes create a false sense of security, and organizations that rely too heavily on inspections may start to assume that their equipment is functioning perfectly, even when it's not. This can lead to complacency and a lack of preparedness when problems do arise.

Maintenance inspections are absolutely essential, but they might not be working as intended with paper-based processes, and you don't have very good quality data.

Fortunately, there's an app for everything.

Instead of investing more in the number of maintenance inspections for enhanced equipment security & reliability, you could simply automate them and give your inspectors an easy way to verify and record findings on the go.

Further, automated inspections enable real-time monitoring, giving you better data for advanced techniques like predictive and condition-based maintenance.

Prevention is better than cure, but a prediction keeps you ahead in the game.

Here are 5 helpful tips you should keep in mind before you schedule the next inspection:

1. The law of diminishing returns in maintenance inspections

Many facility managers assume that the more frequently they conduct maintenance inspections, the better they will be able to prevent equipment failures and breakdowns and achieve perfect maintenance inspections.

However, this approach ignores the law of diminishing returns, which states that at a certain point, the marginal benefit of an additional inspection becomes smaller than the cost of conducting it.

Also, perfect maintenance inspections are a myth.

Instead of pouring time and resources into inspections that don't add much value, you should focus on identifying the optimal inspection frequency for each type of equipment and infrastructure in your facility.

2. The importance of Root Cause Analysis (RCA)

Another mistake that many facility managers make is relying solely on inspections to identify and fix problems.

While inspections can help detect symptoms of equipment or infrastructure issues, they often do not address the root cause of the problem.

To truly prevent failures and breakdowns, you need to conduct root cause analysis to identify and address the underlying issues that lead to equipment and infrastructure failures.

3. The role of predictive analytics in maintenance inspections

Rather than relying solely on preventive maintenance based on pre-determined schedules, facility managers should embrace predictive maintenance techniques that use data and analytics to identify potential issues before they occur.

By collecting and analyzing data from equipment and infrastructure sensors, you can identify patterns and trends that can help predict when maintenance is needed.

You can identify patterns and trends that help predict when maintenance might be needed by collecting and analyzing operating condition data from equipment and infrastructure via various sensors.

This approach helps reduce the frequency of inspections while improving their accuracy and effectiveness.

Suggested read: What is condition-based maintenance? Strategy 101

4. The power of automation and technology

One of the biggest challenges of running maintenance inspections is the time and resources required to conduct them.

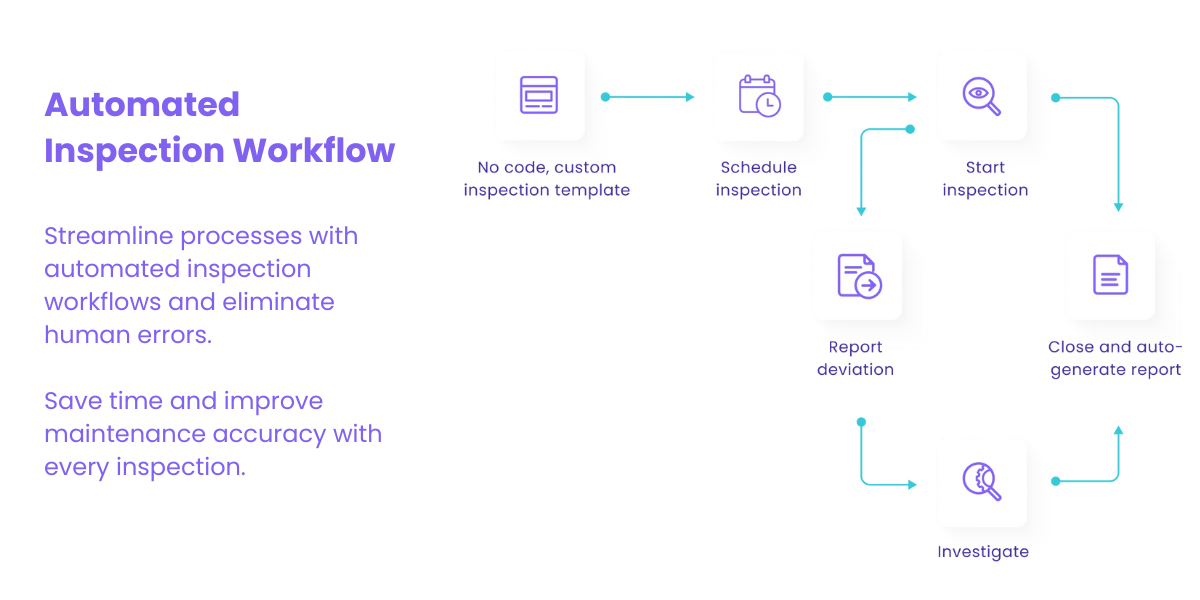

However, with the advent of automation and technology, facility managers can now streamline and automate many of the inspection processes.

For example, using drones, robots, or other remote sensors can help conduct inspections faster, more accurately, and at a lower cost than traditional methods.

Further, with CMMS software like Facilio, you can automate any repetitive processes with powerful workflow orchestrations and eliminate bottlenecks and communication gaps in your processes.

5. The need for continuous improvement and feedback loops

Finally, to truly optimize your maintenance inspections, you need to embrace a culture of continuous improvement and feedback loops.

By regularly reviewing and evaluating your inspection processes, you can identify areas for improvement and make data-driven decisions to optimize your approach.

This approach can help you identify potential cost savings, reduce downtime, and improve the overall safety and reliability of your facility's equipment and infrastructure.

How to effectively conduct maintenance inspections?

Scheduled inspections have long been the standard method for conducting maintenance inspections. However, this approach has some significant flaws.

- First, it assumes that all equipment and systems require the same level of inspection, which is not true.

- Second, it does not account for the possibility of equipment failure between inspections.

- Finally, scheduled inspections can be costly, especially if they require shutting down equipment.

Instead of relying on scheduled or reactive inspections, facility managers should consider a condition-based approach to maintenance inspections.

This method uses predictive analytics to determine when equipment needs to be inspected based on its condition.

By focusing on equipment that needs attention, facility managers can save time and money while ensuring that critical systems are always operational.

Instead, a condition-based approach using predictive analytics and a holistic approach to maintenance inspections is more efficient, cost-effective, and reliable.

Adopting this approach can help facility managers save time and money, prevent equipment failures, and ensure the long-term sustainability of their facilities.

Suggested read: Your CMMS should keep you audit ready, always

Automating maintenance inspections with a CMMS

The right CMMS can help you automate inspections, work order management, vendor management, field service, and inventory management to streamline maintenance management processes and take a big leap toward achieving operational excellence.

Here's what Facilio's CMMS can do to fool-proof and automate your maintenance inspections completely -

Facilio enables swift inspection handling with on-the-go custom digital checklists (that you can make with zero code!) so you can record accurate scores that reflect the health of an asset, space, or site.

Encourage inspectors to report outcomes instantly using a simple mobile app with supporting images, files, and other multimedia, so you never get pencil whipped again or get bogged down with error-prone paper-based processes.

Ensure audit readiness with templated (and customizable) inspections that enhance safety, quality, and compliance and standardize inspection processes across your portfolio.

Finally, you can also automate maintenance inspection schedules to ensure on-time checks to identify any deviations from ideal conditions, then address any concerns with automated ad-hoc work order submissions.

Mitigate risks, ensure safety for people in your facilities, and enhance your organization's reputation; give your team the right CMMS to make it happen!

Let your inspections run on auto-pilot

Book a demoMore from Facilio