Maintenance has moved far beyond manual checklists, reactive repairs, and scattered spreadsheets.

Most teams now look to a CMMS to modernize operations, but then face familiar questions: Which platform fits best?

How do we get teams on board?

How do we prove ROI and sustain it?

It’s no surprise that many CMMS implementations fail to deliver their full value.

But with the right structure, the payoff is significant: less downtime, better asset performance, and clearer visibility across sites.

This guide breaks down exactly how to implement a CMMS the right way, step by step.

CMMS implementation failures and why they happen

Most CMMS projects don’t fail because of the software. They fail because the implementation runs into familiar, avoidable pitfalls. After working with dozens of teams, these are the patterns that keep showing up.

1. Vague scope and misaligned expectations

When teams jump in without a clear business case, measurable KPIs, or defined outcomes, the CMMS quickly becomes a digital filing cabinet. A vague scope leads to confusion, rework, and frustration on all sides.

Fix it: Start with a tightly defined business case, success metrics, and clear entry–exit criteria for every stage.

2. Poor data readiness

Bad or incomplete data is one of the biggest reasons CMMS rollouts stall. Missing asset histories, unstructured naming conventions, and outdated inventory records make the system unreliable from day one.

Fix it: Audit, clean, and standardize your data before migration. Good data accelerates adoption, reporting, and forecasting.

3. Clunky integrations with legacy systems

A CMMS that lives in isolation creates more manual work, not less. When work orders, procurement, or inventory data can’t flow across ERP or IoT systems, the operational picture becomes fragmented.

Fix it: Prioritize integration planning early, especially if you rely on ERP, BMS, or procurement systems.

4. Over-customizing too early

It’s tempting to build everything at once: custom workflows, dashboards, automations, and integrations. But over-customization increases complexity, slows adoption, and leads to technical debt.

Fix it: Roll out core workflows first, validate them in the field, then scale gradually.

5. Resistance to change from site teams

Even the best CMMS fails if the people using it don’t adopt it. Teams often see new systems as extra work or a threat to their routine. Without structured change management, adoption drops quickly.

Fix it: Invest in ongoing training, communicate wins early, and involve technicians in the design of real workflows.

6. Lack of continuous governance and shared ownership

A CMMS isn’t a one-and-done project. Without governance, regular KPI reviews, and clear ownership, the system becomes stale and underused.

Fix it: Establish governance roles, a steady meeting cadence, and a process for evaluating changes before go-live.

7. Missing visibility and slow issue escalation

When teams can’t see project progress, blockers, or decisions, delays stack up fast.

Fix it: Adopt a structured governance model with transparent decision logs, MoMs, and dashboards that show ownership and next steps.

A strong implementation doesn’t avoid these challenges by accident. It avoids them through structure: a clear scope, a phased plan, and a governance model that keeps everyone aligned.

Now that we’ve covered where most teams slip, let’s look at how to do it right with a step-by-step, predictable implementation approach.

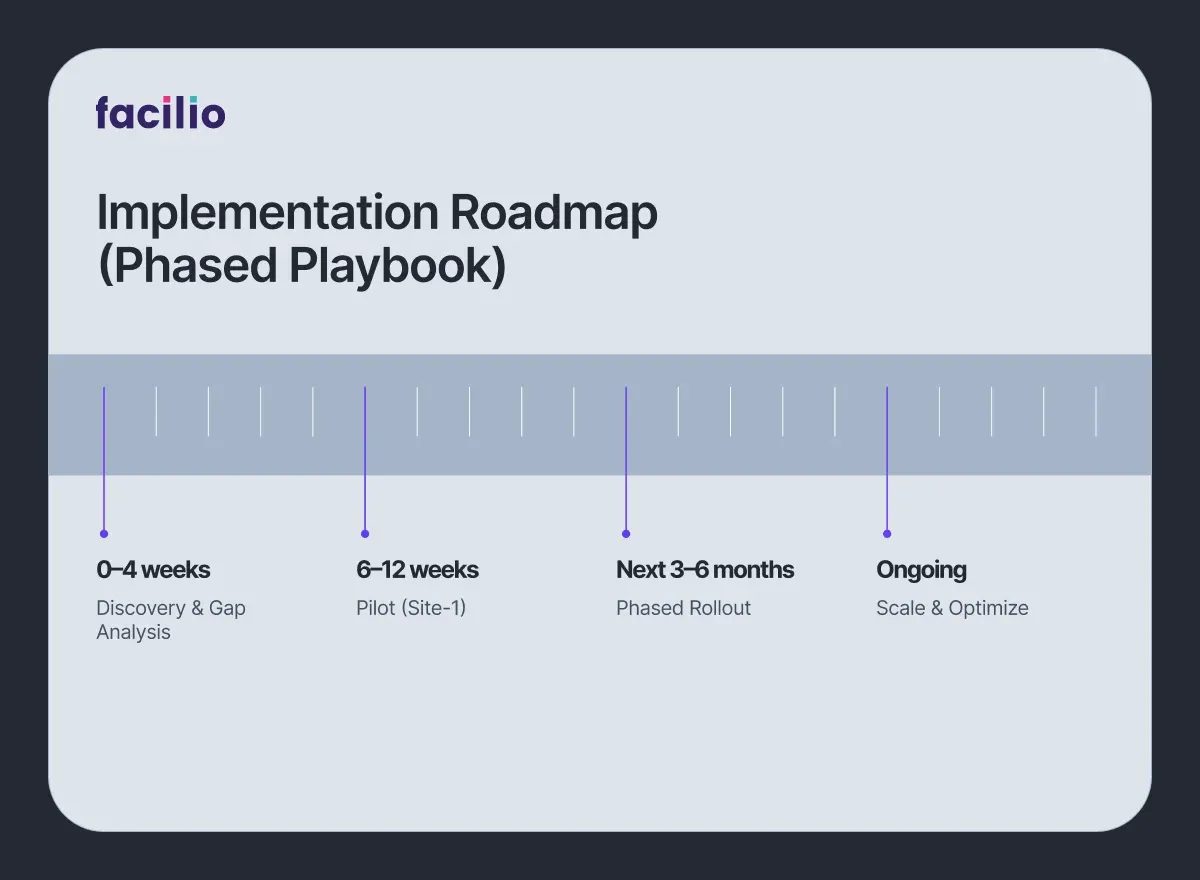

CMMS implementation roadmap in 2026: What modern teams need to succeed

CMMS implementation isn’t guesswork anymore.

With clearer workflows, better data practices, and faster deployment models, teams in 2026 need a roadmap that’s structured, predictable, and adoption-ready.

Here’s the version that actually works.

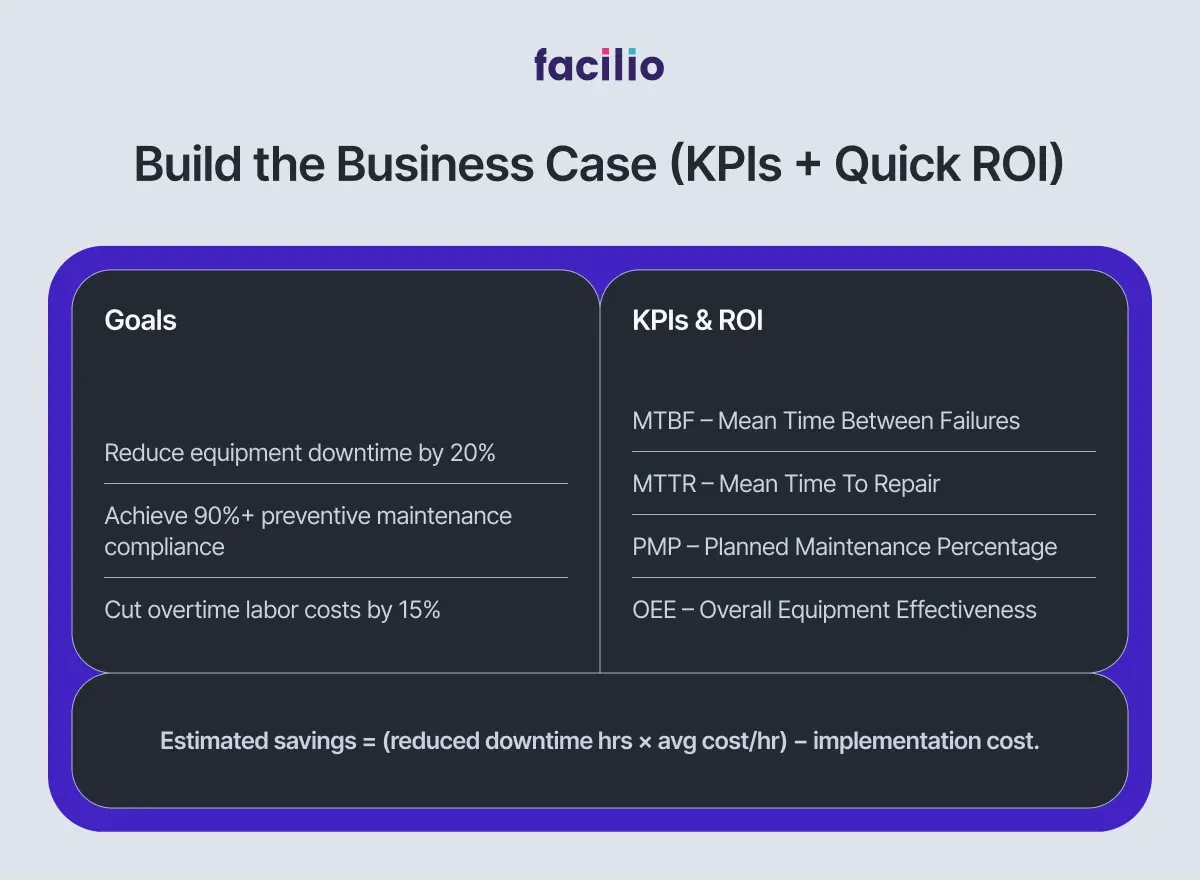

1. Build a business case that drives clarity and alignment

Every successful CMMS rollout starts with a grounded business case.

Before you even step into implementation, define the outcomes you want to achieve: reduced downtime, higher technician productivity, cleaner audits, better inventory control, or cost visibility.

This becomes the foundation for scope, timelines, and the KPIs that guide your entire project.

At this stage, teams should also outline the pre-Kick-Off expectations: project sponsors, implementation leads, cross-functional contributors, and baseline metrics. This creates alignment long before the first workshop begins.

2. Set up governance that keeps the project on track

Good intentions don’t keep implementations on schedule. Governance does.

This is where Facilio’s Kick-Off and BRD phases come into play.

During Kick-Off, teams finalize roles, responsibilities, communication channels, and the project cadence.

Through BRD workshops, business workflows are mapped in detail, dependencies are flagged early, and both teams commit to clear entry and exit criteria.

Governance isn’t a one-time setup — it’s a continuous discipline.

Many teams adopt a meeting rhythm that includes:

- Weekly progress and blocker reviews

- Monthly project reviews

- Quarterly executive check-ins

This ensures visibility at every layer and reduces delays caused by unclear ownership.

3. Map your maintenance reality and define what the future should look like

Before configuring any system, you need a solid understanding of how your maintenance operations work today.

Map existing workflows, asset hierarchies, approval paths, inventory processes, and technician routines.

Then define the “to-be” version — the streamlined workflows, automation opportunities, mobility requirements, and reporting needs that will shape your CMMS.

This step correlates directly with BRD sign-off in the engineering blueprint, ensuring your implementation team has the clarity needed to move confidently into configuration.

4. Build an implementation plan that teams can actually follow

Once your requirements are approved, it’s time to translate them into a structured rollout plan. This includes:

- Scope of the first release

- Prioritized workflows

- Integration requirements

- Timeline for configuration

- Responsibilities of each team

- Testing and acceptance criteria

This is where the engineering phases of Integration and Implementation align — with clear prerequisites, documented decisions, and well-defined checkpoints.

The goal is to prevent scope creep, maintain transparency, and ensure no step is skipped.

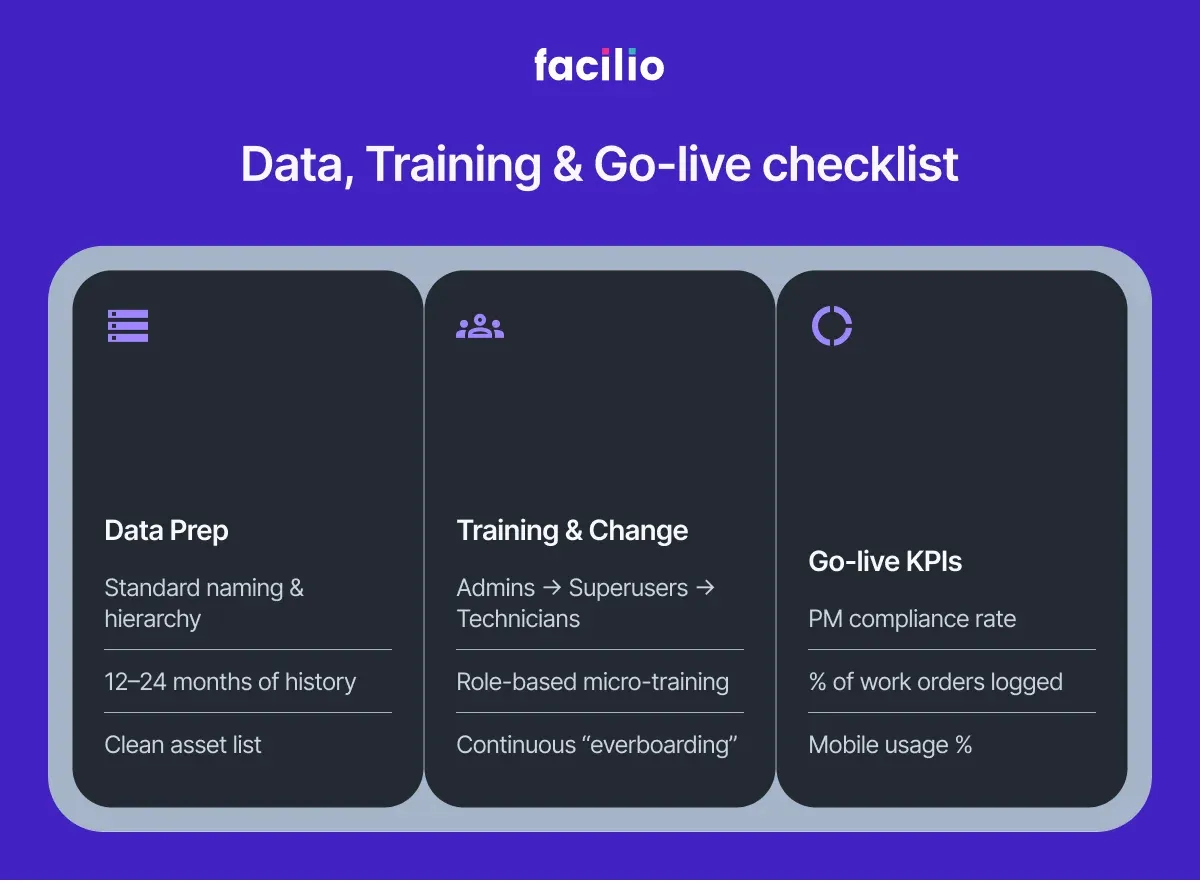

5. Prepare clean, structured data and plan integrations early

Data onboarding is often underestimated, yet it’s one of the most critical determinants of CMMS success.

During this phase, you’ll:

- Audit existing data sources

- Clean and standardize asset lists

- Validate naming conventions

- Map historical maintenance logs

- Prepare inventory and vendor data

- Identify CMMS integration touchpoints

This aligns directly with the engineering Data Onboarding Phase, which includes data sanitization, user provisioning, and validation cycles.

If integrations (ERP, BMS, sensors, or procurement tools) are required, they should be planned early so they don’t become last-minute blockers.

This includes systems beyond maintenance, such as a visitor management software, which relies on clean data and integrations to maintain accurate access logs and on-site visibility.

6. Train your teams and build a smooth change-management plan

Technology alone doesn’t change operations — people do.

Training and adoption need to run in parallel with implementation, not as an afterthought. This phase includes:

- Role-based training

- Hands-on sessions for technicians

- Admin and supervisor coaching

- UAT (User Acceptance Testing) cycles

- Clear communication on “what’s changing and why.”

This corresponds to the engineering blueprint’s Training & UAT Phase, ensuring every user is confident before go-live.

Strong change management reduces resistance, builds ownership, and ensures the system becomes a natural part of daily work.

7. Go live with confidence using clear exit criteria

Go-live should never feel rushed. The engineering team’s approach uses precise exit criteria:

- Functional testing complete

- Final data load validated

- Users provisioned and trained

- Critical defects resolved

- Sanity checks passed

Only once these are met should the system be deployed to all users.

This ensures your go-live is not just a switch-on moment but a controlled transition backed by preparation and alignment.

8. Monitor, optimize, and scale through structured hypercare

The first 60–90 days after go-live are crucial.

Facilio’s blueprint includes a Hypercare & Support Phase, where teams:

- Monitor performance and adoption

- Resolve early-stage defects quickly

- Track KPIs against the business case

- Fine-tune workflows and automations

- Introduce template libraries for multi-site scaling

Once stability is achieved, the program transitions to long-term governance and continuous improvement — ensuring your CMMS doesn’t become stale or underutilized.

Implement your CMMS software the right way with Facilio’s Connected CMMS

A successful CMMS implementation isn’t just about installing software. It’s about setting up the conditions for teams, data, and processes to work in sync. When organizations get the fundamentals right, the system becomes a true driver of operational improvement.

These fundamentals usually come down to:

- Clear scope and expectations

- Clean, validated data

- Structured rollout phases

- Practical, role-based training

- Steady, ongoing governance

Facilio’s implementation approach is intentionally built around these essentials. The checkpoint-led phases, BRD-driven clarity, predictable data onboarding steps, and guided UAT cycles remove guesswork and keep everyone aligned. And once the system goes live, structured hypercare ensures early issues don’t escalate and adoption stays strong.

If you’re planning a CMMS rollout in 2026, look for a framework that reduces uncertainty and builds momentum from day one.

The right CMMS software and implementation model won’t just help you launch faster. It will help your teams use the system confidently, measure impact early, and continue improving long after go-live.