Enterprise Asset Management (EAM) is a strategic approach for organisations to comprehensively control and optimise their physical assets like buildings, HVACs, elevators, vehicles, and plant machinery throughout their total lifecycle.

Unlike basic asset tracking, EAM leverages digital technology to automate, monitor, and optimise every aspect of asset interaction, from initial acquisition and compliance to maintenance and eventual retirement.

Top Benefits of Using EAM Software

Modern EAM platforms centralise asset information, streamline workflows, and enhance decision-making by integrating with core systems such as ERP, BMS, and IoT.

This enables robust cross-team collaboration and creates a trusted “single source of truth.”

Let's take a look at a few top benefits:

Maximised Asset Performance & Up-Time

Through real-time asset inventories and automated maintenance triggers, organisations using EAM can closely track asset health, reduce response times to service needs, and move towards proactive, preventive maintenance models. Many companies experience significant reductions in unplanned downtime and improved equipment effectiveness.

Cost Efficiency at Scale

EAM consolidates maintenance, expense tracking, and spare parts management into a single, unified system. This enables organisations to optimise resources, limit excess inventory, and schedule maintenance before costly failures occur, driving a longer useful life and higher ROI for mission-critical assets.

Operational Visibility & Compliance

Comprehensive dashboards and analytics give teams a clear view across work orders, asset performance, and compliance tasks, whether at one site or enterprise-wide. Automated compliance modules help ensure audit readiness, minimise risk, and simplify reporting for industry regulations.

Sustainability & ESG Alignment

By monitoring energy use and targeting asset inefficiencies, EAM makes it easier for organisations to achieve both financial and environmental goals.

Proactive repairs and upgrades can reduce overall energy consumption and emissions, directly contributing to sustainability and ESG objectives.

Key Features of Enterprise Asset Management Solutions

Unlocking the value of EAM means leveraging its core capabilities to boost efficiency and provide actionable insights. Here are the foundational features:

- Central Asset Registry: Unified asset profiles with lifecycle tracking, status, documentation, and location data.

- Automated & Intelligent Work Order Management: Automatically assign, prioritise, and escalate tasks based on asset condition, time, or usage data.

- Mobile-First Field Tools: Technicians receive instant notifications and can complete tasks onsite, minimising paperwork and delays.

- Predictive & Condition-Based Maintenance: Integrated IoT and analytics anticipate equipment failures and recommend early interventions.

- Inventory and Spare Parts Sync: Sync parts usage with work orders and scheduled maintenance to minimise stock-outs and over-supply.

- Integration Across Enterprise Ecosystem: Leading EAM platforms integrate with ERP, BMS, and IoT systems, supporting true alignment between facility operations and broader business strategies.

- Stakeholder-Specific Experience: Dashboards and workflows tailored for operations, IT, finance, and frontline teams ensure relevant visibility and accountability.

- The synchronization of parts usage with work orders, a key feature of modern EAM, effectively tells you what you need and when you need it.

But enterprise efficiency goes one step further: automating the actual sourcing, quoting, and purchasing processes themselves. Don't let stock-out minimization turn into time-consuming manual purchase orders.

To transform the data-driven need into automated action and streamline vendor management across your portfolio, you should use a CMMS procurement and billing automation software.

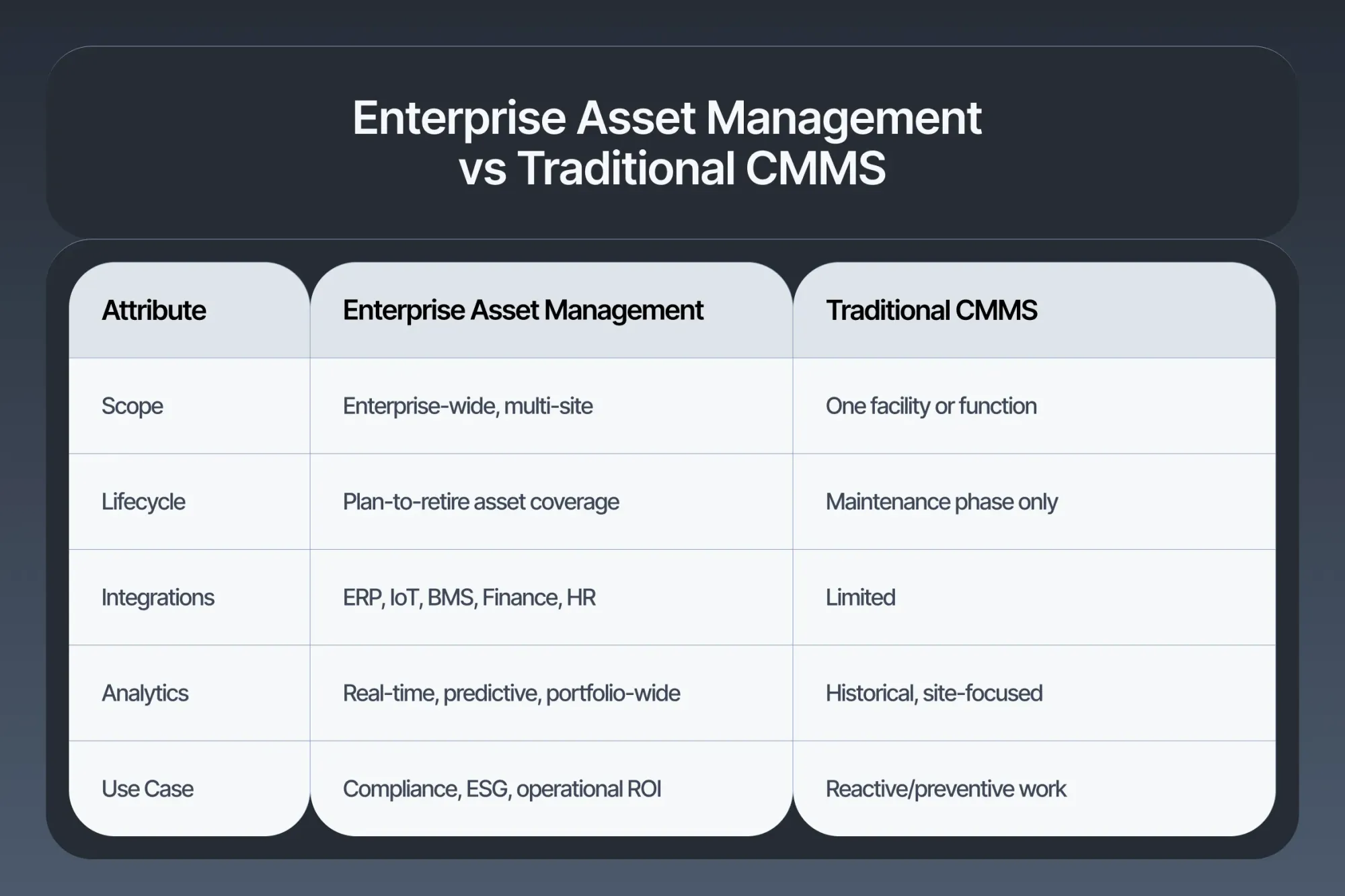

EAM vs. CMMS: What’s the Difference?

Choosing the right asset management solution starts with understanding the distinctions between EAM and CMMS tools.

EAM is designed for organisations that require scalability, sophisticated integration, and a more strategic approach to managing assets.

EAM is the natural evolution for organisations shifting from preventive maintenance to complete, strategic asset stewardship.

As operations grow or compliance demands increase, EAM offers the structure needed for scale, agility, and consistently higher performance.

How to Select the Best Enterprise Asset Management Software

Selecting an EAM platform is a pivotal decision that can significantly impact operational efficiency and the bottom line.

Use these guiding questions to evaluate your options:

- Does the platform support assets across multiple sites and business units?

- How well does it integrate with existing ERP, BMS, and IoT solutions?

- Is it customisable for your organisation’s unique workflows, compliance requirements, and reporting needs?

- Does the platform support game-changing features like QR code asset management and tracking ?

- Can technicians and field staff easily access and update information via mobile or the cloud?

- What proof of results, such as reduced downtime, cost savings, or improved compliance, can the vendor demonstrate from real-world implementations?

Industry leaders often share benchmarks such as rising preventive maintenance completion rates, reduced inventory costs, and overall improvements in equipment lifespan and reliability after EAM adoption.

EAM Trends & Future Outlook

Staying ahead in asset management means anticipating emerging trends and leveraging new technology.

Here are the leading innovations shaping the future of EAM:

- AI-Driven Intelligence: Machine learning and analytics reveal asset risks and cost-saving opportunities.

- Scalable Cloud Deployment: EAM systems can be rapidly deployed and scaled for organisations of any size.

- IoT-Powered Predictive Maintenance: Real-time sensor data enables proactive responses, driving towards zero-downtime operations.

- Sustainability Analytics: EAM tracks energy consumption, asset lifecycle, and helps measure progress on carbon reduction.

- Cybersecurity & Data Privacy: Modern EAM ensures secure workflows, regulatory compliance, and data integrity, even across large, distributed teams.

Why Consider a Next-Generation EAM Platform?

Today’s leading EAM platforms are designed for adaptability, automation, and integration, enabling organisations to move from reactive maintenance to proactive, strategic asset management.

To stay ahead of evolving industry trends and rising operational expectations, it’s crucial to invest in truly unified EAM solutions.

If you want to see how modern EAM can help future-proof your operations, consider exploring providers like Facilio, trusted by global enterprises for scalable, connected asset management.

FAQs

What’s the difference between EAM and financial asset management?

EAM focuses on maximising the value and performance of physical assets (e.g., buildings, machines), while financial asset management manages investment portfolios.

Do only large companies need EAM?

No, organisations of any size can benefit, especially as cloud-based EAM is now accessible and scalable for mid-sized businesses.

How quickly can you see ROI?

Many organisations report measurable results within 6–12 months, including fewer equipment breakdowns, lower maintenance costs, and improved asset value.