Best Asset Health Condition Monitoring Software Solutions

Picture this: unexpected equipment failures that disrupt your operations, costly downtime that drains your resources, and a never-ending cycle of maintenance issues.

Without proper asset condition monitoring software, you're left in the dark, unable to catch early warning signs of asset deterioration. This puts you at risk of incurring high repair and replacement costs. Beyond financial implications, neglecting asset condition monitoring poses grave safety hazards and regulatory violations.

Traditionally, companies have resorted to general-purpose predictive analytics applications that offer only partial operational asset visibility. These solutions rely on considerable technical resources and burden organizations with perpetual involvement in development, maintenance, and updates.

The interdependence between core enterprise systems and these general-purpose systems exacerbates the situation.

Also, the incompatibility of legacy asset monitoring software with modern IT infrastructure further amplifies operational costs and impedes maintenance advancements.

According to an industry survey, 88% of companies see aging technology as a significant challenge in their current maintenance processes, while 76% of companies find connecting modern assets and analyzing asset data to be a major obstacle.

However, a remedy to these complexities exists—modern asset condition monitoring software. Unlike legacy software, these cloud-based solutions use AI/ML and IoT operating systems that minimize expenses while maximizing efficiency.

By adopting such contemporary systems, facility managers can:

- Alleviate the strain on IT infrastructure, programming tools, and analytics services with full operational transparency.

- Convert these expenses into manageable operational costs.

- Redirect focus towards value-added endeavors, relinquishing the burden of IoT platform development and maintenance.

Before we jump into the ten best asset condition monitoring software we collected from across the web based on genuine user reviews, let's quickly recap what asset condition monitoring is and how software can help.

What is asset condition monitoring?

It involves monitoring various parameters, such as vibration, temperature, pressure, and electrical signals, to detect any deviations from normal operating conditions.

Asset condition monitoring aims to identify potential issues or failures early on, allowing O&M teams to take timely and preventive maintenance actions. This proactive approach enables you to minimize costs, improve operational efficiency, and maximize the reliability and availability of your assets.

Top asset condition monitoring software: Quick comparison

Top asset condition monitoring software in 2024

We rounded up some of the top go-to software for asset tracking monitoring in 2024. In our research, we uncovered their best features and took a look at verified customer feedback for each one to provide a holistic view of the strengths and weaknesses of our selection.

- Facilio

- SAP Asset Intelligence Suite

- Oracle Primavera asset management

- Predix

- ThingWorx

- Moxa

- Emerson AMS

- Honeywell Forege asset performance suite

- Siemens MindSphere

- eMaint

Facilio

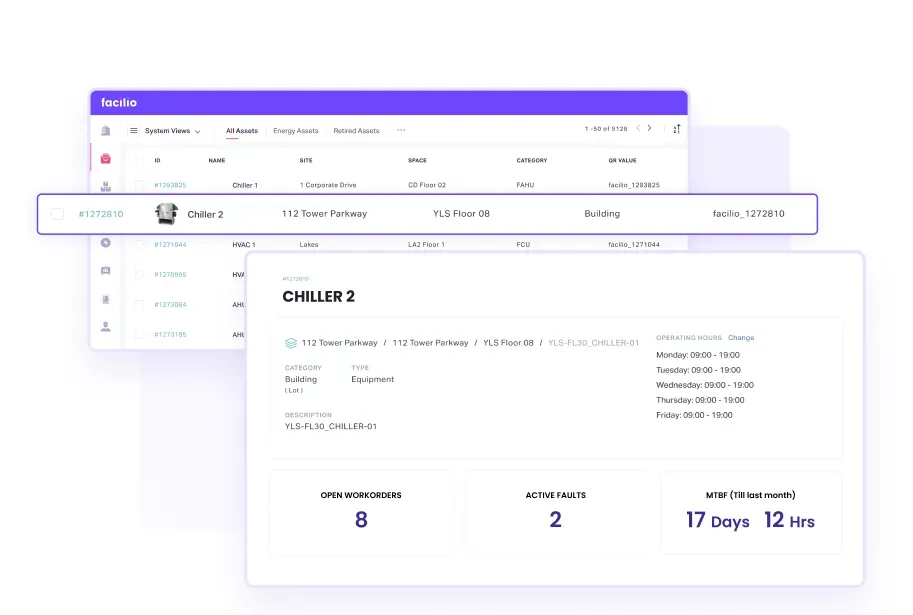

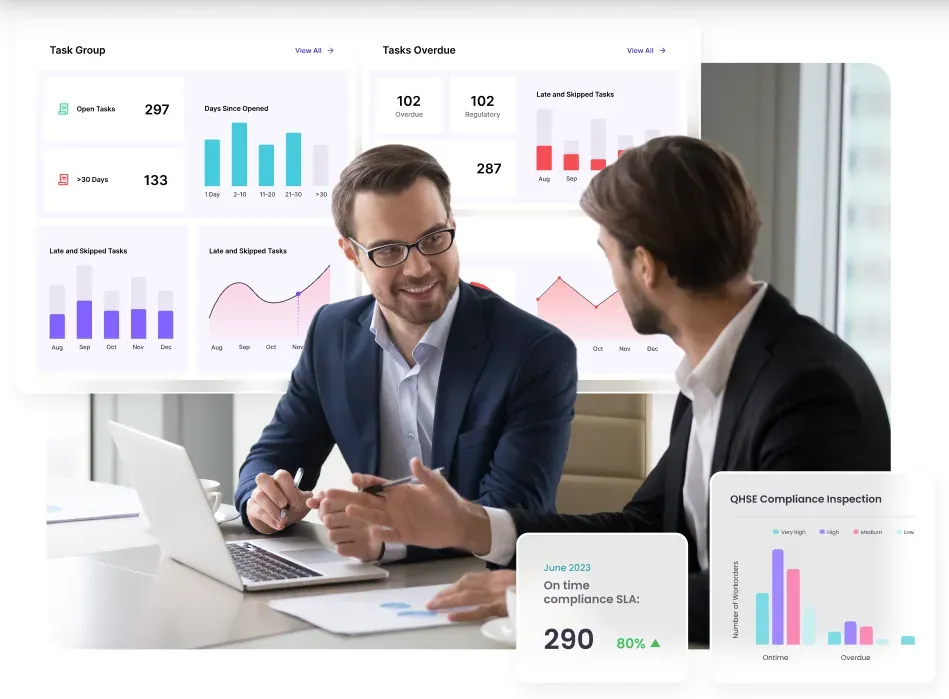

With Facilio's asset management software, you can unleash the power of predictive maintenance, take timely data-driven decisions, and streamline asset monitoring and management to maximize operational efficiency.

Facilio’s cloud-based software brings it all together, allowing you to monitor your assets’ movement and real-time performance without having to toggle between systems. You can ditch siloed data and spreadsheets, and instead, see a real-time, 360-degree view of all your facilities’ health.

Its intuitive interface provides dynamic dashboards displaying equipment performance, allowing you to identify trends and potential issues before they snowball into costly downtime.

Facilio’s software empowers facility managers with a future-proof approach to asset management that goes beyond monitoring. It integrates advanced features, including real-time monitoring, AI-powered predictive analytics, and energy management capabilities, into a cohesive module that takes your asset management from reactive to proactive.

Facilio key features

Visual performance metrics of asset lifecycle:

Utilize intuitive visualizations and comparison benchmarks to monitor the health and performance metrics (like MTTR and MTBF) of high-value assets. Identify deviations swiftly to minimize downtime and implement corrective measures promptly.

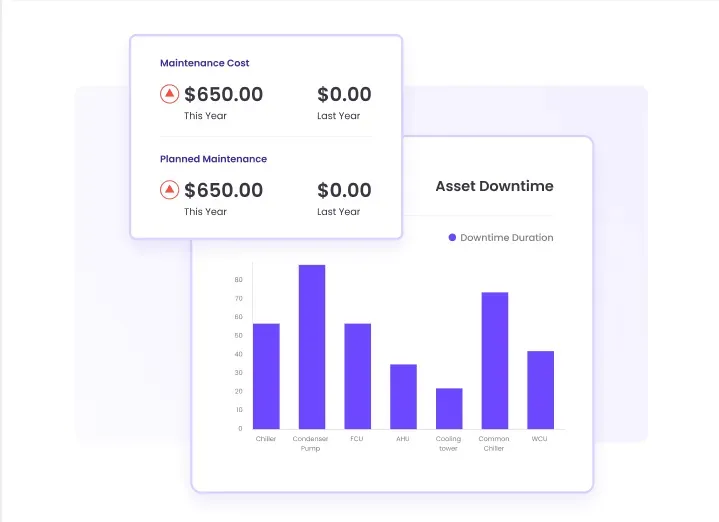

Asset depreciation analysis:

Conduct a thorough analysis to understand asset depreciation trends, downtime statistics, and factors contributing to value erosion over time. With Facilio, you can also automate maintenance management, multi-stage approvals, and alarms for assets and assign workforce to work orders accordingly.

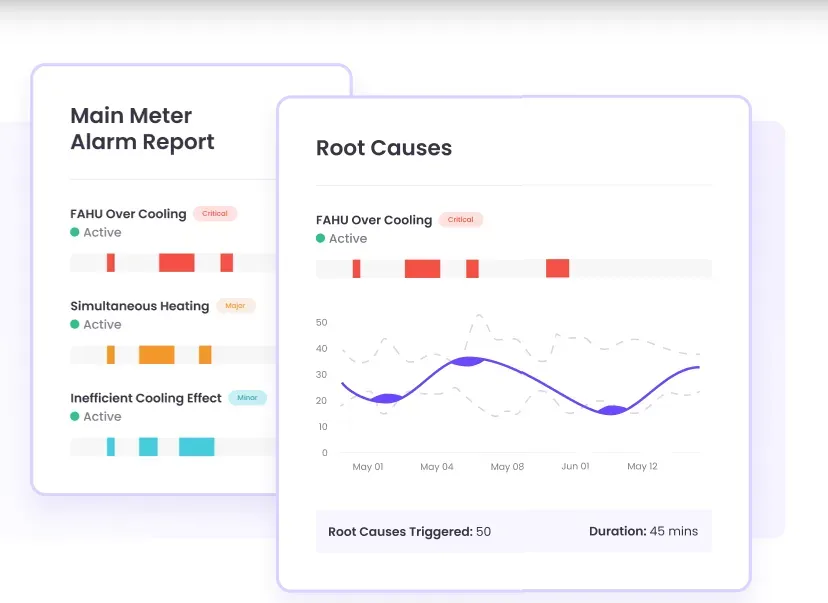

IoT monitoring and anomaly prediction:

Predict potential asset breakdown using alarm triggers connected to preset condition criteria for any deviation from standard operations. You can also analyze the root causes of asset faults to prevent failures.

Monitor audit and compliance management for assets:

Effectively adhere to regulations by putting compliance on autopilot. This ensures timely replacements and renewals for aging assets, effectively mitigating the risk of safety compliance violations and potential penalties.

Case study: Facilio optimizes British Land’s asset portfolio

British Land, a leading UK-based property development and investment company, aimed to transform their properties into net-zero, sustainable, and smart buildings.

Challenge:

Despite having access to consumption data, lacking contextual information hindered their ability to gain insights into optimizing assets for cost and energy savings.

The absence of a robust Fault Detection and Diagnostics (FDD) system exacerbated these challenges, leading to inefficiencies and increased operational costs.

Solution:

Leveraging advanced asset condition monitoring capabilities, Facilio integrated lighting sensors and occupancy sensors across British Land's facilities.

Using real-time data from these sensors, Facilio intelligently controlled lighting, air-conditioning, projectors, and other equipment, turning them off when not in use to minimize energy wastage.

Facilio’s FDD engine also provided contextual error reports, identified the root cause of issues or abnormalities, and suggested remedial actions for assets based on real-time data and historical patterns.

Impact

- Over 300,000 minutes of air conditioning operations per month were optimized.

- Facilio achieved a remarkable 50% year-on-year reduction in heating and cooling expenses.

What users think about Facilio:

Anirudh N., who works in real estate and has been using Facilio every day for around six months now, says it might be the first predictive FM software out there!

In his words:

“Overall, we've had a really smooth experience. The notifications and email flow have dropped considerably, which has eased a lot of my colleagues' and my time's burden. You can create workflows that help you detect equipment problems before they happen, which has helped us save huge amounts of energy.”

Facilio has a 4/5 star rating on GetApp

Keep your assets performing at the peak throughout their lifecycle

SAP Asset Intelligence Suite

This software platform helps monitor and manage a wide range of assets, including equipment, facilities, and vehicles. It provides real-time data on asset health and performance and predictive analytics to help identify potential problems before they occur.

SAP Asset Intelligent Suite key features

- The software collects equipment data in the cloud and tracks it to provide comprehensive asset management.

- SAP EAM offers tight integration with other modules of the SAP ERP suite.

- SQL features in SAP enable linkage with other databases for more interoperability.

What users like

“This is another unique and one of the most advanced EAM software with tailored workflows. This software helps streamline our assets more productively and maximize our resources output.” - Devendra S.

What users don’t like

“It is very cumbersome to use, and the user interface and experience are not modern.” - Nnamdi E.

Oracle Primavera Asset Management

Oracle’s Primavera is an easy-to-use solution for managing various types of assets, such as equipment, vehicles, and facilities. It’s available both as a cloud-based and on-premise solution and helps with maintenance management, facility condition assessment, lease management, and more.

Oracle Primavera's key features

- Oracle Primavera Unifier offers cloud and on-premise functionalities, providing extra flexibility in data analytics preparation.

- Oracle has cost control capabilities and enables thorough earned value management analysis.

- The software offers connectivity with ERP, CMMS, CRP, and other enterprise solutions.

What users like

“The platform is loaded with excellent and functional tools, in which the user can easily manage multiple assets with the platform.” - Ellie J.

What users don’t like

“Some features are missing in unifier like alerts, reminders and escalation.” - Verified User.

Predix

Predix is a cloud-based asset condition monitoring software that uses machine learning and artificial intelligence to predict when assets will fail. It can also track asset performance and identify areas for improvement.

Predix key features

- Predix integrates diverse data sources and applies advanced analytics for actionable insights.

- The software leverages Amazon Web Services (AWS) and essential IoT functions to provide a unified application framework.

- Customers benefit from a one-time investment in secure and scalable IoT software infrastructure.

What users like

“The device handling power, the device management functionality. The overall flow of operation is easy to understand, and anyone can use it.” - Vishal S.

What users don’t like

“Support for onsite devices deployment could be improved.” - Dnyaneshwar G.

ThingWorx

ThingWorx is a platform for the Industrial Internet of Things (IIoT) that collects, stores, and analyzes data from various sources, including sensors, machines, and people. This data can monitor asset conditions and predict when maintenance is needed.

ThingWorx key features

- It offers ready-to-deploy asset monitoring and utilization (AMU) functionality that utilizes existing systems and data for real-time monitoring.

- Its connectivity spans various devices with an always-on protocol, ensuring seamless integration.

- The platform facilitates easy deployment and development and streamlined data aggregation from production controllers.

What users like

“I have mostly used ThingWorx for remote monitoring/service portals, and in that context, it is a very robust portal to connect your IoT devices to a cloud platform.” -Unnikrishnan P.

What users don’t like

“The learning curve can be quite high for someone that doesn't know the language and is new to a software like this.” - Jonathan.

Moxa

Moxa offers a suite of asset condition monitoring solutions tailored for diverse assets, from machinery and vehicles to buildings. Through advanced sensor technologies, these solutions capture and analyze real-time data, providing invaluable insights into asset health and performance optimization.

Moxa key features

- Its integration with SCADA (Supervisory Control and Data Acquisition) and MES (Manufacturing Execution System) systems enables comprehensive asset condition monitoring.

- Moxa's protocol converters offer robust and reliable communication capabilities.

What users like

“Compact size and helpful tool in automation and networking” - Verified User.

What users don’t like

“The products of Moxa are more expensive compared to other competition” - Hafeez A.

Emerson AMS

Emerson AMS is a software platform for monitoring and managing various assets, including pumps, motors, and valves. It provides real-time data on asset health and performance and predictive analytics to preemptively flag potential issues, mitigating risks proactively.

Emerson AMS's key features

- Emerson's condition monitoring service enhances your existing in-house program with on-demand analysis.

- Emerson's AMS 6500 ATG, with AMS machine works software, ensures robust protection and predictive monitoring for critical assets.

What users like

“Very easy to use and also fast and effective.” -Thomas H.

What users don’t like

“Has issues sometimes processing certain cards.” - Thomas H.

Honeywell Forge Asset Performance Suite

Honeywell uses predictive analytics to monitor and manage asset health, cybersecurity, integrity, energy, and efficiency performance all in one outcome-based software solution.

Honeywell key features

- It uses closed-loop process strategies that utilize hybrid AI/ML models and integrated workflow to monitor asset conditions and expedite process recovery.

- It has four modules: health, predict, optimize, and excellence, all aimed at overall asset operational optimization.

What users like

“The reports are very useful - well-constructed UI - good error reporting - reliable software” - Verified User.

What users don’t like

“Sometimes the features are down for a few days, and I worry that the overall data will be skewed.” - Jess C.

Siemens MindSphere

This is an open, cloud-based platform for collecting, storing, and analyzing data from various sources, including sensors, machines, and people. Through the Asset Manager configuration, users can monitor pertinent data sources crucial for evaluating machine performance.

Siemens MindSphere's key features

- The data science workbench module in MindSphere provides access to Zeppelin notebooks for model authoring.

- MindSphere enables modeling of industrial process structures and tracking of data sources relevant to asset performance.

- The software’s predictive learning workspace offers tools to explore and analyze big data without extra scripting.

What users like

“Supports multiple OT protocols and mature gateway devices for industrial connectivity.” - Verified User.

What users don’t like

“Limitations in third-party integrations and lack of a dedicated interface for quick information access by the production team’s potential restrictions on customization.” - Verified User.

eMaint

eMaint offers a CMMS platform with advanced EAM and asset performance management features. It serves various industries, including food and beverage, automotive, warehouse, and healthcare. It provides condition monitoring for predicting equipment failures and recommends maintenance actions based on AI analysis.

eMaint key features

- With a wide range of modules, eMaint effectively handles tasks such as asset tracking, inventory management, purchasing, and work orders.

- The software has interactive maps that simplify usage for users at all levels of computer proficiency.

What users like

“The eMaint system allows me to be able to access assets from other locations, repairs, parts inventory and most importantly, preventative maintenance schedules.” -Gerry D.

What users don’t like

“There is a lack of documentation of the more advanced configuration features that can be useful to system administrators and consultants.” - Felix W.

What does an asset condition monitoring software do?

Asset condition monitoring software collects data from sensors attached to assets such as machines, vehicles, and buildings. This data can include vibration, temperature, and pressure.

The software then analyzes the asset’s performance data to identify potential problems. If a problem is detected, the software can alert maintenance personnel so that they can take corrective action before the asset fails.

There are two main types of asset condition monitoring software:

- Real-time, IoT-based monitoring: Collects data from sensors in real-time, allowing maintenance personnel to address problems immediately as they occur.

- Scheduled monitoring: Collects data from sensors at regular intervals, which is less expensive than online monitoring but may be less effective at early problem detection.

Asset condition monitoring software also plays a significant role in predictive maintenance practices by leveraging advanced analytics to manage asset health and performance proactively. Here’s how:

- Predictive capabilities: By continuously monitoring asset conditions, the software can predict potential breakdowns or failures before they occur.

- Historical data analysis: The software analyzes historical data to establish baseline patterns and condition thresholds for healthy equipment behavior.

- Model building: It develops models for individual assets based on specific health indicators such as:

- Vibration

- Pressure

- Temperature

- Load

- Cycles

- Real-time monitoring: These models are deployed in real-time, allowing the software to compare expected behavior with actual machine performance.

- Alert system: It sends alerts and recommends corrective actions based on the variables responsible for the deviations.

Recommended read: Best predictive maintenance software in 2024

Benefits of asset condition monitoring software

1. Improve worker safety and health compliance

Sensors detect early signs of developing faults, enabling preemptive action to ensure worker safety.

Monitoring parameters such as vibration, temperature, and pressure helps prevent issues like fastener disassembly, debris generation, and the unintentional release of toxic substances.

2. Reduce unplanned downtime

Asset condition monitoring solutions offer precise evaluations of equipment performance, simplifying the identification of components requiring replacement. By reducing equipment repairs’ time-to-resolution, your company gains valuable uptime, lowers labor expenses, and enhances its assets' return on investment (ROI).

3. Optimize maintenance scheduling

Instead of relying on fixed maintenance intervals, asset condition monitoring allows maintenance to be performed based on the actual real-time condition of the equipment. This minimizes unnecessary maintenance and prolongs asset lifespan by avoiding over-maintenance.

4. Reduce damage risk to assets in transit

Security alerts, incorporating container identification, can effectively manage assets in transit through real-time notifications. Asset condition monitoring software generates necessary chain-of-custody documents, effectively reducing the likelihood of damage, theft, or loss.

5. Data-driven decision-making for asset management

Analyzes vast amounts of data in real-time and provides detailed metrics into assets' current performance and health status. This data-driven methodology gives facility managers actionable insights to make informed decisions, refine operational strategies, and strategically plan future capital investments.

Considerations for selecting asset condition monitoring software

Here are five key features to prioritize when selecting an asset monitoring software for facilities management companies:

1. A centralized repository:

Select software that consolidates all asset data onto a single, easily accessible platform for operators, facility managers, and maintenance teams. This integration enhances visibility and streamlines communication and collaboration, avoiding the complications of siloed data in disparate systems.

2. Fully integrated IoT sensors:

Ensure the software integrates seamlessly with a wide range of IoT sensors for comprehensive monitoring across your asset portfolio. IoT sensors provide real-time data on asset health based on parameters such as temperature, vibration, and pressure.

3. Architecture that handles massive data volumes:

Choose software with an architecture that can expand with your asset portfolio and data sources without compromising performance. This ensures uninterrupted monitoring and future-proofing against growing data requirements.

4. Quick implementation and adoption:

Opt for a solution with a streamlined implementation process, including pre-configured templates and intuitive setups, to accelerate time-to-value and facilitate rapid adoption by end-users.

5. Advanced pattern recognition in large data sets:

A software equipped with advanced analytics can sift through vast data sets, identifying patterns indicative of potential failures or inefficiencies. It should also leverage machine learning algorithms that predict future maintenance needs based on historical data patterns.

Tips for evaluating the right asset condition monitoring software for your facilities

Evaluating the right asset condition monitoring software for your use cases is no walk in the park. To add to the already complex challenge, the sea of vendors leaves you spoilt for choice.

To navigate this and pick a software that will tend to your needs today and in the future, keep these pointers in mind:

Consider your industry and asset types: Not all asset condition monitoring software is created equal. Some solutions are better suited for specific industries or asset types. For example, software for oil and gas companies will likely have different features than software for manufacturing companies.

Identify your needs: What do you hope to achieve with asset condition monitoring? Do you want to reduce downtime, improve efficiency, or extend the life cycle of your assets? Once you know your goals, you can start narrowing down your options.

Evaluate features and functionality: Once you've identified a few potential solutions, it's time to start evaluating their features and functionality. Consider the following:

- Data collection and analysis: How does the software collect data from your assets? How does it analyze that data to identify potential problems?

- Reporting and alerts: How does the software generate reports? How does it send alerts when there is a potential problem?

- Integration with other systems: Does the software integrate with other systems, such as your ERP or CRM system?

Facilio is an industry favorite for end-to-end asset lifecycle management, and we'd be happy to show you why over a free demo. Click on the button below to get started!

FAQ

What sensors are typically used with asset condition monitoring software?

Vibration sensors are the most commonly used for monitoring assets in a facility. Others include temperature, pressure, and acoustic sensors for more comprehensive data collection.

How does asset condition monitoring software help in reducing downtime?

Asset condition monitoring software enables proactive maintenance interventions by continuously monitoring asset health and detecting anomalies early, ultimately minimizing unplanned downtime.

How does asset condition monitoring software contribute to predictive maintenance strategies?

Asset condition monitoring software predicts equipment failures through the analysis of sensor data. This allows for scheduling maintenance activities before issues escalate, optimizing maintenance resources and extending asset lifespan.

More from Facilio