Discover reliability-centered maintenance (RCM), a framework to boost uptime, cut costs, and improve safety. Learn its principles, 7-step process, benefits, challenges, and how to implement an effective RCM program.

What is reliability-centered maintenance (RCM)?

Reliability centered maintenance, often shortened to RCM, is a decision-making framework that helps organizations determine the most effective maintenance strategy for each asset.

Instead of applying a one-size-fits-all preventive schedule, RCM focuses on analyzing how equipment can fail, what the consequences of those failures are, and how best to prevent or mitigate them. This makes RCM reliability a cornerstone of modern asset management.

Today, RCM is less about following rules and more about adopting a mindset—one that prioritizes reliability, safety, and cost-efficiency over quick fixes.

Next, let’s look at the core principles that guide this approach.

Principles of reliability-centered maintenance

RCM is built on a few simple but powerful principles. These guide how teams decide what kind of maintenance an asset really needs:

- Function first: Start by defining what the asset is supposed to do. A pump isn’t just a piece of equipment; it’s there to deliver a set flow at a certain pressure.

- Failure focus: Identify how the asset can fail and what causes those failures.

- Consequence-driven: Not every failure is equally serious. RCM looks at the impact—on safety, operations, and cost—before deciding how to act.

- Prevent where it matters: Use preventive or predictive maintenance for critical failures, and allow non-critical failures to run to breakdown if that’s more cost-effective.

- Continuous improvement: RCM isn’t a one-time activity. It evolves as new data, technology, and insights become available.

These principles encourage organizations to move away from “fix everything on schedule” and toward a more balanced, proactive maintenance culture.

Now that we’ve covered the guiding ideas, let’s dive into how RCM works in practice—the step-by-step process known as RCM analysis.

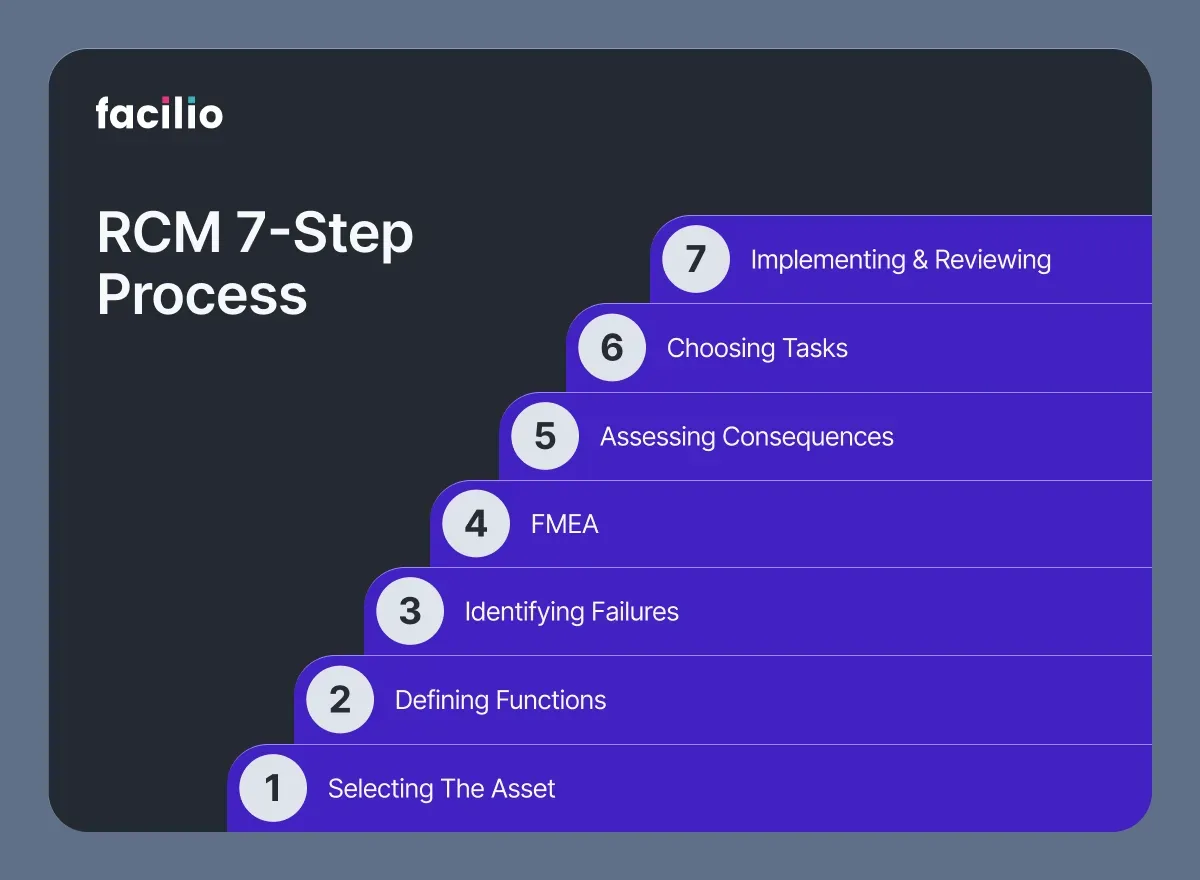

The RCM process: A comprehensive 7-step guide for effective implementation

Without a doubt, RCM is a powerful strategy that helps organizations achieve optimal performance, minimize downtime, and reduce maintenance costs. However, implementing RCM effectively requires a well-defined, step-by-step approach.

So, we have devised an expert-driven, actionable framework for integrating RCM into your maintenance strategy.

Step 1: Identify critical assets for RCM Analysis

The first step in implementing RCM is to determine which equipment and systems warrant analysis. This process starts with a criticality analysis to assess the potential impact of equipment failure on operations, safety, and financial outcomes.

Key considerations:

- Assess the cost of failure and its effect on production, safety, or the environment.

- Prioritize high-value assets or those critical to the facility’s core functions.

- Consider historical maintenance costs and the frequency of failure.

This step ensures that RCM focuses on what matters most.

Step 2: Define system boundaries and functions

Once you’ve selected the assets, the next step is to define the systems that house these critical components. This includes understanding the role of the asset within the larger system, its inputs, outputs, and overall function.

For example, a conveyor system used to transport goods:

- Inputs: Goods and mechanical energy (powered by motors).

- Outputs: Finished products delivered to the next stage of production.

- The function of the system is to transfer goods efficiently, which must be assessed in relation to its parts.

By setting clear boundaries, you ensure all components affecting performance are considered.

Step 3: Identify failure modes

The third step involves systematically identifying all the potential ways each system can fail to meet its desired function. This requires collaboration among maintenance teams, operators, and engineers to ensure every possible failure scenario is explored.

Examples of failure modes:

- The conveyor belt could fail to carry goods due to slippage or excessive wear.

- A motor could experience overheating, causing it to shut down unexpectedly.

Identifying failure modes is essential to understanding what could go wrong and why.

Step 4: Root cause analysis

After failure modes are identified, the next step is to understand the underlying causes. This is where deep expertise is required to differentiate between symptoms and root causes.

Methods for root cause analysis:

- Conduct fault diagnostics with maintenance technicians.

- Review historical maintenance logs for recurring issues.

- Involve equipment experts to inspect designs or material choices that could be contributing to failure.

Example:

- A failed bearing might be traced to poor lubrication practices, which could be rectified by introducing a better lubrication schedule.

Accurately diagnosing root causes ensures that corrective actions address the true problem rather than just the symptoms.

Step 5: Evaluate the consequences of failure

In this step, each failure mode is evaluated for its potential impact on operations, safety, and finances. This is a critical phase where the severity and probability of failure must be assessed.

Techniques used for evaluation:

- FMEA (Failure Modes and Effects Analysis) to quantify the risk of failure.

- FTA (Fault Tree Analysis) to identify potential fault paths.

- RBI (Risk-Based Inspection) for prioritizing critical failure modes based on risk.

Example:

- The failure of a pressure relief valve could lead to a catastrophic explosion, whereas a vibration in a pump might result in minor operational disruptions. These differences must be considered when determining the priority of corrective actions.

Evaluating failure consequences ensures that resources are focused on preventing the most severe risks.

Step 6: Select the appropriate maintenance strategy

With failure modes prioritized, the next step is to choose the most effective maintenance strategy. The chosen tactics must be both technically feasible and economically viable for each identified failure mode.

Common strategies include:

- Condition-Based Maintenance (CBM) uses monitoring tools to detect early signs of failure.

- Time-Based Preventive Maintenance (PM), that schedules maintenance tasks at regular intervals.

- Run-to-Failure, where the asset continues operating until it fails, but is replaced quickly.

Example:

- For a motor, condition-based monitoring might detect increased vibration or temperature, allowing for corrective maintenance before a complete failure occurs.

- For less critical assets, a run-to-failure approach may be more cost-effective.

Selecting the right strategy ensures you apply the most efficient and effective maintenance methods.

Step 7: Implement and continuously review maintenance strategies

The final step in the RCM process is to implement the selected maintenance strategies and ensure they are consistently carried out.

Regular performance reviews and feedback loops are essential for gauging effectiveness and making adjustments as needed.

Continuous review activities:

- Track key performance indicators (KPIs) such as downtime, mean time between failures (MTBF), and maintenance costs.

- Conduct post-maintenance reviews to determine if maintenance actions were successful.

- Implement scheduled audits to ensure strategies remain relevant and effective.

Example:

- After implementing a new preventive maintenance schedule for a cooling fan, the team monitors the fan's performance over time to verify the reduction in failures and operational disruptions.

This step is crucial for refining RCM practices and ensuring they evolve in line with the organization's needs.

Ready to roll out an RCM maintenance program?

Facilio makes RCM implementation practical and scalable - learn how with a demo

Schedule a DemoDifference between RCM and other types of maintenance

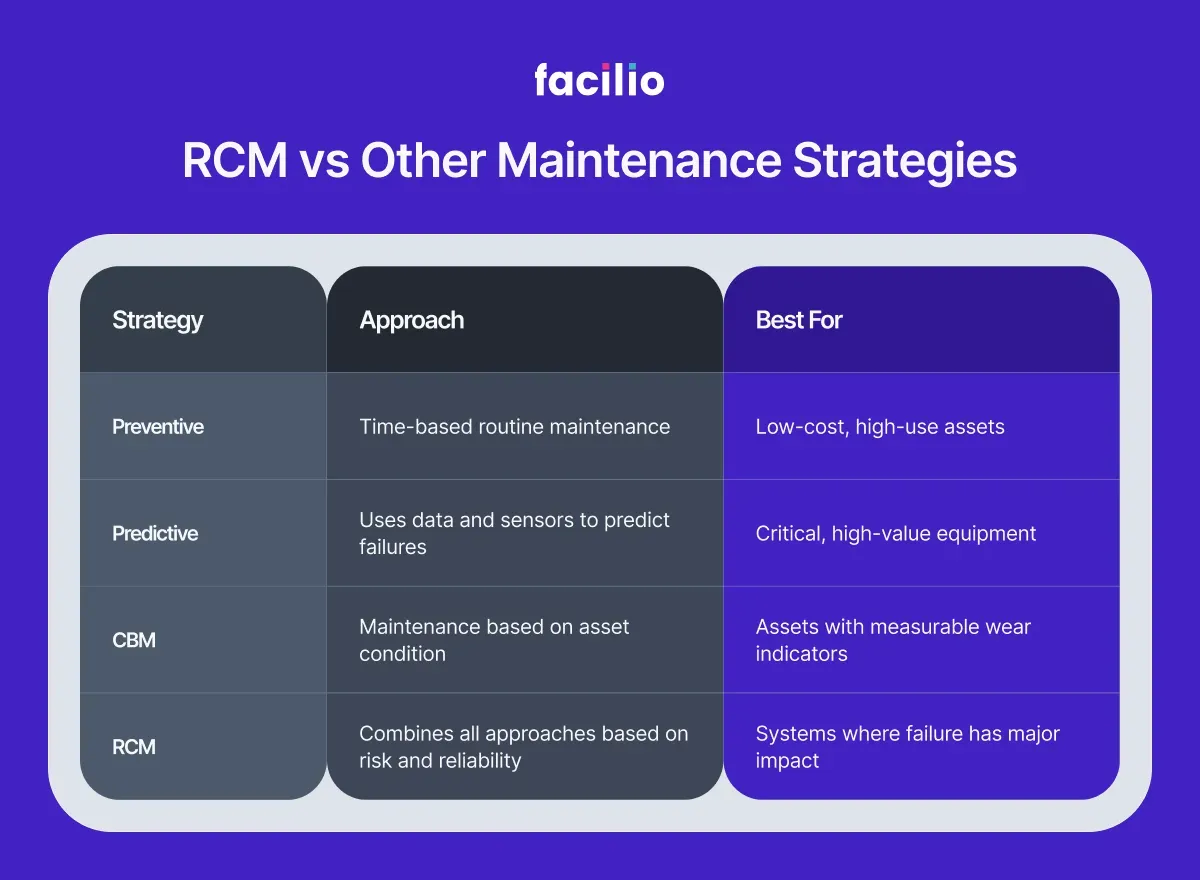

Reliability-centered maintenance doesn’t replace other strategies; rather, it helps decide which one to use and when.

That’s why you’ll often hear RCM described as the “decision framework” behind preventive, predictive, and condition-based maintenance (CBM).

Here’s how RCM in maintenance fits alongside other approaches:

In short, there are several maintenance strategies, but each works differently. Here’s how they compare with reliability-centered maintenance (RCM):

- Preventive maintenance is scheduled at a fixed time or usage intervals. Helps avoid common failures but can lead to unnecessary work and higher costs.

- Predictive maintenance uses sensors and data to spot early signs of failure. Reduces downtime but requires investment in technology and skilled analysis.

- Condition-based maintenance is done only when an asset’s condition (vibration, temperature, oil quality) shows signs of wear. Efficient, but can be complex to monitor.

- In run-to-failure maintenance, assets are allowed to run until they break, then repaired or replaced. Works for non-critical equipment but risky for essential systems.

- Reliability-centered maintenance (RCM) is a structured framework that combines all of the above. It analyzes each asset and assigns the most effective strategy—preventive, predictive, CBM, or run-to-failure—based on risk and cost.

Suggested reads:

How to measure asset reliability with a bathtub curve?

A Quick Guide to Avoid Getting Pencil Whipped!

Reliability centered maintenance: What are the benefits and challenges?

Like any strategy, reliability centered maintenance comes with both advantages and hurdles. Understanding both sides helps teams set realistic expectations before rolling it out.

Benefits of RCM

- Higher uptime: By focusing on critical failures and preventing them, RCM reduces unplanned downtime and keeps operations running smoothly.

- Better cost control: Instead of spending money on unnecessary maintenance, RCM directs resources where they’ll have the biggest impact.

- Improved safety: By identifying and managing high-risk failures, RCM lowers the chance of accidents and compliance breaches.

- Stronger compliance: Many industries (aviation, oil & gas, healthcare) follow strict safety and reliability standards. RCM helps organizations meet these requirements with structured documentation.

Challenges of RCM

- Complexity: The RCM process requires detailed analysis, data collection, and cross-team collaboration. This can feel overwhelming at first.

- Upfront investment: Building an RCM program takes time, money, and often new technology. While it pays off long-term, the initial cost can be high.

- Training needs: Teams must be trained to think differently—shifting from calendar-based tasks to risk-based decision-making isn’t always easy.

When done right, the benefits of RCM far outweigh the challenges. The key is to start small—focus on the most critical assets first, prove the value, and then expand.

Suggested read: How to perform Facilities Condition Assessment?

Managing RCM manually is tough.

See how Facilio’s Connected CMMS simplifies the entire process with a 1-1 live demo

Schedule a DemoHow different industries benefit from RCM

Reliability centered maintenance has its roots in aviation, but its real value shines in industries where asset uptime directly affects people, safety, and operating costs.

Facility management and asset-heavy sectors are seeing some of the biggest gains from RCM. Here’s how various industries actually benefit from RCM.

Why is RCM the foundation of reliable operations?

Reliability-centered maintenance is more than just another maintenance strategy; it’s a mindset shift. By focusing on functions, failures, and consequences, RCM ensures that teams spend their time and resources where it matters most. The result is fewer breakdowns, safer operations, lower costs, and assets that deliver value over the long run.

But RCM works best when it’s backed by the right tools.

Without a connected platform, the analysis can feel overwhelming and hard to sustain. That’s exactly where Facilio's Connected CMMS helps.

- How Facilio helps – Makes RCM practical and scalable by:Mapping functions and failuresAutomating maintenance schedulingTracking results and refining tasks with real-time data

The outcome – RCM principles move from theory to daily practice, building reliability into the core of operations.

If you’re looking to make reliability a foundation of your maintenance strategy, an RCM-driven approach powered by Facilio can get you there—faster, smarter, and with measurable results.