What is MRO in facility management?

MRO stands for Maintenance, Repair, and Operations.

In simple terms, it refers to all the activities, tools, and supplies needed to keep an organization’s assets and facilities running smoothly.

While it may sound like industry jargon, MRO is part of everyday business, whether it’s routine maintenance to keep HVAC systems efficient, repairing faulty equipment, or stocking essential safety gear for employees.

In the context of facility management, MRO takes on an even bigger role.

It’s not just about tightening bolts or replacing filters; rather, it’s about keeping entire buildings and systems reliable, safe, and cost-efficient.

A single missed repair or an empty storage shelf can turn into downtime, higher expenses, or even safety risks.

Here’s what each part of MRO includes:

- Maintenance – regular upkeep, like servicing an HVAC system or doing safety inspections.

- Repair – fixing or replacing parts when equipment fails, whether that’s a motor, a pump, or a lighting fixture.

- Operations – the everyday supplies that keep things moving, from cleaning materials and safety gear to basic consumables.

So when someone asks, “What does MRO stand for?” or searches for a clear MRO definition, the answer is simple: it’s the work and resources that keep facilities functioning.

For facility managers, it’s a cornerstone of keeping costs under control, avoiding unplanned downtime, and ensuring teams can focus on what really matters—smooth, uninterrupted operations.

Why is MRO important in facility management?

The importance of MRO in facility management comes down to just one thing: reliability.

Every building, system, and piece of equipment has a specific purpose to fulfill.

Without the right maintenance, repairs, and operational supplies in place, even minor issues can snowball into costly problems.

- Better asset performance: Well-structured MRO ensures that assets perform at their best. Regular maintenance keeps equipment efficient, while timely repairs extend its life. This doesn’t just avoid breakdowns, but maximizes the return on investment for every asset under management.

- Less downtime, more continuity: Unplanned downtime is one of the biggest headaches in facility management. When a critical system goes offline, it disrupts everything around it. Strong MRO practices help prevent these interruptions by making sure the right spare parts, tools, and procedures are always ready when needed.

- Lower operational costs: Poorly managed MRO often manifests as waste—overstocked parts sitting idle, emergency repair bills, or overtime costs resulting from last-minute fixes. In contrast, a well-planned approach helps keep expenses predictable and under control.

- Support for sustainability goals: Today, facilities are under pressure to operate more sustainably.

Effective MRO supports this by keeping systems energy-efficient, reducing waste from poorly maintained assets, and ensuring compliance with safety and environmental standards.

So, MRO in facility maintenance is not just an operational detail; rather, it’s a strategic function.

Done well, it safeguards asset health, controls costs, and helps organizations run their facilities more sustainably and without disruptions.

Types of MRO supplies and categories

When people refer to MRO supplies, they’re talking about the wide range of items and materials necessary to keep facilities operating on a daily basis MRO supplies.

These can be grouped into three main categories, each serving a specific role in maintenance and facility operations.

- Maintenance supplies: These are the items used in routine upkeep and preventive care. Think of lubricants for machinery, cleaning chemicals for HVAC filters, or paints and coatings that protect surfaces. Having these supplies ready ensures assets stay in good working condition and last longer.

- Repair supplies: Even with the best maintenance practices, equipment eventually fails. This is where MRO products like spare parts, hand tools, or replacement components come into play. A facility team’s ability to respond quickly often depends on how well these supplies are stocked and managed.

- Operations supplies: These include the day-to-day essentials that support safe and efficient facility operations.

Some examples of this include personal protective equipment (PPE) such as gloves and helmets to cleaning materials, light bulbs, or even office consumables.

Example: A quick comparison of MRO categories

Every organization’s MRO list looks a little different, but the principle is the same: without the right MRO supply companies and sourcing strategies, facility teams risk delays, unplanned downtime, and unnecessary costs.

MRO process in organizations

The MRO process covers how an organization manages all the activities, supplies, and resources needed to keep its facilities and equipment operational. While the end goal is the same—reliable, efficient operations—the way companies approach MRO maintenance can vary widely.

- Manual processes: Many organizations still rely on spreadsheets, paper-based logs, or ad hoc ordering to track MRO activities. While this may work for small teams, it often leads to missing information, poor tracking of spare parts, and reactive rather than preventive maintenance.

- Digital processes: More advanced teams use software-driven MRO management systems to automate procurement, track inventory, and schedule maintenance tasks. Digital tools facilitate the standardization of processes, maintain real-time records, and ensure the availability of the right supplies when needed.

What are the common challenges in the MRO process?

Managing MRO effectively isn’t always straightforward; organizations often run into challenges that impact costs, efficiency, and reliability.

- Procurement delays – Sourcing critical spare parts often takes longer than expected, leading to downtime.

- Inventory issues – Overstocking ties up capital, while understocking creates operational risks.

- Supplier management – Without visibility into supplier performance and contracts, costs can rise, and lead times may increase.

- Fragmented data – Information scattered across departments makes it harder to plan ahead or analyze trends.

When MRO is handled reactively or without proper oversight, organizations face several risks:

> Unplanned downtime – critical equipment failures disrupt operations.

> Higher repair costs – emergency fixes are often more expensive than preventive measures.

> Safety concerns – missing supplies or delayed repairs can increase the chance of workplace incidents.

> Compliance issues – lack of documentation or missed maintenance schedules may lead to regulatory penalties.

> Shorter asset lifecycle – poor upkeep reduces equipment efficiency and longevity.

Best practices for optimizing MRO in facilities

Strong MRO practices don’t happen by chance; you need structure, the right tools, and consistent oversight.

Below are some proven MRO best practices that help facility teams reduce costs, enhance efficiency, and maintain smooth operations.

- Standardize suppliers and contracts: Working with a smaller pool of trusted suppliers helps reduce variability in quality, delivery times, and pricing. Standardized contracts also make it easier to control costs and negotiate better terms.

- Automate procurement and reordering: Manual ordering often leads to delays or stock imbalances. Automating these tasks ensures that critical MRO supplies are always available without overstocking, freeing up both time and working capital.

- Use data-driven forecasting: Analyzing past consumption and failure patterns allows facility managers to predict future needs more accurately. This helps avoid last-minute emergency purchases and keeps inventory levels balanced.

- Integrate with facility management software: When MRO maintenance is tracked in the same system as work orders, asset histories, and vendor data, it creates a single source of truth. This integration gives teams the visibility needed to make better decisions and reduce risks.

In short, to truly optimize MRO, facilities need a mix of process discipline and digital support. This combination makes operations more reliable and helps organizations stay ahead of unexpected disruptions.

Want full visibility into MRO inventory and supplier performance?

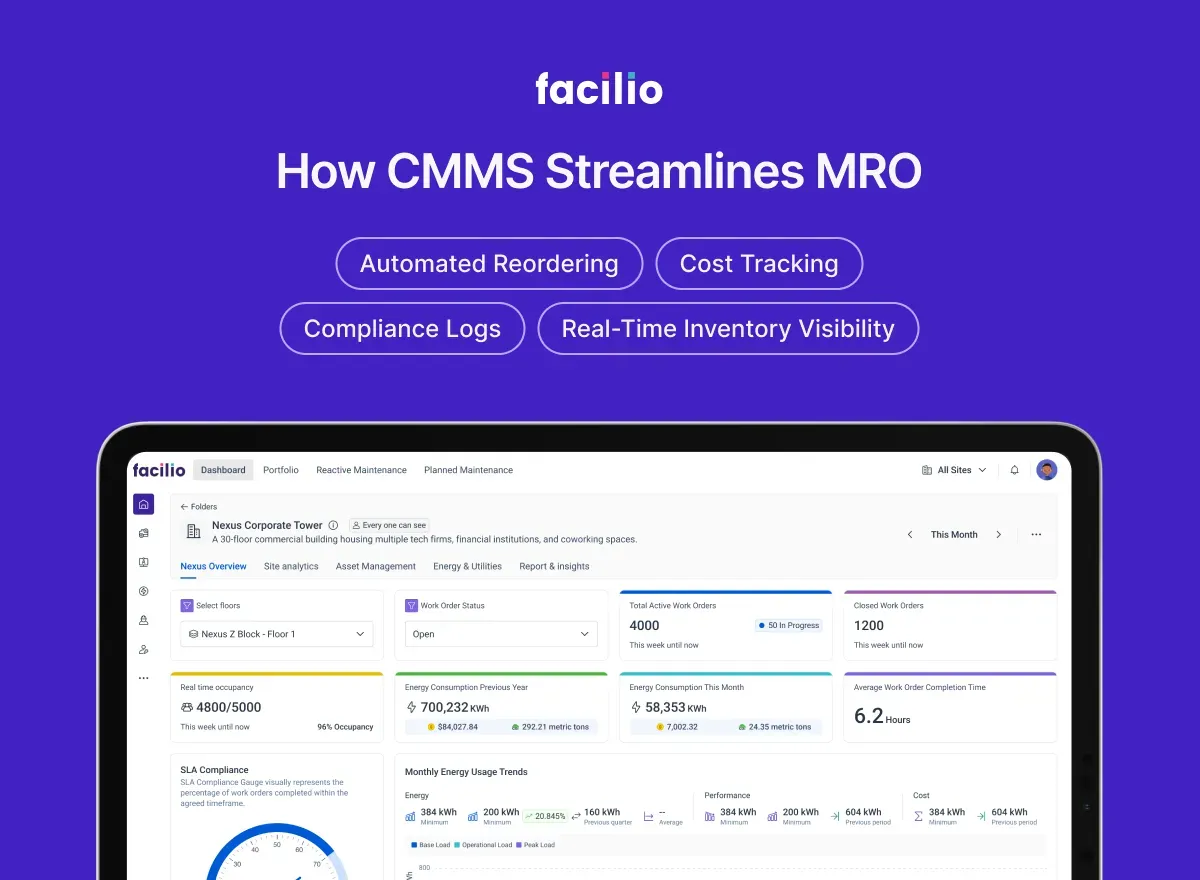

Try Facilio’s CMMS in action.How CMMS software streamlines MRO

Managing MRO through spreadsheets or manual logs can only go so far. As facilities become more complex, organizations require more effective ways to manage supplies, repairs, and maintenance tasks.

This is where MRO software like a modern CMMS makes the biggest impact.

A CMMS system centralizes all information related to MRO inventory management—from tracking spare parts to scheduling preventive maintenance.

So, instead of guessing when to reorder or scrambling to find a part, teams get real-time visibility into what’s in stock, what’s running low, and what’s already allocated to upcoming work orders.

Key benefits of using CMMS for MRO include:

- Automated reordering – set minimum stock levels and let the system generate purchase requests automatically.

- Cost tracking – monitor spend on spare parts, consumables, and repairs to spot cost-saving opportunities.

- Improved compliance – ensure maintenance and safety requirements are met with accurate logs and audit-ready records.

- Better planning – use data to forecast future MRO needs and avoid the waste of overstocking or the risks of shortages.

With Facilio’s Connected CMMS platform, these benefits go a step further.

Unlike standalone systems, Facilio links MRO data with real-time building operations and vendor management, creating a complete picture of facility health. This makes it easier for teams to cut downtime, reduce costs, and manage their facilities proactively rather than reactively.