Refrigerant Leak Detection: Methods of Detection and Regulatory Requirements

If a refrigerant leak went undetected, you would experience equipment breakdowns, energy losses, and possibly be charged up to $37,500 in daily fines for non-compliance with EPA (Environmental Protection Agency) refrigerant management and reporting .

The EPA 608 regulations require prompt repair of refrigerant leaks. Failure to do so attracts huge fines.

In this article, you’ll learn:

- The importance of refrigerant leak detection

- The tools and methods for detecting refrigerant leaks

- EPA refrigerant leakage and detection repair requirements

- How Facilio saves you hefty compliance fines

Let’s get started.

What is the importance of refrigerant leak detection?

The consequences of a refrigerant leak are disastrous. In addition to the leaking chemicals that can damage the Earth’s ozone layer, there are other burdens to consider.

Prevents additional costs

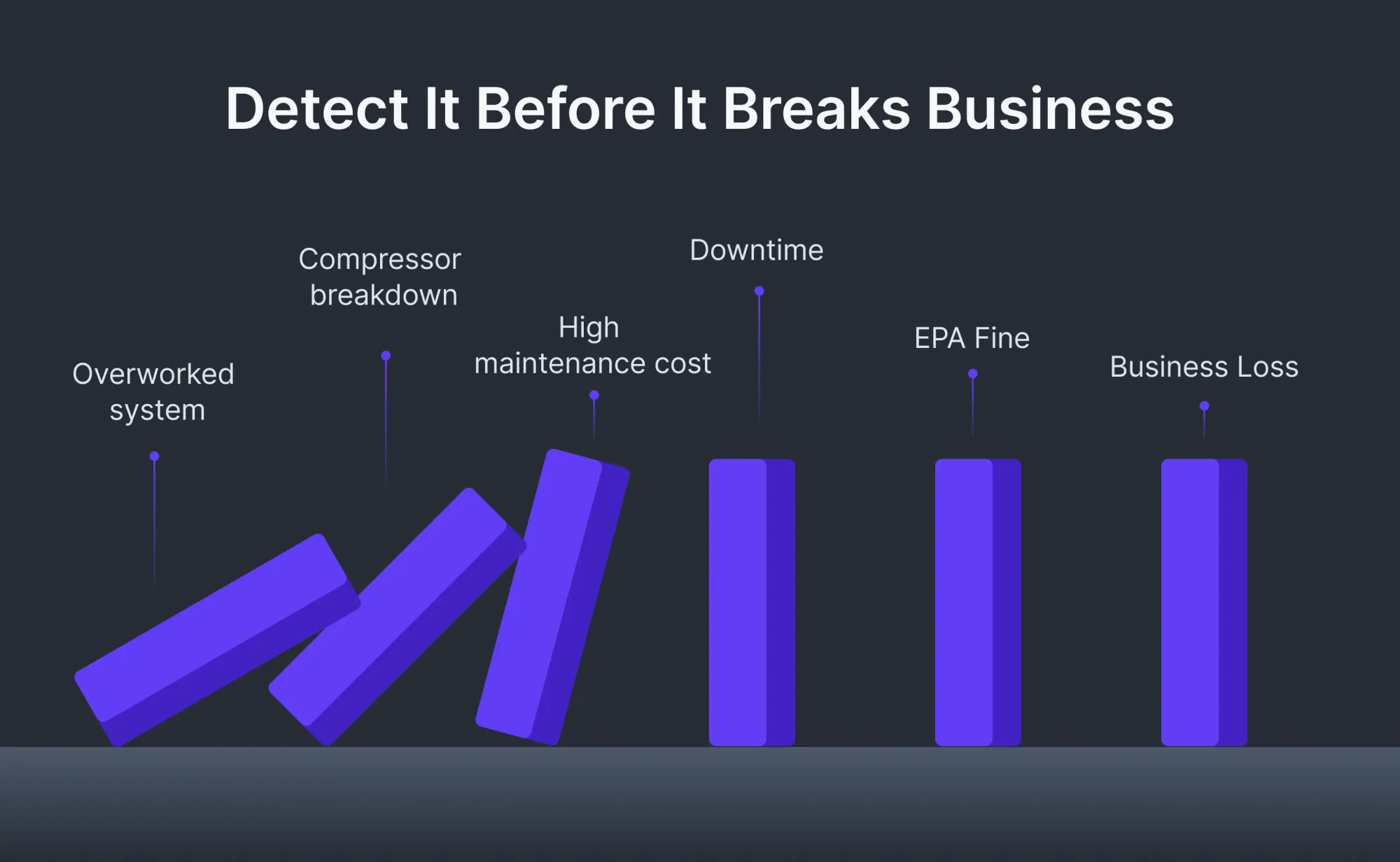

Picture this: your cooling system has a tiny, unnoticed leak. It might not seem like a big deal at first, but over time, that leak can grow, causing your system to work harder to maintain the same temperature. This translates to higher energy bills.

With a refrigerant leak detection system, you could prevent a tiny leak from growing, saving yourself extra costs.

Avoids frequent compressor breakdowns

A compressor is the heart of your cooling system. When there's a leak, your compressor must work overtime to keep your devices cool. This causes extra strain on the compressor, which can lead to more frequent breakdowns.

Prevents frequent unplanned downtime

You find yourself shelling out more and more money for repairs with a broken compressor and leaking refrigerant. This causes downtime for restaurants or retail facilities that rely heavily on refrigeration systems.

Food spoils, tempers flare, and sales take a nosedive.

Ensures adherence to regulatory requirements

Certain regulatory requirements are put in place to protect our environment and health, enforced by the EPA, the AIM Act (American Innovation and Manufacturing Act), and the Clean Air Act. These agencies cover various environmental issues, including air quality, emissions reduction, and hazardous waste management.

Read More:

- EPA Refrigerant Regulations: Elevate EPA 608 & Compliance Readiness

- Navigating Refrigerant Compliance Management: A Guide for Retail Managers

- Refrigerant Compliance Management Software in 2024

The EPA mandates that refrigeration facilities promptly repair leaks to minimize environmental impact. We’ll discuss other regulatory requirements in detail later in this article.

For now, let’s explore some methods for detecting refrigerant leaks.

Tools and Methods for Detecting Refrigerant Leaks

There are two major methods for detecting refrigerant leaks: the traditional and the electronic leak detection methods.

Traditional methods

- Soap bubble method: This is the cheapest method of detecting refrigerant leaks. It involves applying a soap solution to potential leak points and watching for bubbles. If there are any leaks, bubbles will appear.

- Ultraviolet method: This is otherwise known as the fluorescent dye method. A UV dye is introduced into the system and circulates within the refrigerant. If there is a leak, the dye escapes through the leak. When exposed to refrigerant, the dye becomes visible under UV light.

- Nitrogen detection method: This involves pressurizing the system with nitrogen. Firstly, the system is evacuated of refrigerant, ensuring no interference from the existing gas. Then, nitrogen is pumped into the system, pressurizing it. If there's a leak, a sound will be audible.

Electronic leak detection methods

- Heated diode: The heated diode detector sniffs out refrigerant leaks by heating the gas and sensing any changes in electrical resistance. It produces an alarm when a leak is detected, making it quick, efficient, and sensitive.

- Ultrasonic: It listens for the high-frequency sound emitted by leaking refrigerants, helping you track down elusive leaks—even in noisy environments.

- Infrared detector: The infrared detector uses infrared sensors to detect the presence of refrigerant gases. If there’s a leak, the refrigerant will absorb the infrared.

In retail, Automatic Leak Detection (ALD) systems help identify refrigerant leaks at the store level. However, traditional ALD systems rely on basic sensors and controllers that trigger alarms whenever set points are breached—without understanding the context. For instance, refrigeration systems naturally work harder during restocking or peak store hours.

However, ALD systems can’t differentiate between normal fluctuations and actual malfunctions, leading to frequent false alarms and unnecessary maintenance calls.

But, Facilio’s AI-powered Connected Refrigeration Software goes beyond standard ALD systems by intelligently interpreting sensor data in real-time.

Unlike conventional systems that simply raise alerts, Facilio’s platform analyzes the operational context, filters out false alarms, and automates corrective actions at the portfolio level.

Designed for multi-site retail operations, it provides continuous multi-site refrigeration monitoring systems, predictive insights, and automated compliance tracking, ensuring you stay ahead of EPA’s tightening regulations on leak management.

With Facilio, you don’t just detect refrigerant leaks—you prevent downtime, optimize performance, and ensure 100% regulatory compliance with a smarter, scalable, and ready-to-deploy solution.

EPA Refrigeration Leak Repair Requirements

As an operator or business owner, you’ve probably heard about the revised EPA regulations that start January 1, 2025.

The EPA’s Refrigeration Leak Repair Requirements aim to reduce the emissions of ozone-depleting substances (ODS) and greenhouse gases (GHGs) from refrigeration and air conditioning systems.

These EPA requirements aim to minimize the environmental impact of refrigerant leaks.

The regulations state that you must take corrective action when an appliance with a full charge of 50 or more pounds is discovered to be leaking ozone-depleting refrigerant at a rate that exceeds the applicable trigger rate.

The mandate of the revised EPA regulations further states that systems with over 50 pounds of refrigerant must repair leaks at a 20% annual leak rate.

Industrial Process Refrigeration (IPR): Systems require repairs at a 30% annual leak rate.

Comfort Cooling Systems (HVAC): Must address leaks at a 10% annual rate.

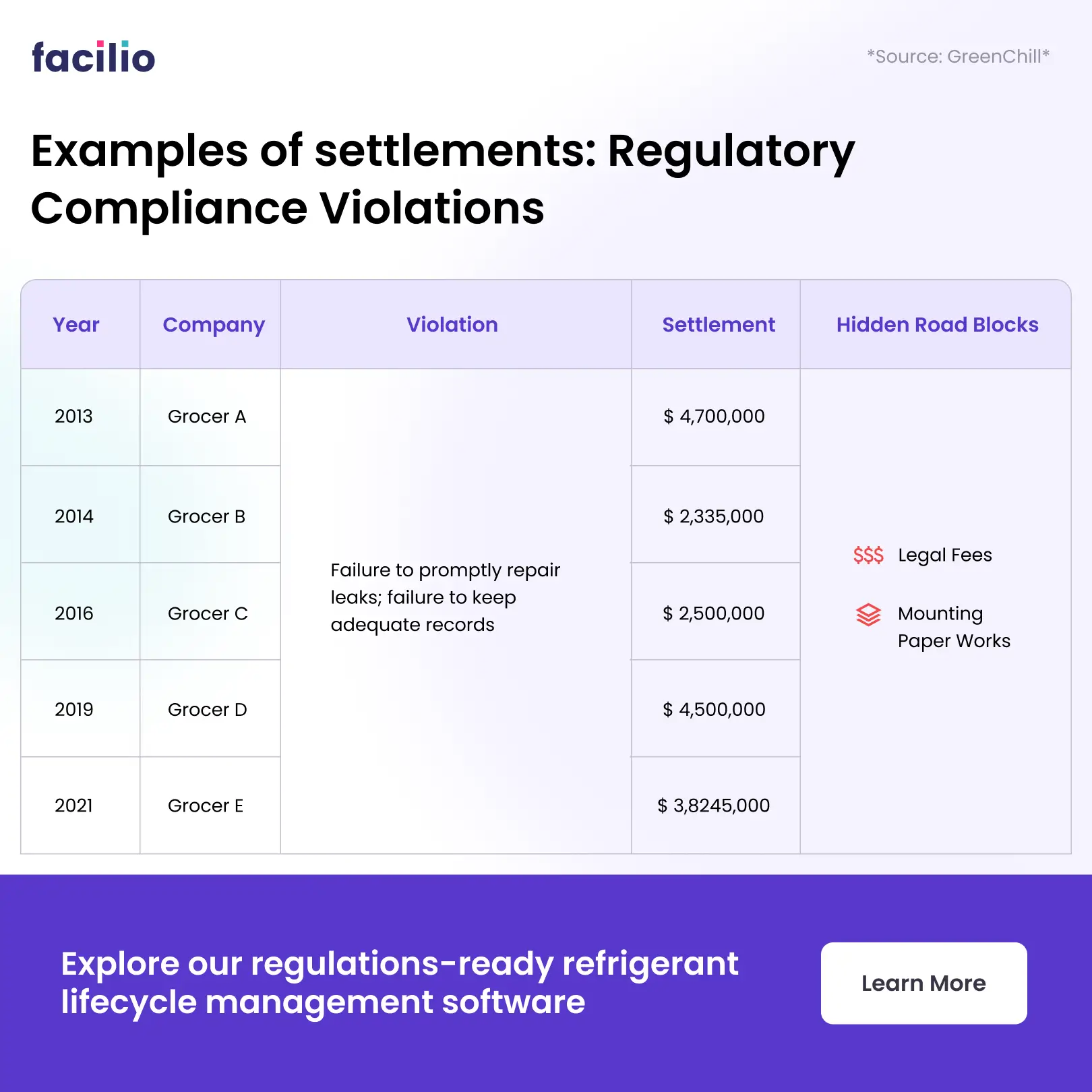

Failure to comply with these regulations can lead to hefty penalties, with fines reaching up to $69,733 per day. The latest revisions introduce stricter controls and lower leak thresholds, making compliance more challenging.

However, staying ahead of these regulations is possible with proactive prevention.

How Facilio saves you from costly compliance fines

Facilio’s AI-powered refrigerant compliance and leak detection software helps retail businesses stay compliant effortlessly.

The software lets you stay compliant without the headache—automated refrigerant checks, real-time leak alerts, and hassle-free reporting across all your sites.

The cost of refrigeration non-compliance in the USA

Failure to address refrigerant leaks can lead to staggering financial losses:

Ignoring leaks isn't just expensive—it’s unsustainable.

Facilio ensures compliance without the hassle of manual tracking and reactive fixes.

Why Facilio Outperforms Legacy Leak Detection Systems

Facilio is the One Unified Solution for Refrigeration Compliance and Efficiency

With Facilio, you can:

1. Detect refrigerant leaks early using context-aware, real-time monitoring

2. Automate inspections and manage refrigerant usage across multiple locations

3. Generate compliance reports effortlessly to meet EPA & EU regulations 4. Reduce operational costs by preventing unnecessary fines & legal expensesx

Don’t wait until a minor refrigerant leak snowballs into crippling fines and operational setbacks. Facilio’s AI-powered, compliance-ready solution not only detects leaks in real time but ensures airtight regulatory adherence without the hassle.

Supermarket chains like King Kullen have already reduced refrigerant leak rates by 40%, automating inspections and reporting to stay compliant.

Say goodbye to reactive fixes and hello to proactive refrigerant management that saves you time, money, and compliance headaches.

Less risk, no fines, and smooth operations.

Frequently Asked Questions

1. What is the best refrigerant leak detection method for multi-site retail operations?

The best method depends on factors like accuracy, scalability, and compliance requirements. While electronic leak detection methods offer high sensitivity, they alone aren’t enough for large-scale operations. Facilio’s AI-powered refrigerant compliance software combines real-time leak detection with automated reporting, ensuring compliance across multiple locations while minimizing false alarms.

2. What is the most reliable leak detection method, and why?

Electronic refrigerant leak detection methods are generally considered the most reliable due to their sensitivity and accuracy. However, without an intelligent monitoring system, even the best sensors can trigger false alarms or miss critical leaks. Facilio’s connected refrigeration software adds context to sensor data, reducing false alerts and enabling proactive maintenance to prevent costly refrigerant losses.

3. How can I ensure refrigerant compliance across multiple retail locations?

Managing compliance at scale requires centralized monitoring, automated record-keeping, and proactive leak detection. Facilio’s software provides real-time insights, automated compliance reporting, and AI-driven alerts to help retail businesses stay ahead of EPA, AIM, and Clean Air Act regulations effortlessly—reducing the risk of penalties and operational disruptions.

4. What are the key compliance requirements for refrigerant leak detection?

Regulatory standards, including the EPA, AIM Act, and Clean Air Act, mandate timely leak detection, repair, and record-keeping. Large facilities must ensure leaks don’t exceed permitted thresholds and maintain detailed documentation of inspections and repairs.

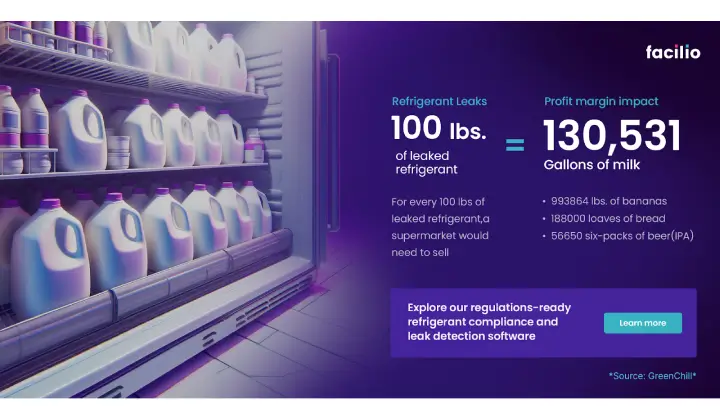

5. What is the financial impact of refrigerant leaks on my retail business?

Refrigerant leaks don’t just lead to regulatory fines (up to $69,733 per day); they also increase energy consumption and impact cooling efficiency. To put this into perspective, replacing 100 tons of leaked refrigerant would require selling over 130,000 gallons of milk. Facilio helps retail chains mitigate these costs with AI-powered leak prevention and automated compliance, ensuring maximum savings and operational efficiency.

More from Facilio