Failure Mode and Effects Analysis (FMEA): A Step-by-Step Guide for Modern Maintenance

Unplanned downtime costs Fortune 500 manufacturers $1.5 trillion each year—proof that waiting for failure simply isn't an option. That’s why leading facility and asset managers use FMEA (Failure Mode & Effects Analysis) as their frontline risk tool. FMEA finds hidden weaknesses before they cost you time, safety, or compliance.

This guide breaks down the FMEA process, explains its real-world maintenance and facility impact, shows how it fits alongside tools like CMMS, and delivers best practices, use cases, and must-see benchmarks.

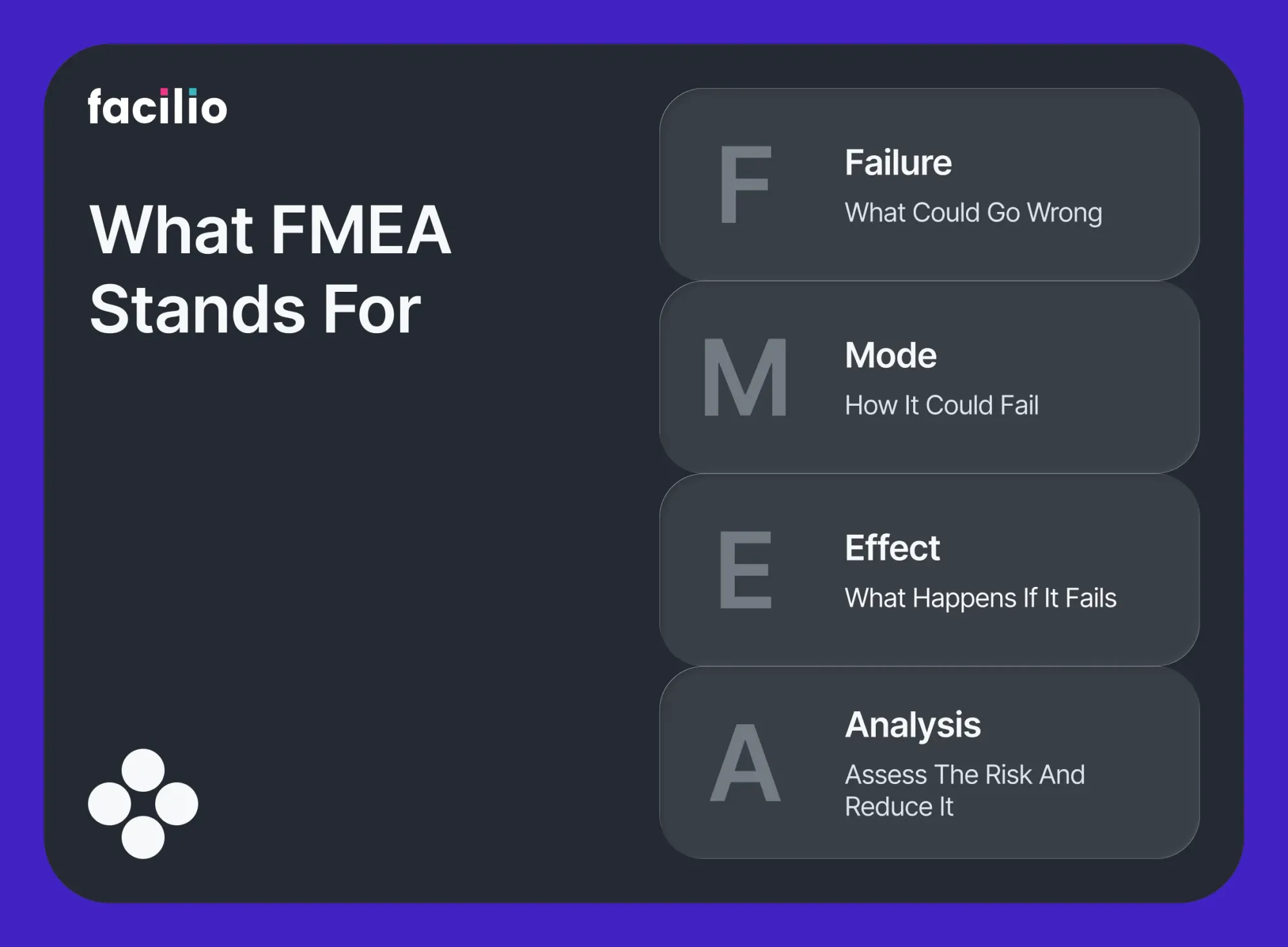

What is FMEA? A Smart Approach to Preventing Failures

Failure Mode and Effects Analysis (FMEA) is a structured, step-by-step methodology for finding, ranking, and eliminating failure risks in assets, processes, or systems before they cause disruption. Born in the 1950s for aerospace reliability, FMEA is now a staple in every top-tier maintenance and facility management program.

- Failure Modes: Specific ways a function or component can go wrong (e.g., bearing seizes, voltage spike, improper assembly)

- Effects: The consequences of that failure, from minor defects to major safety incidents

FMEA goes beyond gut feel. It uses scoring (Severity, Occurrence, Detection) to assign a Risk Priority Number (RPN) so teams can act where it matters most.

"FMEA is not a replacement for engineering know-how; it elevates it. By assembling a cross-functional team—maintenance, engineering, quality, and operations—organizations blend technical acumen with frontline experience."

Types of FMEA: Design vs Process

FMEA can be of two types: design FMEA & process FMEA. The key differences between these two are:

To dive deeper into process-specific risk ranking, explore the detailed guide to process failure mode effects analysis for step-by-step examples and control plan templates.

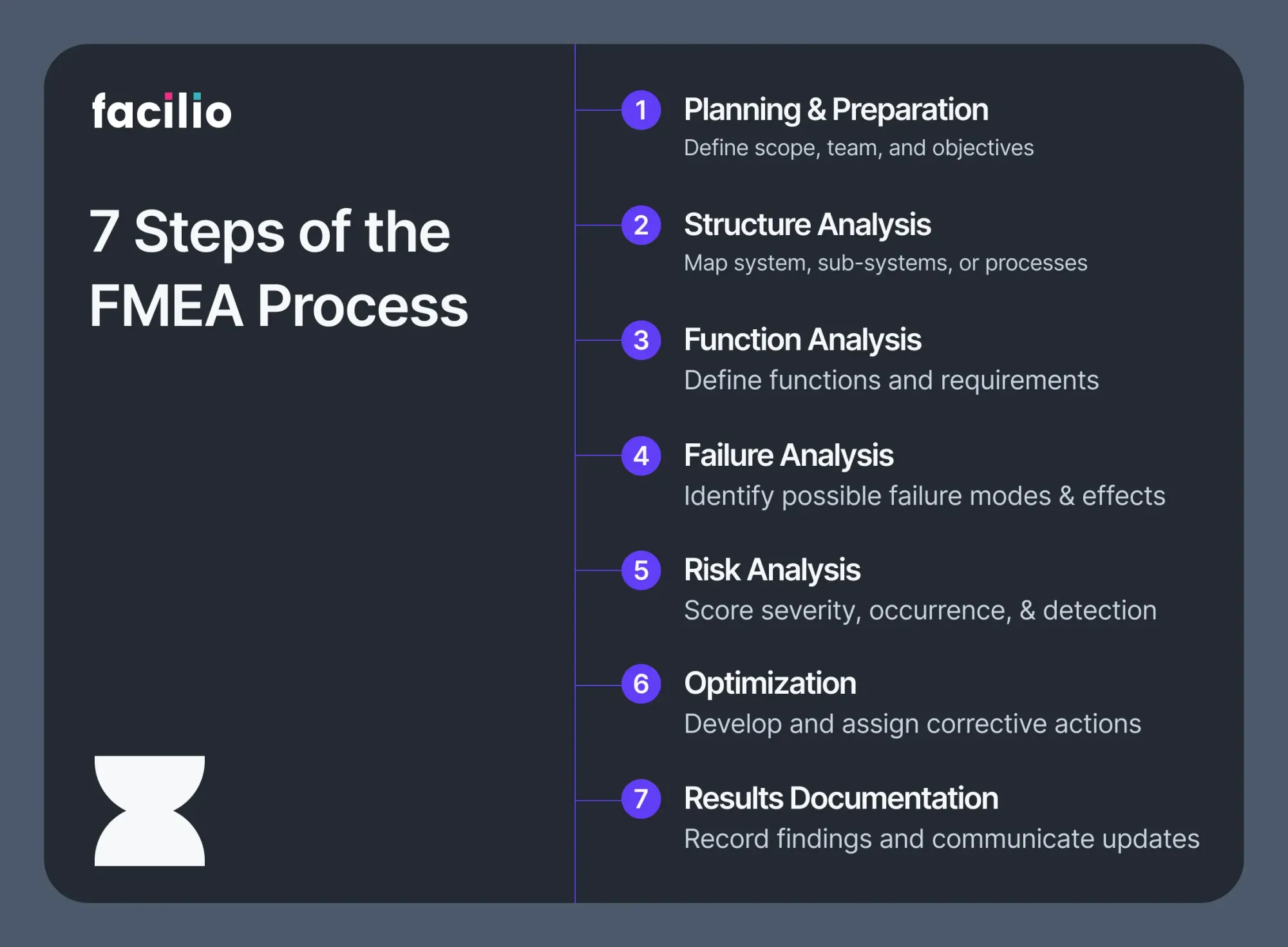

The 7 Steps of FMEA

FMEA can look complex, but it’s built on 5 clear phases, each with rigorous sub-tasks to ensure nothing slips through the cracks.

1. Define Scope and Prepare Foundation

- Set system/process boundaries: Specify exactly what’s to be analyzed (asset, process, or product line).

- Form a cross-functional team: Bring maintenance, design, quality, ops, and relevant stakeholders to the table.

- Compile supporting docs: Pull historical failure (8D), FMA reports, BOMs, interface diagrams, and past control plans for context.

- Map the system: Use block diagrams (DFMEA) or process flows (PFMEA) to visualize every interface and step.

💡 Well-prepared FMEA teams uncover 2x more failure modes than those who “just start with a worksheet.”

2. Break Down Functions, Failure Modes, and Effects

- Decompose system/process: Break down into sub-systems, assemblies, process steps, or components.

- Define specific functions: Each in verb-noun and measurable outcome form (“contain pressure,” “seal fluid pipeline”).

- Identify failure modes: How could this function go wrong? List all—total, partial, intermittent, over, or unintended function.

- Map effects: For each failure mode, describe the downstream impact on system, customer, regulation, or connected process.Example: HVAC coil - Failure Mode: “Internal corrosion.” Effect: “Reduced airflow, leads to asset shutdown and possible compliance breach.”

- Assign Severity rating (1–10): Score each effect. 1 is negligible, 10 is catastrophic/safety threat.

- If Severity ≥9, trigger immediate review, regardless of other scores.

3. Identify Root Causes, Controls, and Score Occurrence

- Pinpoint potential causes: Use historical failure, field experience, and design/process knowledge to map why these failures might happen.

- Go beyond “operator error”—dig to the underlying cause (lack of training? poor interface?)

- Document prevention controls: What’s in place now to prevent each cause? (E.g., SOP, poka-yoke, supplier checks, design alarms)

- Assess Occurrence rating (1–10): How likely is this failure/cause, in current reality?

- 1 = “Basically never seen”

- 10 = “Common/frequent in this or similar processes”

- Tag special characteristics: Some failures are critical for safety or compliance—note as such for audit/traceability.

"Equipment failures account for 42% of unplanned downtime and $50 billion in annual losses in US manufacturing. (source: iiot-world.com)"

4. Evaluate Detection Controls and Calculate RPN

- Map detection controls: Document how (or if) current inspection, testing, or monitoring will catch failure before it becomes critical. (Design FMEAs = does the design get tested? PFMEA = does QC identify the defect before shipment/use?)

- Assign Detection rating (1–10): 1 = "Virtually always caught," 10 = "Almost never detected in time."

- Calculate Risk Priority Number (RPN): For each failure mode/cause:

- RPN = Severity × Occurrence × Detection (Range: 1 to 1,000+)

- Action thresholds: Most teams flag items with RPN > 120 or any Severity/Occurrence > 8 for immediate action.

With industrial downtime costing $1.5T globally (Deloitte), focusing on high-RPN items drives the biggest return.

5. Prioritize, Act, and Continuously Re-evaluate

- Develop corrective actions: For high-scoring failure modes, create targeted actions (redesign, add process control, improve detection, training).

- Assign responsibility and timelines: Who owns each action? What’s the deadline? When will impact be reviewed?

- Re-score after mitigation: Once actions are implemented, reassign Severity, Occurrence, and Detection, then recalculate RPN.

- Document everything: Effective FMEA is always well-documented. Updates are kept in a living file—never a “one-and-done” event.

💡 FMEA is not static. It’s updated after major design/process changes, recurring incidents, or periodically for continuous improvement.

Key Aspects That Make FMEA Effective

- Proactive: Catches risks before failures, unlike reactive “fix it when it breaks” processes. 80% of failures are preventable with techniques like FMEA (US Dept of Energy).

- Systematic: Every step is methodical and auditable.

- Quantitative: Assigns objective scores for risk-based decisions.

- Collaborative: Leverages the combined knowledge of design, maintenance, quality, and end users.

- Continuous: A living document—updated with every process or product evolution.

When to Use FMEA

- Initial design: Stop flaws before products/processes go live.

- Redesign or process change: Validate that updates don’t introduce new risks.

- Pre-control plan: Identify where to focus inspections and controls.

- After incidents: Use FMEA as a foundation for root-cause analysis and corrective action.

- Regular risk reviews: Stay compliant and reliable as assets (and codes) evolve.

Yet, 44% of facilities still rely on run-to-failure maintenance—highlighting why structured tools like FMEA are no longer optional.

Learn more about maintenance program evolution ➔

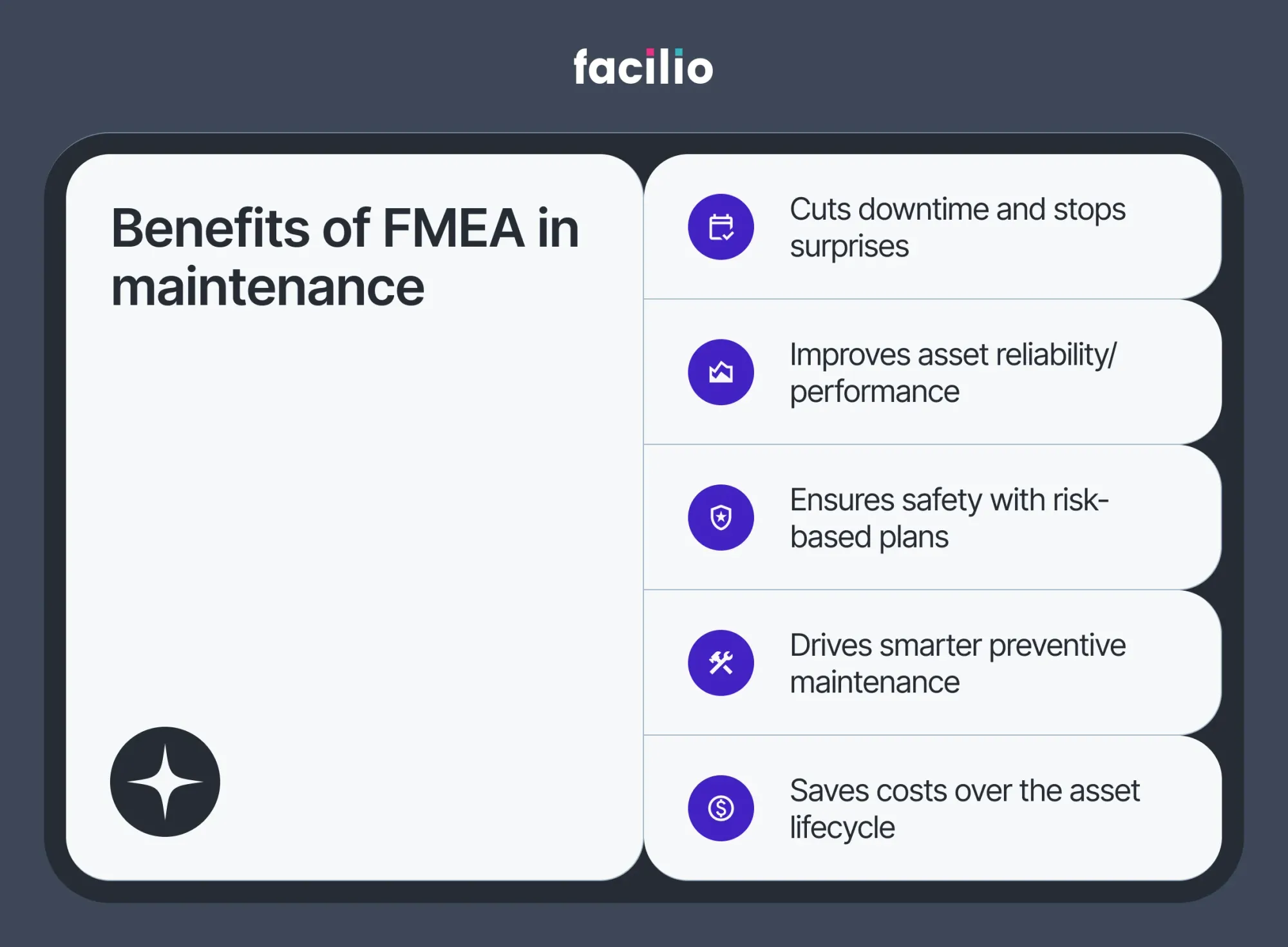

What Are the Real-World Benefits of FMEA?

- Reduces downtime: Enables smarter preventive maintenance, avoiding unplanned outages.

- Improves reliability: Strengthens design/process so assets work as intended, longer.

- Enhances safety & compliance: Flags failures before they reach users or violate code.

- Saves money: Proactive action can save 12–18% in annual maintenance costs vs. run-to-failure.

- Boosts efficiency: Focuses resources on the issues with real impact.

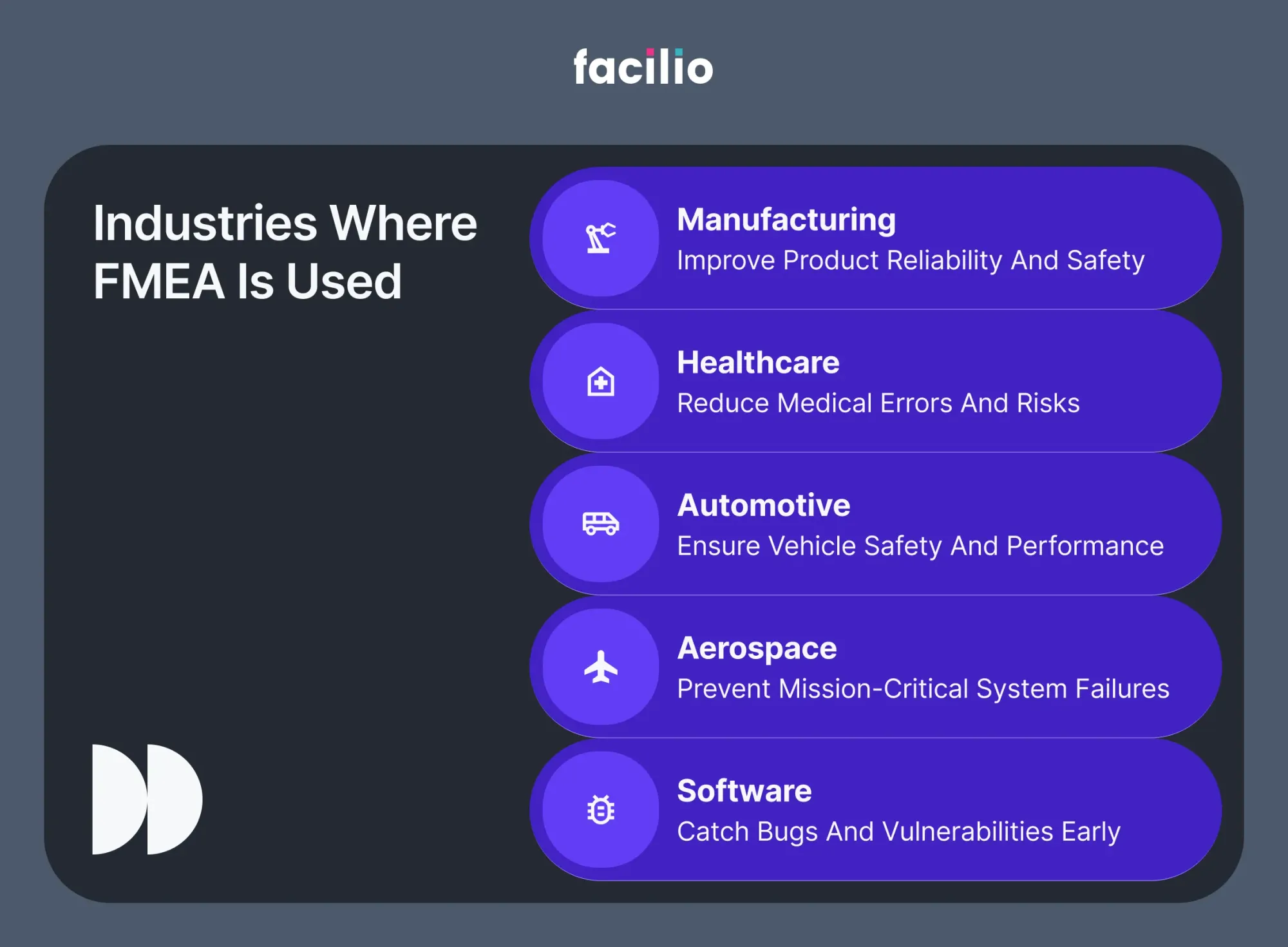

How FMEA Transforms Maintenance in Key Industries

Manufacturing

Process FMEA targets production bottlenecks and chronic asset failures. Maintenance teams use the findings to build PM schedules, optimize spares, and develop rapid-response plans.

→ Result: Lower scrap and rework, increased throughput, fewer shutdowns.

Healthcare

Integrated with the CMMS for healthcare, FMEA identifies hospital system vulnerabilities (HVAC, back-up power, sterilization) before patient safety is at risk.

→ Result: Higher uptime, less risk to patients, audit-ready compliance.

Pharmaceuticals

Facility engineers use FMEA to prioritize maintenance of cleanroom HVAC, water loops, and critical utilities—aligning with GMP/validation.

→ Result: Minimizes contamination, maintains readiness for regulatory audit.

Commercial Facilities

FMEA helps office, retail, and edtech facility managers pro-actively plan asset onboarding and long-term capital repairs, focusing on systems most likely to impact occupants.

→ Result: Smoother transitions and less OPEX spent on emergency repairs.

Utilities & Energy

Applied to substations, backup power, critical grid equipment; FMEA outputs inform inspection intervals and replacement strategies.

→ Result: Greater system uptime, compliance with NERC/FERC and other regulators.

Automotive

FMEA is used for optimizing design at the engineering phase and for maintenance routines in high-throughput plants.

→ Result: Up to 40% drop in warranty claims and drastically fewer field recalls (source: AIAG).

Education & Campus OperationsFacility management teams use FMEA for building infrastructure (fire alarms, elevators, HVAC) to ensure safe, disruption-free learning.→ Result: Reduced class downtime, increased campus safety, simplified compliance.

In fact, nearly 60% of maintenance leaders using CMMS tools say FMEA is critical for driving a robust preventive maintenance program.

Conclusion: Make Proactive Risk Management Routine—Not a Fire Drill

FMEA moves maintenance from “run-to-failure” firefighting to evidence-based, risk-driven prevention. Whether you operate a factory, campus, or global asset portfolio, using FMEA helps eliminate hidden vulnerabilities, improve safety, and build a facility operation that never sleeps.

Ready to turn risk into ROI? Talk to Facilio about embedding FMEA logic inside your maintenance and reliability management—and future-proof your operations, end to end.

Get started now.

Learn how you can seamlessly perform routine maintenance activities.

Frequently Asked Questions (FAQs)

What are the 5 steps of the FMEA process?

The fundamental five steps of FMEA are:

- Recognizing possible failure modes and their consequences

- Evaluating the severity level of each failure

- Assessing the probability of occurrence for each failure

- Determining detection capabilities

- Calculating a risk priority number

What is a FMEA process?

FMEA (Failure Modes and Effects Analysis) is a methodical, forward-looking analytical tool used to examine processes where potential harm could arise.

During FMEA implementation, a cross-functional team collaborates to anticipate and document potential system failures, including their location, nature, and magnitude.

Is FMEA a Six Sigma?

FMEA represents an essential component within Six Sigma methodology, particularly integrated into the DMAIC (Define, Measure, Analyze, Improve, Control) structure. It provides a methodical way to recognize and evaluate potential failure modes across different industrial processes.

What are the 7 steps of FMEA?

The seven-step FMEA methodology includes:

- Initial planning and preparation

- Structural analysis

- Functional analysis

- Failure analysis

- Risk evaluation

- Optimization processes

- Documentation of results

What is a good example of FMEA?

A practical FMEA example can be analyzing a seat belt installation procedure at an automotive manufacturing facility.

In this example, multiple potential failure scenarios are identified, with each assigned risk priority numbers to determine which issues require immediate attention for process enhancement.

What are the 5 T's in FMEA?

The 5T framework in FMEA includes five key elements:

- Intent

- Timing

- Team

- Tasks

- Tools

These components must be clearly established before beginning the analysis to optimize resource allocation and minimize errors that could require later corrections.

Which tool is used in FMEA?

Key FMEA tools include:

- FMEA worksheets and software - Structured templates and specialized programs like Minitab or ReliaSoft

- Cross-functional team meetings - Collaborative sessions with engineering, quality, and operations experts

- Risk Priority Number (RPN) calculators - Tools that multiply Severity × Occurrence × Detection ratings

- Historical data - Past failure records and maintenance logs for informed analysis

When should FMEA be applied?

FMEA should be used for:

- Product/process development - Before design finalization to prevent failures

- System modifications - When making changes to existing processes

- High-risk operations - Where failures cause safety hazards or significant costs

- Regulatory compliance - When required by industry standards

- Continuous improvement - As part of Six Sigma or quality enhancement projects