EPA 608 Compliance: The Retailer’s Guide to Avoiding Fines and Managing Refrigerant Risk

Why retailers can’t ignore EPA 608 anymore

In early 2024, Gristedes, a popular supermarket chain in New York, was fined over $400,000 by the U.S. Environmental Protection Agency (EPA) for violating Section 608 of the Clean Air Act.

Their offense?

Failure to repair refrigeration leaks, inadequate documentation, and failure to follow required leak monitoring protocols. Gristedes isn’t alone. Retailers with refrigerant-heavy operations are squarely in the EPA’s crosshairs.

EPA Section 608 isn’t just a box to check. It’s a detailed set of rules that govern how refrigerants—especially ozone-depleting substances and hydrofluorocarbons (HFCs)—are handled, tracked, and reported.

For grocery chains, convenience stores, and other retailers with commercial refrigeration systems, this regulation is a legal and operational imperative.

This guide will walk you through everything you need to know about EPA 608 as a retailer—from technician certifications and leak thresholds to compliance checklists and how technology can take the burden off your teams.

What is EPA Section 608, and why retailers should care

EPA Section 608 is part of the Clean Air Act and regulates how refrigerants are managed throughout their lifecycle—from installation and service to recovery and disposal. Its primary purpose is to prevent emissions of ozone-depleting substances (like CFCs and HCFCs) and high-global warming potential refrigerants (like HFCs).

Who it applies to: Any facility operating equipment that uses regulated refrigerants, including:

- Supermarket refrigeration systems

- Walk-in and reach-in freezers

- Rooftop HVAC units

- Cold storage and distribution systems

Retailers often fall short not because they ignore the law, but because they underestimate its complexity. What seems like a minor leak or delay in repairs can snowball into a regulatory breach, especially if documentation isn’t airtight.

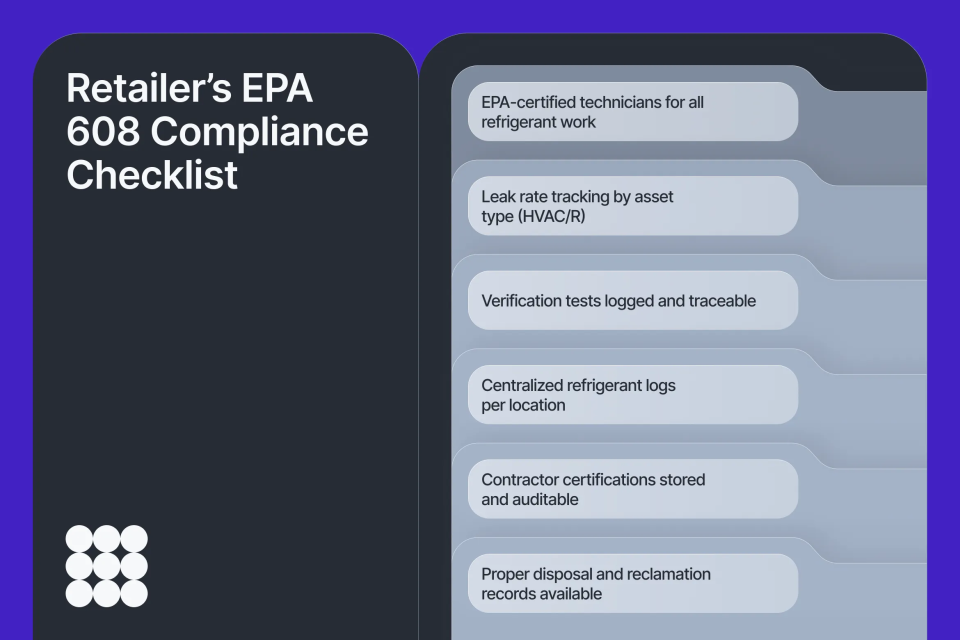

2. Key EPA 608 compliance requirements (retail edition)

Retailers must comply with a combination of technician, equipment, and process-level requirements.

Here are the critical ones:

a. Technician Certification: Only EPA-certified technicians may service appliances containing regulated refrigerants. Certification types include:

- Type I: Small appliances (e.g., stand-alone coolers)

- Type II: High-pressure appliances (e.g., HVAC systems)

- Type III: Low-pressure appliances

- Universal: Covers all appliance types

b. Leak Rate Thresholds (Annual):

- Commercial refrigeration: 20%

- Comfort cooling (HVAC): 10%

- Industrial process refrigeration: 30%

If leak rates exceed these thresholds, you must repair them within 30 days (or 120 days with approved retrofit/retirement plans).

c. Leak Inspections:

- Appliances with >50 lbs. of refrigerant must undergo regular leak inspections.

- Quarterly or annual, based on leak history and system type.

d. Recordkeeping:

- Amount of refrigerant added/removed

- Leak inspection reports

- Repair dates and verification tests

- Contractor EPA certifications

e. Disposal Requirements: Appliances must be evacuated before disposal. Vendors must provide certificates of proper refrigerant reclamation.

Need help staying on top of refrigerant logs and leak thresholds?

Facilio lets you track every charge, repair, and follow-up—down to the asset level—with built-in EPA 608 logic.

See how Facilio handles refrigerant tracking →3. Real penalties for getting it wrong: Retailer examples + costs

The EPA has stepped up enforcement, and retailers are increasingly on the hook. Let’s look at real cases:

Gristedes (2024):

- Fine: $400,000+

- Violations: Leaks above allowable thresholds, failure to repair, inadequate recordkeeping

Trader Joe’s (2016):

- Fine: $500,000 civil penalty + $2 million mitigation

- Cause: Failure to identify and repair leaks; over 25% annual leak rate

Costco (2014):

- Fine: $335,000 + $2 million equipment upgrade requirement

Beyond monetary fines, the reputational damage is harder to quantify.

Public announcements, investor scrutiny, and customer trust can all take a hit. For multi-site retailers, one compliance failure can cascade across locations.

4. What compliance looks like in practice: Systems, processes, and operational clarity

EPA 608 compliance isn’t just about having certified technicians; rather, it's about building a coordinated, repeatable system across your entire retail footprint. Compliance becomes operationally sustainable when every stage of refrigerant handling is standardized, traceable, and audit-ready.

Here’s what that looks like in practice:

1. Vendor accountability and technician validation

Many violations begin with third-party work that slips through the cracks. To stay compliant, retailers must ensure:

- All contractors working on HVAC/R systems are EPA-certified, with Type II or Universal certification depending on appliance type.

- Certifications are verified before dispatch and logged in a centralized system—not buried in local files.

- Post-repair documentation (including leak location, amount of refrigerant added, and date of service) is submitted within 24–48 hours and stored centrally.

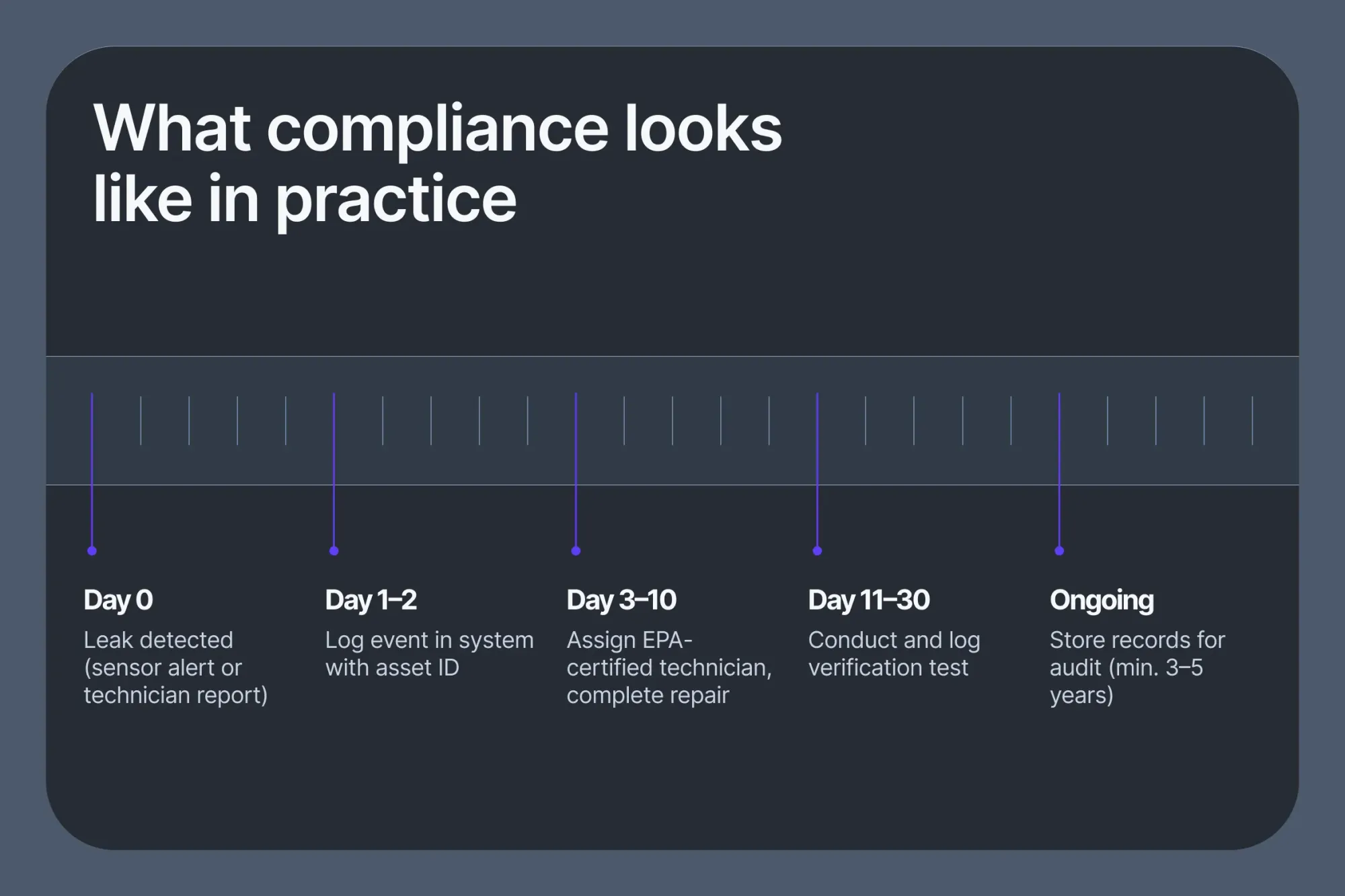

2. Leak event lifecycle: Detect → Log → Repair → Verify

EPA 608 sets strict timelines for repairing leaks once discovered, depending on appliance type and leak rate. Retailers must operationalize this by:

- Using smart sensors or technician reports to detect suspected leaks

- Logging the leak event in a system that timestamps discovery

- Initiating repairs within the 30-day window (or 120 days if granted extensions for large systems or parts delays)

- Conducting verification tests post-repair, such as electronic leak checks or pressure decay tests

- Maintaining a full digital trail for each event—who reported, what was done, and when verification occurred

Any missed step or undocumented verification exposes your organization to EPA scrutiny.

3. Refrigerant tracking: Asset-level granularity

Retailers must track every ounce of refrigerant added or recovered. In practice, this means:

- Every HVAC/R asset has a unique identifier and corresponding refrigerant profile

- Service logs track refrigerant charges, top-ups, and removals per visit

- Refrigerant usage thresholds are monitored by asset type (comfort cooling vs. commercial refrigeration)

- Patterns in leak frequency or excessive top-ups are flagged to identify chronic issues before they escalate

Spreadsheets and paper logs can’t support this at scale. You need a system that correlates refrigerant activity to specific assets in real time.

4. Centralized documentation and accessibility

EPA audits don’t just review your current practices—they examine historical records over 3–5 years.

Being compliant means being ready with:

- Digitized service records, including leak repair logs, verification test results, and refrigerant usage

- Technician certifications and proof of EPA credentialing

- Disposal records for recovered refrigerant and proper reclamation documentation

- A single source of truth—accessible across teams, not spread across individual sites or inboxes

This centralized recordkeeping is critical, especially for multi-site retailers managing dozens or hundreds of locations.

5. Internal audits and cross-site visibility

EPA enforcement is growing more proactive. Waiting for an audit—or worse, a violation letter—is no longer viable. Leading retailers are implementing:

- Quarterly compliance audits, spot-checking leak events, exceeding and documentation across locations

- Dashboards that surface refrigerant trends, missing certifications, or overdue follow-ups

- Exception reporting to catch sites falling out of compliance or consistently exceeding leak rate thresholds

- Portfolio-wide benchmarking, so teams can compare refrigerant usage and leak response timelines by store, region, or vendor

This transforms refrigerant compliance from a reactive function to a proactive risk mitigation program.

One fine can expose gaps across your entire portfolio.

Facilio helps you unify leak management, vendor proof, and repair workflows—so no site slips through the cracks.

Talk to us about multi-site refrigerant control →5. How technology helps simplify EPA 608 compliance

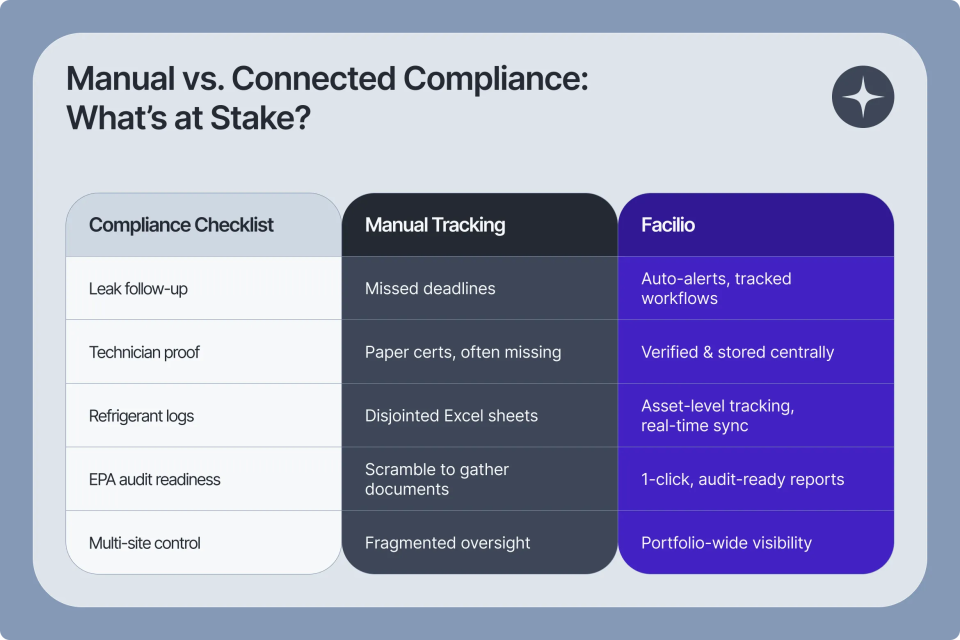

Retailers managing refrigerants across multiple sites often rely on paper logs, Excel files, or disjointed contractor reports—a recipe for missed deadlines and audit risk. Connected refrigerant compliance tools change that.

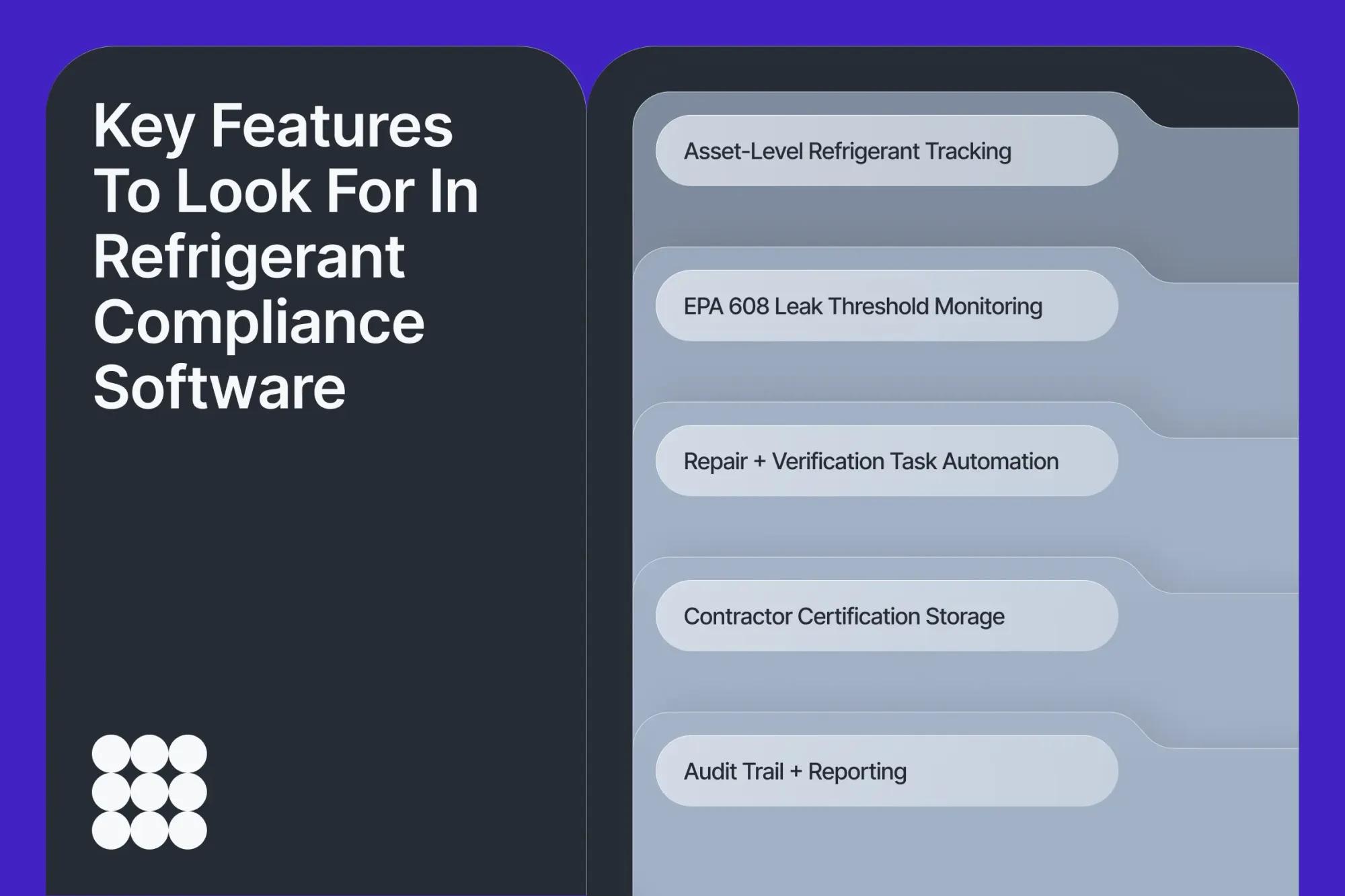

Here’s what modern software can automate:

- Live leak tracking: Get alerts when refrigerant thresholds are breached

- Technician verification: Ensure only certified techs are assigned

- Repair workflow automation: Auto-reminders for 30-day repair deadlines and 10-day verifications

- Centralized dashboards: View refrigerant use and leak rates portfolio-wide

- Audit-ready reports: Export all EPA-mandated data in one click

6. Facilio spotlight: One platform for leak compliance, vendor control, and audits

Facilio’s Connected Refrigeration platform is designed for exactly this: simplifying refrigerant compliance across large, complex retail portfolios.

Here’s how leading retailers use it:

- Live tracking: Auto-detect leak events and trigger next steps

- Vendor coordination: Assign certified contractors, log all actions

- Central data hub: Access asset history, leak trends, PRs, and verification tests from one place

- Audit defense: Pull EPA-compliant reports with timestamps, tech signatures, and asset logs.

Turn refrigerant risk into operational advantage with Facilio’s Connected Refrigeration Software

EPA 608 compliance isn’t just a regulatory checkbox—it’s a litmus test for how prepared your operations really are. Inconsistent leak handling, technician gaps, and scattered records don’t just invite EPA scrutiny—they signal deeper inefficiencies across your FM workflow.

Retailers that shift from reactive compliance to proactive refrigerant management are seeing the benefits compound:

- Fewer unplanned outages and emergency repairs

- Centralized, auditable records across all locations

- Streamlined contractor oversight and cost control

- Tangible progress toward sustainability and ESG goals

It’s a transformation already underway.

TutenLabs, a leading O&M provider in Latin America, partnered with Facilio to centralize HVAC/R oversight across 900+ assets—automating leak tracking, technician coordination, and compliance reporting at scale.

Read how they scaled refrigerant control across portfolios →

Whether you operate 20 stores or 2,000, Facilio’s Connected Refrigeration solution gives your teams the visibility and control to make compliance routine—not a fire drill.

Let’s talk about how Facilio can help you stay compliant, portfolio-wide.

Stay ahead of the industry and ever-evolving EPA regulations with Facilio

Schedule My DemoMore from Facilio