Autonomous Maintenance (AM): Meaning, Benefits, 7 Steps to Implement

Autonomous maintenance (AM) is a maintenance methodology that enables operators to take charge of their equipment's basic upkeep, such as cleaning, inspection, and lubrication.

AM is intended to reduce the dependency on maintenance technicians for routine tasks, enabling them to focus on more complex issues.

Rooted in the 1970s Total Productive Maintenance framework developed by Seiichi Nakajima, AM is built on two core principles: use equipment properly, and keep it running smoothly with regular care. It’s simple but powerful.

What used to take months of training and heavy resources is now easier than ever to roll out, thanks to CMMS platforms that guide, track, and optimize every AM task.

In this blog, we’ll walk through how autonomous maintenance works, why it pays off, and how a CMMS platform makes it practical for any forward-thinking operation.

What is Autonomous Maintenance?

Autonomous maintenance refers to a proven methodology where front-line operators are entrusted with, and trained for, routine tasks involved in basic equipment care.

At its very core, the autonomous maintenance meaning centers on transferring daily upkeep duties, such as cleaning, inspection, and simple corrective measures, from specialized technicians to the equipment users themselves.

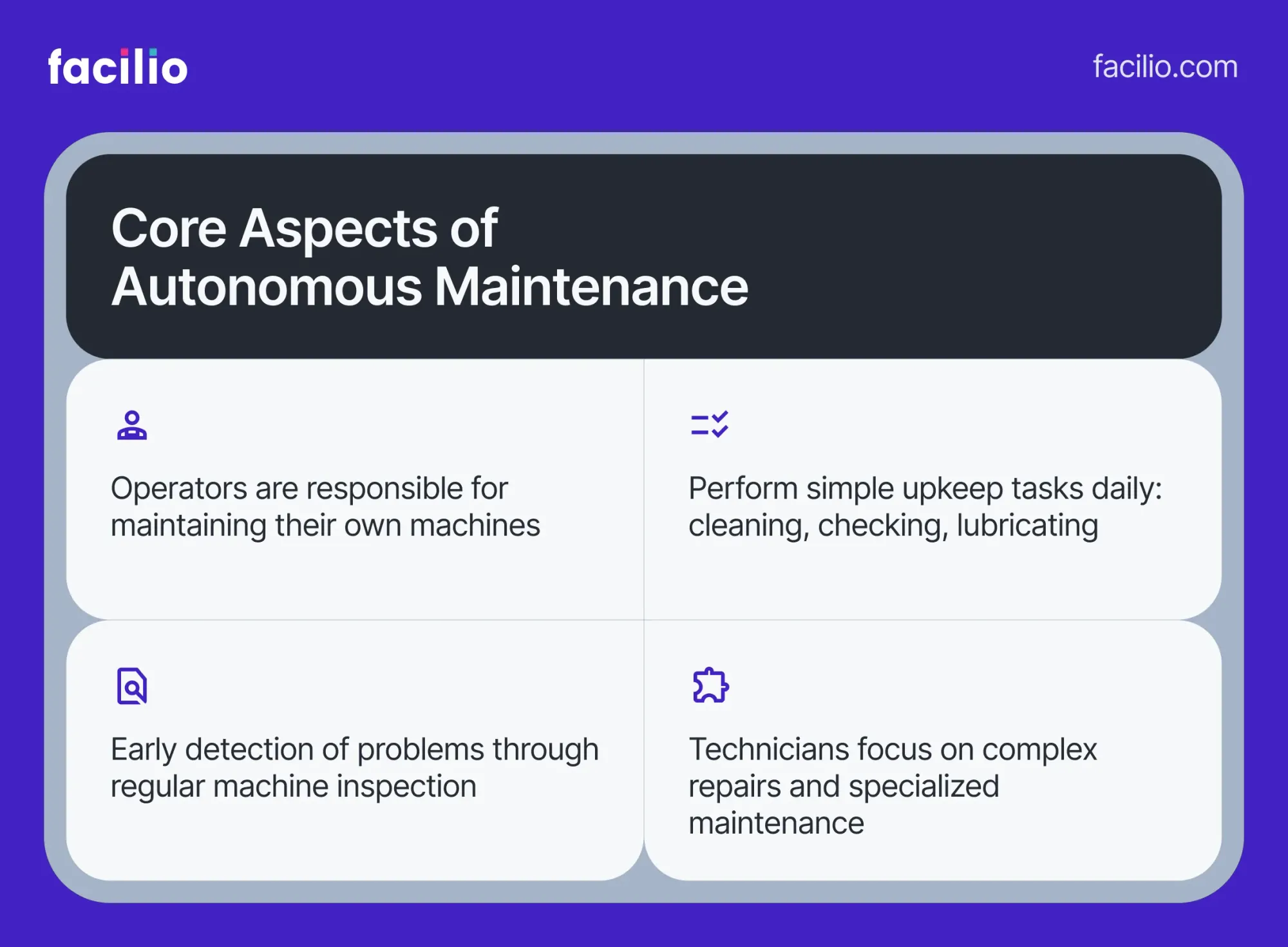

Key features of autonomous maintenance:

- Operator ownership: Operators accept responsibility for basic care and quick problem detection, creating a sense of stewardship.

- Operator training and empowerment: Structured, hands-on learning makes operators proficient in early fault detection and basic interventions.

- Preventive mindset: Rather than fix after failure, AM ensures issues are identified and addressed before they escalate.

AM is the very first and arguably most foundational, pillar of total productive maintenance, organizes all activities to maximize equipment effectiveness into eight core pillars.

They cover not only the machines but also people, processes, and culture. Autonomous maintenance (TPM AM) stands as the first and among the most crucial of these, known as the autonomous maintenance pillar.

The 8 pillars of TPM are:

- Autonomous Maintenance (AM) – Operator-driven care and accountability.

- Focused Improvement (Kobetsu Kaizen)– Systematic waste elimination and process optimization.

- Planned Maintenance – Scheduled, data-driven interventions to prevent breakdowns.

- Quality Maintenance – Defect prevention and quality assurance at the source.

- Early Equipment Management – Designing equipment for maintainability and reliability from the start.

- Training and Education – Building technical skills at all organizational levels.

- Safety, Health, and Environment – Prioritizing safe, healthy, and eco-compliant practices.

- Administration & Office – Extending best practices to office and support processes.

What is autonomous maintenance in TPM, and how does it differ from preventive maintenance?

- Autonomous maintenance assigns routine daily care (clean, inspect, lubricate) to operators, with a focus on ownership and early detection.

- Preventive maintenance is planned, interval-based work (done by technicians or engineers) focused on deeper servicing, calibrations, or part replacements

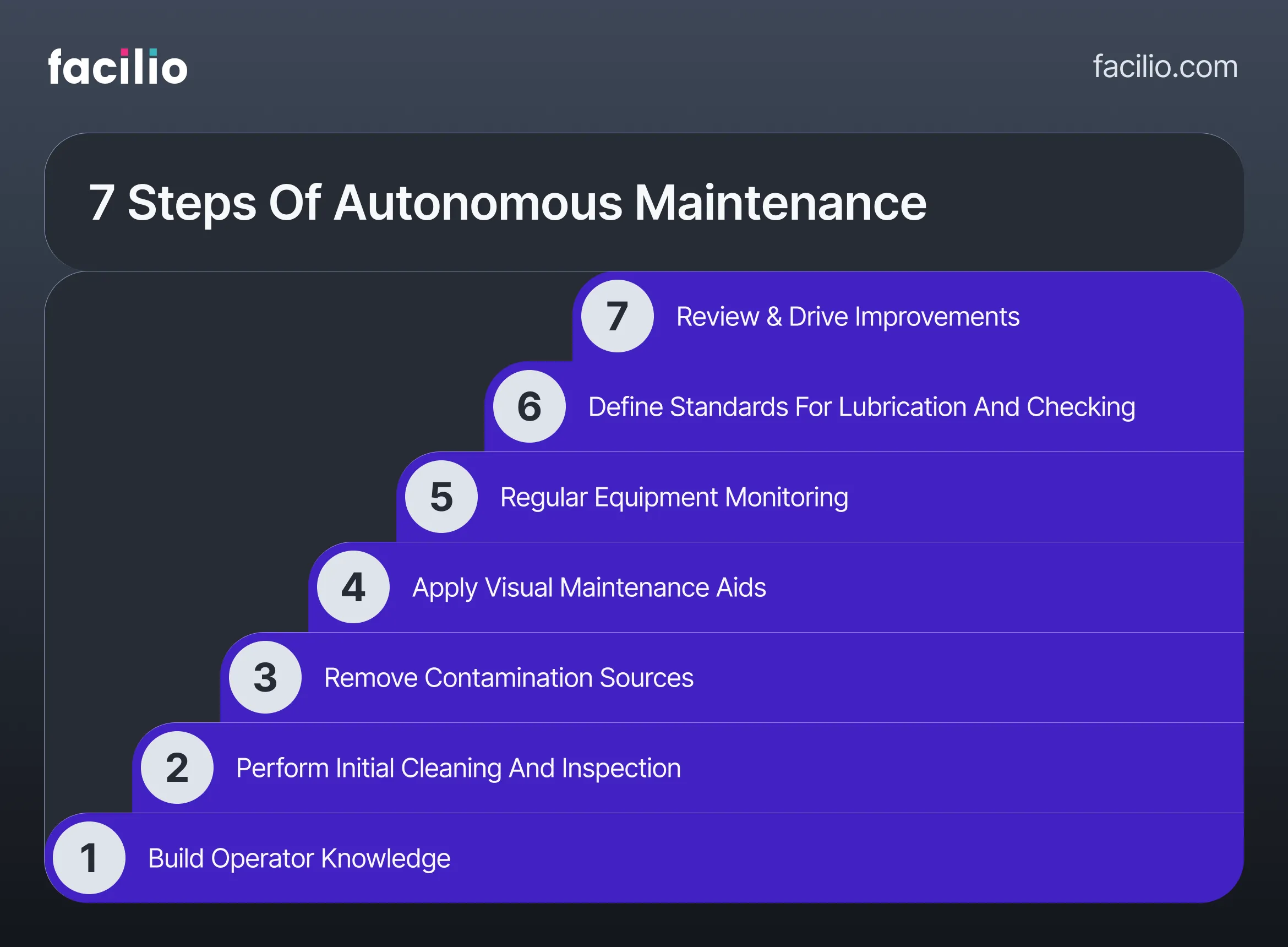

7 steps to implement autonomous maintenance

Applying autonomous maintenance varies based on the operations of each plant, but it is broken down into seven stages:

- Increasing worker knowledge and skills about equipment and its upkeep

- Perform preliminary cleanups and equipment inspections

- Check and eliminate contamination sources

- Establish contamination standards

- Conduct regular inspections

- Standardize visual maintenance procedures

- Measure results and improve strategy

Step 1: Increase worker knowledge and skills

The first step in adopting AM is to give workers information on running and maintaining machinery.

Educate operators on how the machinery interacts so they know which components require regular inspections and special attention.

Implement training tools to help employees quickly improve their knowledge and comprehend practical information.

Step 2: Preliminary cleanup and examination of equipment

Once operators understand the intricacies of the machinery, they can examine it.

They must be able to detect any mechanical component that requires dust and dirt cleaning, adjusting nuts and bolts, or even painting and greasing.

Step 3: Get rid of contamination sources

Once the machinery is cleaned and restored to optimal operational conditions, the operator must learn how to maintain it.

Maintaining appropriate housekeeping and sanitation at the workplace helps prevent contamination and ensure working environment safety.

Step 4: Establish lubrication and inspection standards

Equipment must be cleaned, lubricated, and maintained in compliance with the manufacturer's recommendations to operate with optimal quality and performance.

Establish and implement standards, tools, and strategies on maintenance activities to perform, procedures, and maintenance frequency.

Step 5: Conduct regular inspections and monitoring

Operators can check their machinery and submit inspection reports with images detailing the present state of the machinery and the maintenance chores undertaken.

This also includes routine walk-around visual inspections and the use of basic sensory tools to identify early signs of wear, leaks, or abnormalities before they escalate.

Step 6: Standardize visual maintenance

Make it simpler for operators to execute upkeep tasks by using visual information such as color-coded tags and simple signs that remind employees of the actions to take when operating the equipment or being around them.

This also includes routine walk-around visual inspections and the use of basic sensory tools to identify early signs of wear, leaks, or abnormalities before they escalate.

Step 7: Drive continuous improvement

AM is not a one-time activity you complete after meeting goals. It’s what you do during an asset’s lifetime. Continually gather and evaluate maintenance data to determine how to optimize your maintenance strategy.

Key components of autonomous maintenance

The effectiveness of AM depends on executing a few core activities consistently, these are often grouped as AM pillar steps:

- 5S Audits: Regular, structured reviews to ensure workplaces and machines are organized, clean, and ready for work.

- Abnormality Management: Swift identification, reporting, and correction of any signs of abnormal equipment behavior during routine checks.

- CILs (Clean, Inspect, Lubricate)/Centerlining: Daily or shift-based activities for keeping machines at baseline conditions and operating parameters.

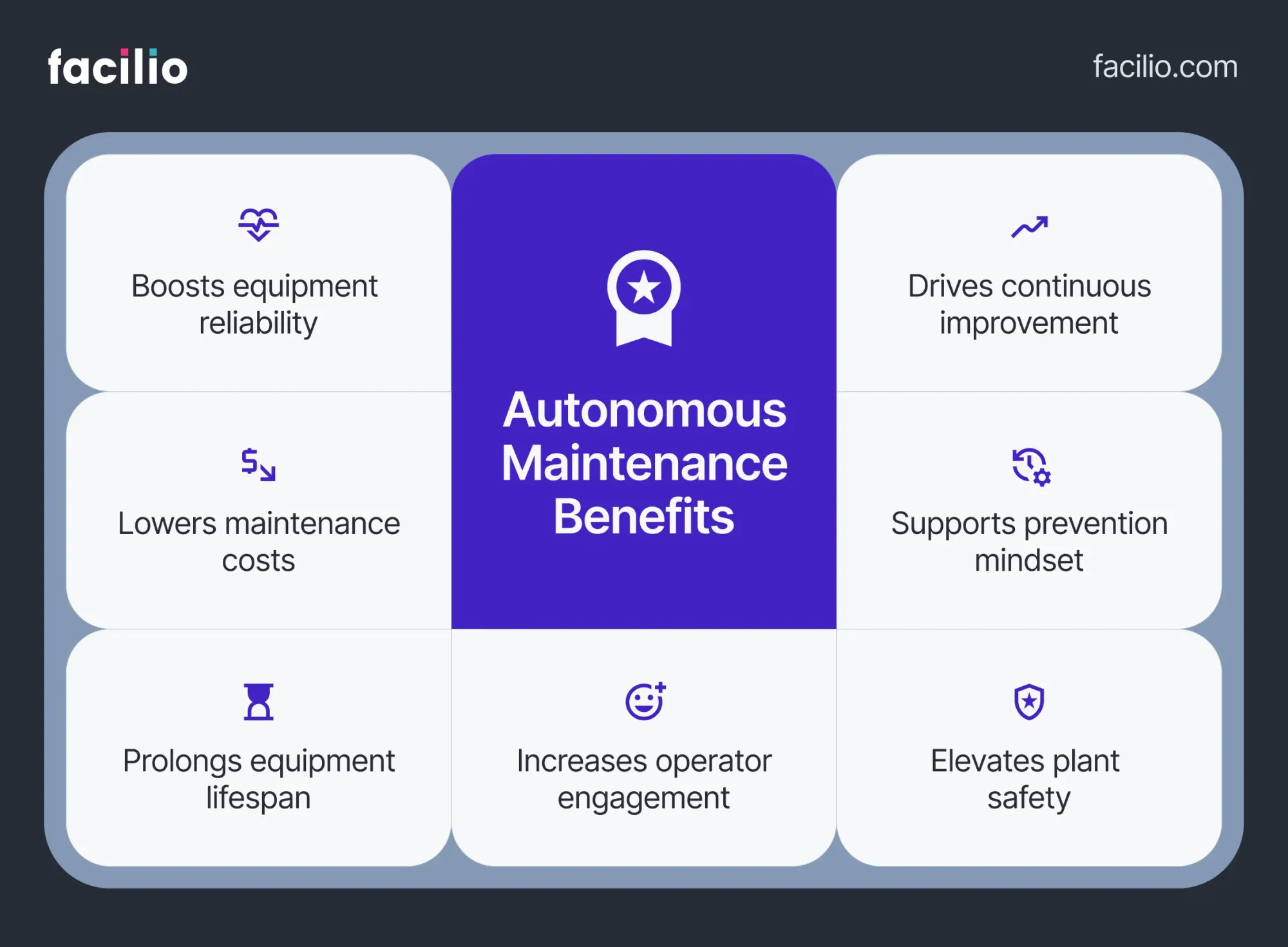

Why is autonomous maintenance important?

Autonomous maintenance training and implementation fundamentally re-shape operational results. Here’s why it matters, and what you gain:

- Boosts equipment reliability: Early detection by operators slashes unexpected failures and unplanned downtime.

- Lowers overall maintenance costs: Operators handle minor fixes and daily upkeep, freeing technicians for strategic, high-skill work.

- Prolongs equipment lifespan: Routine cleaning, lubricating, and monitoring prevent premature wear or catastrophic breakdowns.

- Increases operator engagement: Ownership equals pride, engaged operators care more for their equipment, leading to consistently superior performance.

- Elevates plant safety: Well-maintained, clutter-free equipment and areas greatly reduce accident risks.

- Supports a prevention mindset: The steps of autonomous maintenance establish a company-wide focus on anticipating and preventing issues, rather than reacting to them.

- Drives continuous improvement: Regular feedback and visible results (like reduced downtime and fewer major repairs) motivate operators and management alike.

From lean manufacturing to heavy industry, embracing AM is proven to yield measurable results, faster throughput, fewer defects, and sustained competitive advantage.

Autonomous maintenance benefits across industries

Autonomous maintenance is remarkably adaptable, with compelling use cases across manufacturing, process industries, energy, and beyond.

Manufacturing

Operators are trained to clean, inspect, and lubricate machinery, like conveyor belts and machine tools, helping reduce breakdowns and keep production lines running efficiently.

Healthcare

Technicians and staff perform basic maintenance on medical devices, including cleaning and sterilization. This ensures compliance, equipment availability, and patient safety.

Transportation

Drivers and fleet operators check tire pressure, fluid levels, and brake systems regularly. These proactive checks minimize vehicle failures and extend asset lifespan.

Energy

Facility operators at plants and refineries carry out daily checks on pipes, valves, and tanks. This prevents costly outages and maintains safe, efficient energy production.

Food and Beverage

AM practices like cleaning production lines and inspecting equipment help maintain hygiene standards and ensure consistent product quality across shifts.

Tips to sustain autonomous maintenance at scale

- Schedule refresher training: Make re-training part of onboarding and continuous improvement cycles to address turnover or knowledge drift.

- Automate reminders and audits: Use CMMS to prompt autonmous maintenance tasks and audits, flagging overdue actions before they become problems.

- Link results to improvements: Celebrate teams with the best uptime/lowest defects, reinforcing the positive impact of AM on the bottom line.

- Integrate AM into daily meetings: Briefly review AM findings and KPIs at every shift handover or operations huddle.

- Keep visual controls dynamic: Update color codes, SOPs, and checklist displays as machines or processes evolve.

Encourage operator feedback: Provide a click-drop digital platform for operators to log suggestions or report recurring pain points, and actually act on them.

How does a CMMS help with autonomous maintenance?

A CMMS helps businesses manage and optimize maintenance processes by providing a centralized system for storing and accessing maintenance schedules, documents, and data.

It lets machine operators track maintenance activities and collaborate with stakeholders to ensure that tasks are consistent and accurate.

It also tracks and analyzes maintenance data, improving the efficiency and effectiveness of autonomous maintenance efforts.

Here are some features of CMMS software that help:

- Asset Tracking – logs each machine’s maintenance history, configuration changes, and ownership within a unified repository.

- Preventive Maintenance Scheduling & Work Orders – automates reoccurring inspections and task assignments; generates work orders and audit trails.

- Inventory Management – monitors spare-part levels, automates reordering thresholds, zeroes in on cost and downtime impacts.

- Training & Compliance Tracking – confirms operator certifications and training tied to task readiness.

- Reporting & Analytics Dashboards – visualize KPI trends like OEE, MTTR, compliance rate to drive continuous improvement.

Conclusion:

Autonomous Maintenance isn’t just a maintenance upgrade—it’s a reliability revolution. By empowering operators through the full 7-step AM framework, organizations can gain measurable control over asset health, shift routine work away from technicians, and accelerate insights through CMMS-driven data.

As field experience shows, even modest OEE improvements of 5–10% compound into double‑digit ROI, 20–40% less unplanned downtime, and longer equipment lifecycles.

In short: when strategy, culture, and technology converge, CMMS‑backed AM ceases to be a program, it becomes your competitive operational backbone.

Get started now.

Let our product experts take you through our platform.

FAQs

What is autonomous maintenance and how does it work?

Autonomous maintenance is a maintenance strategy where machine operators perform routine equipment care tasks like cleaning, lubricating, and inspecting the machines they operate daily. It works by empowering frontline workers to take ownership of basic maintenance activities, allowing specialized technicians to focus on more complex repairs and preventive maintenance tasks.

What are the 7 steps of autonomous maintenance implementation?

The seven steps of autonomous maintenance include:

1) Initial cleaning to remove unnecessary items,

2) General inspection to identify abnormalities,

3) Initial lubrication following proper schedules,

4) Tightening bolts and fasteners,

5) Standardization of cleaning and inspection procedures,

6) Autonomous inspection beyond routine tasks, and

7) Continuous review and improvement of the AM process.

What is the difference between autonomous maintenance and preventive maintenance?

Autonomous maintenance assigns routine daily care tasks like cleaning, inspecting, and lubricating to operators with a focus on ownership and early detection, while preventive maintenance involves planned, interval-based work performed by technicians focused on deeper servicing, calibrations, and part replacements.

Autonomous maintenance is continuous and operator-led, whereas preventive maintenance is periodic and technician-led.

What are the main benefits of implementing autonomous maintenance?

Key benefits include preventing equipment deterioration through consistent routine care, reducing labor costs by eliminating travel time for technicians, detecting issues before they worsen, improving overall equipment effectiveness (OEE), and freeing up maintenance personnel for more critical tasks. Additional benefits include increased productivity, reduced downtime, enhanced workplace safety, and improved team cohesiveness.

How does autonomous maintenance improve overall equipment effectiveness (OEE)?

Autonomous maintenance improves OEE by maximizing machine availability through reduced breakdowns, enhancing performance through proper equipment care, and maintaining quality levels through consistent operator attention. By having operators perform routine maintenance tasks, equipment runs more reliably with fewer unplanned shutdowns, directly contributing to higher OEE scores.

What training is required for operators in autonomous maintenance programs?

Operators need training on equipment functionality, proper maintenance procedures, safety protocols, and how to identify abnormalities or potential issues. Training should be provided by experienced maintenance technicians who can teach operators which tasks are appropriate for them and which require specialized expertise, ensuring proper execution without equipment damage.

How do you start implementing an autonomous maintenance program?

Start by clearly defining roles and responsibilities, then train operators on specific maintenance tasks using experienced technicians as instructors. Begin with a pilot program on one machine to test and refine processes before full rollout, and dedicate specific time for operators to perform maintenance work in addition to their regular production duties. Develop standardized documentation for tasks, schedules, and procedures to ensure consistency and effectiveness.

More from Facilio

![5 Best Facilities Management Software for Schools [2026]](/blog/content/images/size/w600/format/webp/2024/07/Building-managementt--1-.png)