What is a work order?

A work order is a formal document—digital or paper—that outlines a specific job, detailing the task, who will do it, when it’s due, and what resources are needed.

In facilities management and maintenance, work orders keep daily operations organized, from scheduling preventive maintenance to handling urgent repairs. They ensure tasks are clear, trackable, and compliant.

A work request is simply a request for a job to be done; once approved with full details, it becomes a work order. A job order is similar but often used in manufacturing or project-based industries.

If you’re wondering “what does work order mean?”, it’s essentially the bridge between identifying a need and getting the job done—clearly, and with accountability.

Purpose of a work order: Why is it important?

Organizations use work orders to turn tasks into clear, actionable instructions. They define what needs to be done, who is responsible, the resources required, and the deadline—removing guesswork and miscommunication.

In industries like facilities management, healthcare, manufacturing, and commercial real estate (CRE), work orders are essential for:

- Task clarity – Everyone knows exactly what needs to be done

- Accountability – Assigning responsibility for each job

- Documentation – Keeping a record for audits and performance reviews

- Compliance – Meeting safety and regulatory standards

So, what is a work order used for?

It’s the operational link between identifying a job and completing it—ensuring work is organized, traceable, and done right the first time.

Common types of work orders

Not all work orders are the same; each serves a different purpose depending on the job. Here are the most common types you’ll encounter in facilities and asset management:

- Preventive maintenance work order – Scheduled tasks to keep assets in good working condition, such as quarterly HVAC servicing or monthly fire safety checks.

- Reactive maintenance work order – Unplanned jobs triggered by an issue, like repairing a leaking pipe or replacing a failed motor.

- Inspection work order – Routine checks to assess asset health, such as elevator safety inspections or electrical system reviews.

- Corrective work order – Follow-up tasks to fix issues found during inspections, like replacing worn belts on a conveyor or recalibrating a sensor.

- Special project work order – One-off or non-routine work, such as office space renovations or seasonal landscaping.

If you’re asking “what is a maintenance work order?”, it’s any of these job types applied specifically to maintaining equipment, systems, or facilities, planned or unplanned.

Work order vs. work request

Although often used interchangeably, a work order and a work request are not the same.

- Work request – A submission asking for a job to be done, usually from a tenant, employee, or monitoring system. It’s a proposal, not an instruction.

- Work order – A formal, approved document that includes all necessary details to carry out the job—scope, assignee, timeline, and resources.

Key difference: A work request identifies what needs attention, while a work order defines how and when it will be addressed.

Example:

- Work request – “Air conditioning in Meeting Room B is not cooling.”

- Work order – “Replace air conditioning unit in Meeting Room B; assign to HVAC technician; priority: high; completion by 5 Aug 2025.”

If you’re wondering “what is a work order request?”, it refers to the initial request form or system entry that starts the process before approval turns it into a formal work order.

Benefits of using work orders

A well-structured facilities work order system does more than assign jobs—it creates a foundation for consistent, measurable, and compliant operations.

- Centralized task tracking – Every job, from preventive maintenance to urgent repairs, is recorded in a single system. This makes it easier to manage workloads, avoid duplication, and monitor progress in real time.

- Clear accountability – Work orders name the responsible technician or contractor, define the scope, and set deadlines. This reduces confusion, ensures ownership, and improves follow-through.

- Compliance documentation – In regulated industries, proving that maintenance was completed on time and to standard is essential. Work orders create an audit-ready history that supports safety inspections, environmental audits, and quality certifications.

- Historical data for planning and budgeting – By analyzing past work orders, teams can identify recurring issues, calculate asset lifecycle costs, and justify budget requests. For example, a year’s worth of HVAC work orders might reveal the need for equipment replacement rather than continued reactive repairs.

In practice, a strong work order process helps facilities teams stay proactive, reduce downtime, and make better decisions based on accurate, accessible data.

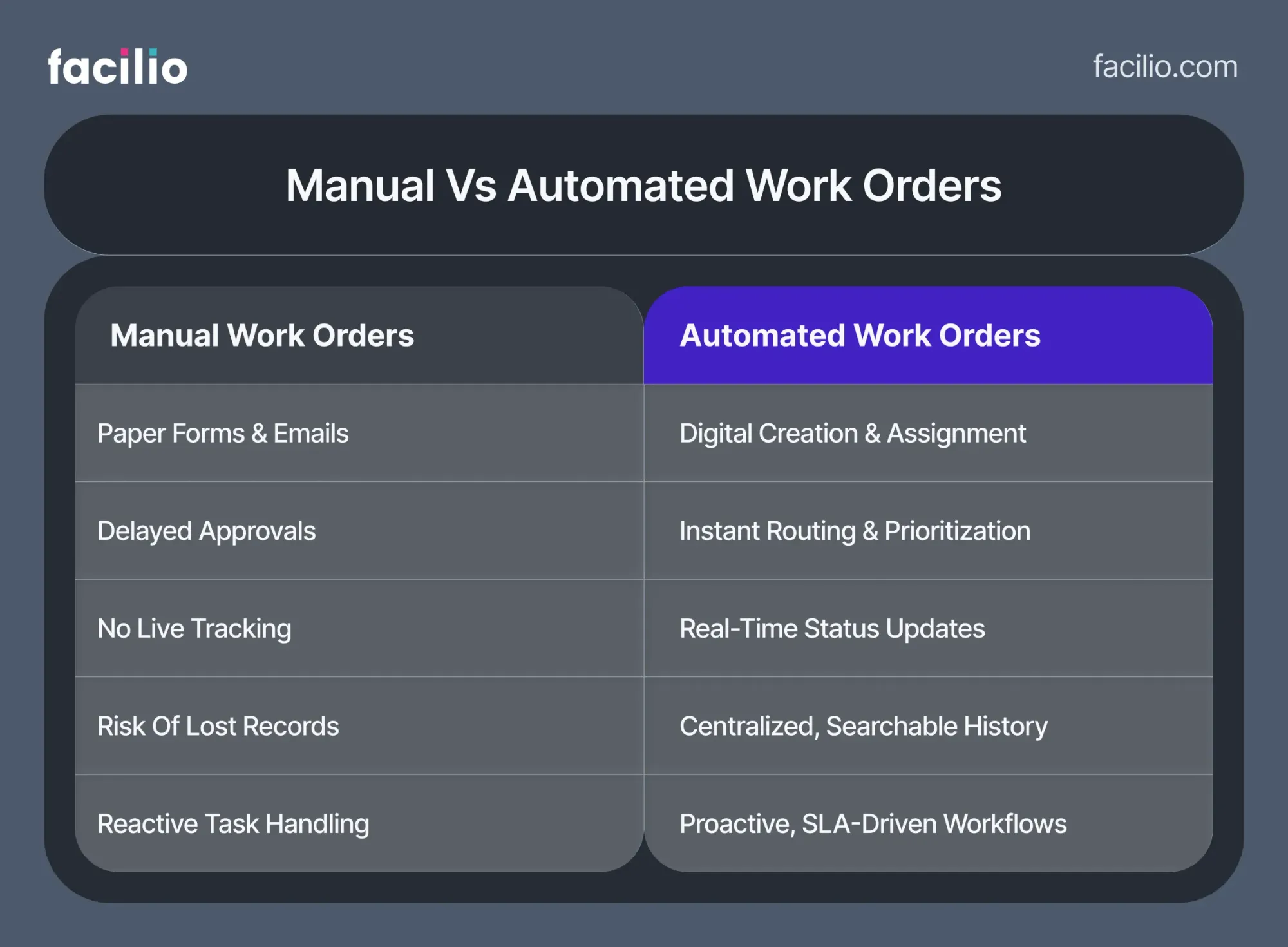

Common challenges with manual work orders

While paper forms, spreadsheets, or email-based work orders may seem manageable, they often create bottlenecks that slow down operations and increase costs. Common issues include:

- Lost paperwork or incomplete records – Physical work orders can be misplaced, and missing details make it harder to track what was done, when, and by whom.

- Delayed approvals and job starts – Approvals that rely on physical signatures or back-and-forth emails can push urgent work days behind schedule.

- Lack of visibility on status and progress – Without a centralized system, managers can’t see in real time which jobs are in progress, pending, or overdue.

- Miscommunication between stakeholders – Details can be misunderstood when information passes through multiple channels, leading to rework or missed steps.

- Inefficient prioritization – Without automation or clear data, low-priority jobs might be handled before critical ones, risking compliance or operational continuity.

These challenges make it difficult for facilities teams to work efficiently—especially across multiple sites—setting the stage for why many organizations turn to automated and connected solutions.

Introduction to automated work orders

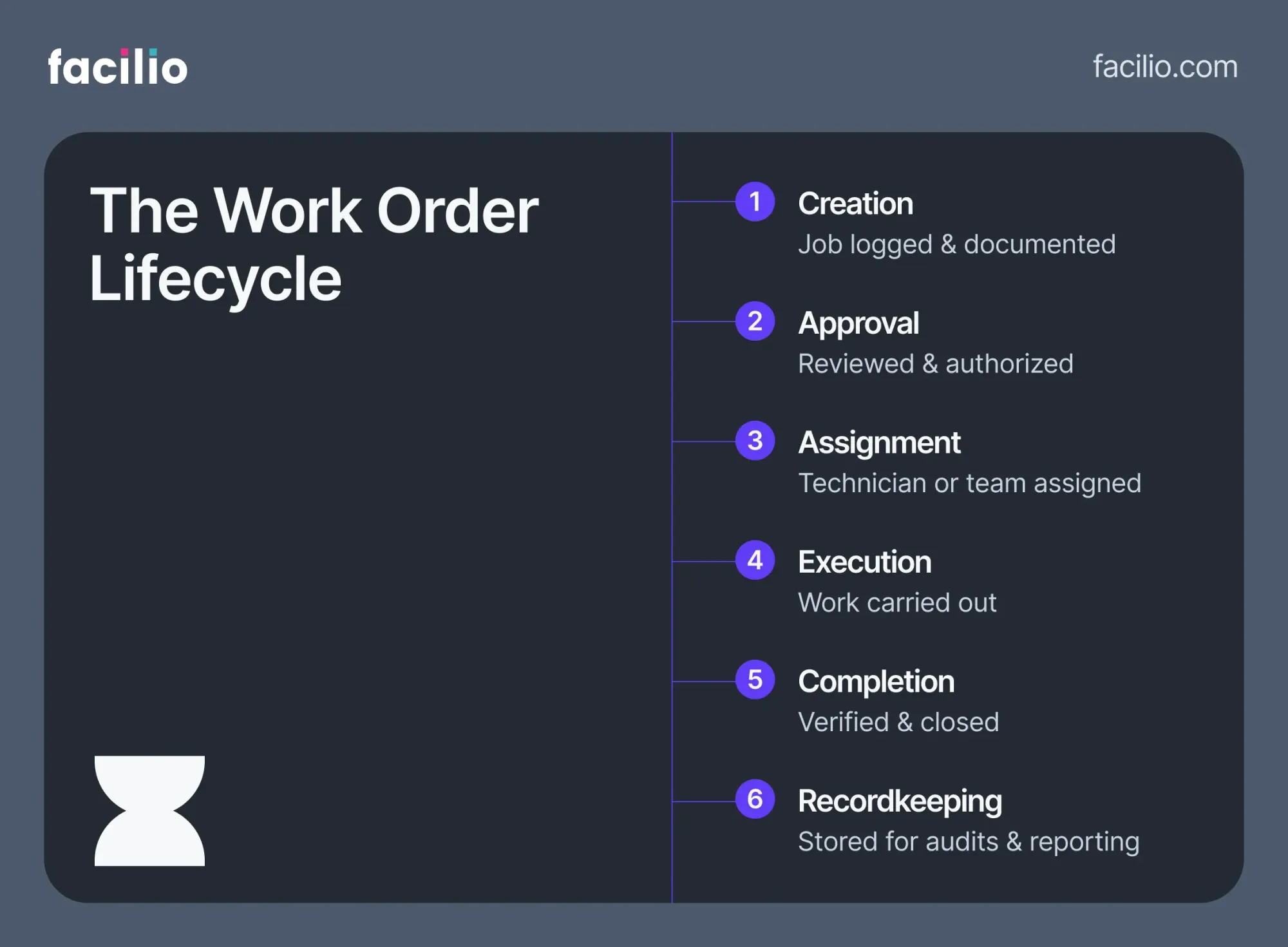

An automated work order uses technology—typically a CMMS (Computerized Maintenance Management System)—to create, assign, track, and close jobs without the delays and errors of manual processes.

Instead of filling out paper forms or relying on email chains, automated systems trigger work orders based on set conditions: a scheduled maintenance date, a sensor alert, or a submitted work request. The system then routes the job to the right technician, sets deadlines, and tracks progress in real time.

For facilities, healthcare, manufacturing, and other asset-intensive industries, automation ensures that urgent repairs are handled quickly, preventive tasks aren’t overlooked, and all activity is recorded for compliance and reporting.

By removing manual bottlenecks, automated work orders make operations faster, more accurate, and easier to manage—especially across large or multi-site portfolios.

Key benefits of automated work orders

Switching from manual processes to automated work orders delivers clear operational gains:

- Faster turnaround – Jobs are assigned instantly, cutting approval and scheduling delays.

- Reduced errors – Pre-filled templates and standardized workflows remove guesswork and prevent missing details.

- Better prioritization – Automated rules ensure critical tasks are handled first based on SLA requirements, asset criticality, or safety impact.

- Real-time visibility – Managers can track progress live, reassign work when needed, and receive instant status updates.

- Integrated workflows – Links with inventory, asset data, and vendor information to ensure technicians have everything needed to complete the job.

- Stronger compliance – Every step is logged automatically, creating an audit-ready record for inspections and certifications.

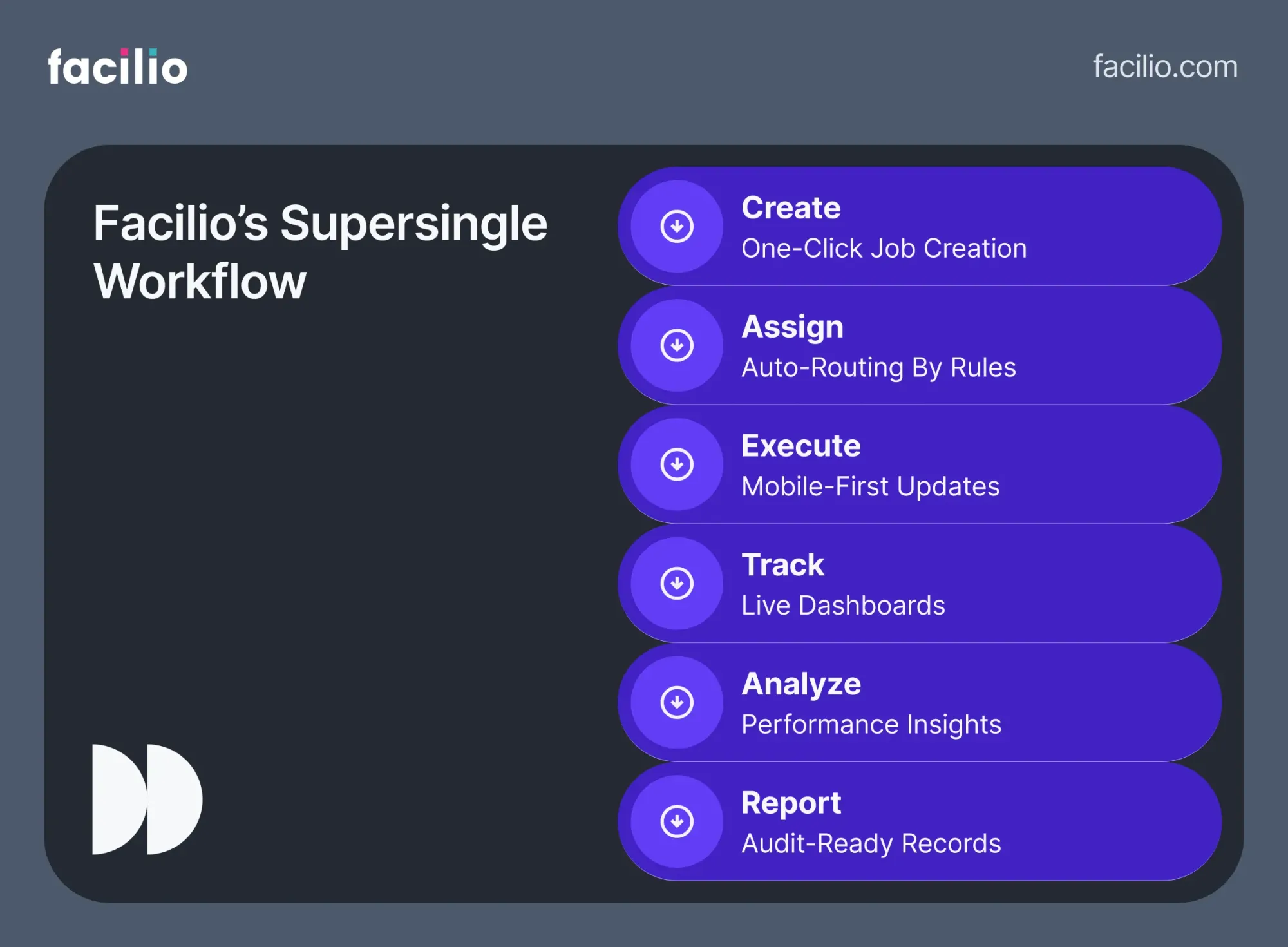

One connected platform. Every work order. Zero inefficiency.

Most platforms claim to simplify work order management, but in reality they only digitize existing silos.

Approvals still lag in email chains, updates get lost between systems, and managers spend hours chasing status reports.

Facilio’s Connected CMMS changes the game with a supersingle work order management flow — every step, from creation to compliance reporting, happens in one platform.

No juggling tools, no duplicate data entry, no blind spots.

Key advantages of Facilio’s Connected CMMS in work order management

- One platform for every job – Create, approve, assign, and close work orders across all sites from a single dashboard.

- Mobile-first execution – Field teams update job status, attach photos, and log time instantly from any device.

- Smart routing & prioritization – Automatically assigns tasks based on SLA rules, asset health, and technician capacity.

- Integration without disruption – Works seamlessly with your existing BMS, ERP, and IoT systems.

- Data-driven decision-making – Turns historical work order trends into insights for preventive planning and budget optimization.

- Audit-ready compliance – Keeps a complete, timestamped record for inspections and certifications.

With Facilio, every work order becomes part of a connected, intelligent process that reduces turnaround times, improves accountability, and drives better maintenance outcomes at scale.

Whether you’re managing one facility or hundreds, it’s the fastest way to move from task chaos to operational clarity.