Unseen leaks aren’t just a maintenance issue—they’re a million-dollar blind spot.

In the United States, fugitive emissions from industrial equipment account for over 70 million metric tons of CO₂-equivalent greenhouse gases annually, according to the EPA.

These emissions often come from hard-to-detect leaks in valves, pumps, connectors, and compressors—leading to massive product losses, serious regulatory fines, and reputational risks.

That’s where Leak Detection and Repair (LDAR) programs become critical—not just as a compliance checkbox, but as a strategic, bottom-line-saving investment.

For facility managers, EH&S professionals, and maintenance leaders, LDAR is no longer optional. It’s a regulatory expectation under federal rules like 40 CFR Parts 60, 61, and 63, and a proactive tool to meet ESG goals, reduce insurance liabilities, and ensure workplace safety.

In this guide, we’ll walk through:

- What LDAR means in today’s regulatory and operational landscape

- Proven detection technologies and how to choose the right one

- Compliance pitfalls to avoid

- Best practices from top-performing facilities in the US

- And practical tips to build an efficient LDAR program that delivers ROI

Whether you're scaling your current program or building one from scratch, this guide will help you master the nuances of LDAR—and future-proof your operations.

What is Leak Detection and Repair (LDAR)?

LDAR—short for Leak Detection and Repair—is a program used by industrial facilities to find and fix leaks in equipment that handles hazardous gases and liquids.

Leaks tend to occur in high-risk components like valves, pumps, connectors, compressors, and agitators—especially in sectors like petrochemical, refining, chemical manufacturing, and natural gas processing. Left unchecked, these leaks release volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) into the atmosphere, harming both people and the planet.

But LDAR is more than environmental goodwill—its risk mitigation meets operational discipline.

Why LDAR Matters

Here’s what a well-run LDAR program achieves:

- ✅ Reduces fugitive emissions that contribute to smog and health hazards

- ✅ Prevents regulatory penalties under Clean Air Act regulations (40 CFR Part 60, 61, 63

- ✅ Improves equipment reliability, reducing unscheduled downtime

- ✅ Boosts worker safety by eliminating exposure to flammable/toxic gases

- ✅ Protects your bottom line—some leaks can cost tens of thousands per year in lost product

A single leaking valve can release over 10,000 ppm of VOCs—well above the EPA’s leak threshold. Without LDAR, these leaks often go undetected for months.

How LDAR Works (In Practice)

LDAR programs are not just about finding leaks—they’re about creating a repeatable, verifiable process that ensures leaks are identified, fixed, and documented to meet regulatory and operational standards.

Here's a breakdown of how an effective LDAR program runs on the ground.

1. Routine Inspections: Finding the Invisible

Regular inspections are the backbone of any LDAR program. Depending on the regulation and risk profile, these inspections can happen monthly, quarterly, or semi-annually. Trained technicians use specialized tools such as:

- Flame Ionization Detectors (FID) and Photoionization Detectors (PID) to measure VOC concentrations

- Optical Gas Imaging (OGI) cameras are effective in visually detecting gas leaks, especially in high-risk areas and large facilities

- Ultrasonic leak detectors for pressurized gas systems

2. Leak Quantification: Measuring What Matters

Once a leak is detected, it needs to be quantified to assess its severity and prioritize response. Typically, leak rates are measured in:

- Parts per million (ppm) of VOC concentration

- Mass emissions rate (e.g., pounds/hour or kg/hour), calculated using EPA’s Method 21 or Method 22

Thresholds vary based on equipment type and industry. For example, under 40 CFR Part 60 Subpart VV, leaks above 10,000 ppm from valves require prompt repair.

3. Tagging and Documentation: Creating a Paper Trail

Every leak must be tagged—physically (with a label or barcode) and digitally. Proper documentation includes:

- Equipment ID

- Location

- Component type

- Date/time of detection

- Leak concentration

Many facilities now use mobile LDAR apps that sync with centralized databases, eliminating the delays and errors common with manual logs.

4. Prioritization and Repair: Fixing Smart, Not Just Fast

Not all leaks carry the same urgency. Repairs are typically prioritized by:

- Severity of emissions

- Location (proximity to personnel or ignition sources)

- Regulatory deadlines (often within 5–15 days of detection)

Facilities often implement a first-fix philosophy: if a component can be repaired during inspection without a shutdown, it’s done immediately. Otherwise, it’s scheduled during planned downtime.

5. Re-Monitoring: Trust, But Verify

Once a repair is made, a follow-up inspection must confirm that emissions have dropped below regulatory thresholds. This is typically performed using the same method used during detection to maintain consistency.

If the leak persists, it must be repaired again or documented under "delay of repair" provisions, which are only allowed under strict conditions (e.g., shutdown required).

6. Reporting & Recordkeeping: Staying Audit-Ready

Compliance doesn’t end with fixing the leak. Detailed reports must be compiled for:

- Regulatory agencies (EPA, state-level air quality boards)

- Internal audits

- Third-party verifications for ESG reporting

Failing to maintain proper LDAR records is one of the top EPA citation triggers—even more than the leaks themselves.

Required records often include:

- Monitoring logs

- Repair timelines

- Calibration records of detection instruments

- Annual LDAR reports

Facilities that leverage LDAR software platforms (like LeakDAS, Guideware, or custom CMMS integrations) can easily pull up records during audits and avoid costly penalties.

Leak Detected → Leak Quantified → Tagged → Logged → Prioritized → Repaired → Verified → Reported

Want to automate every step of this process—from detection to documentation?

Talk to an expertWhy is LDAR Important in the US?

In the US, LDAR isn’t just good practice—it’s a critical necessity.

Here’s why:

1. It Protects the Environment—and Your Reputation

Industrial facilities release tons of VOCs (Volatile Organic Compounds) and HAPs (Hazardous Air Pollutants) every year through equipment leaks. These emissions contribute to:

- Smog and poor air quality

- Ozone layer depletion

- Climate change

According to the EPA, fugitive emissions can account for up to 60% of total VOC emissions in some facilities. LDAR helps cut these emissions by 40–70%, depending on how rigorous your program is.

2. It Keeps You Compliant and Audit-Ready

US industries must follow strict EPA mandates—notably 40 CFR Parts 60, 61, and 63, and Method 21, which sets detection limits and monitoring protocols.

Non-compliance isn’t cheap. Fines can reach $37,500+ per violation, per day—and that’s just federal. State regulations can be just as demanding.

✅ What Smart Facilities Do: They run mock audits and digitize their LDAR data to avoid surprises during EPA inspections.

3. It Saves You Real Money

LDAR isn’t just a compliance expense—it’s a cost-saving investment. Here’s how:

- Reduces product loss by detecting leaks early

- Lowers maintenance costs by preventing breakdowns

- Avoids unplanned shutdowns and associated downtime

Studies show that LDAR programs can save $500,000–$730,000 annually per facility. In some cases, the ROI on LDAR can be achieved within 6–12 months.

4. It Keeps People Safe

Leaks aren’t just an environmental issue—they’re a serious health and safety hazard. Many VOCs and HAPs are toxic or flammable, and exposure can cause respiratory issues, neurological damage, or even explosions.

Implementing LDAR helps:

- Detect dangerous leaks before they escalate

- Reduce the risk of fires and workplace injuries

- Build a culture of safety and compliance

Bottom Line

Whether you're in oil & gas, chemicals, or manufacturing, LDAR is your front line of defense. It helps you:

- Stay compliant

- Cut losses

- Protect your people

- Prove your commitment to sustainability

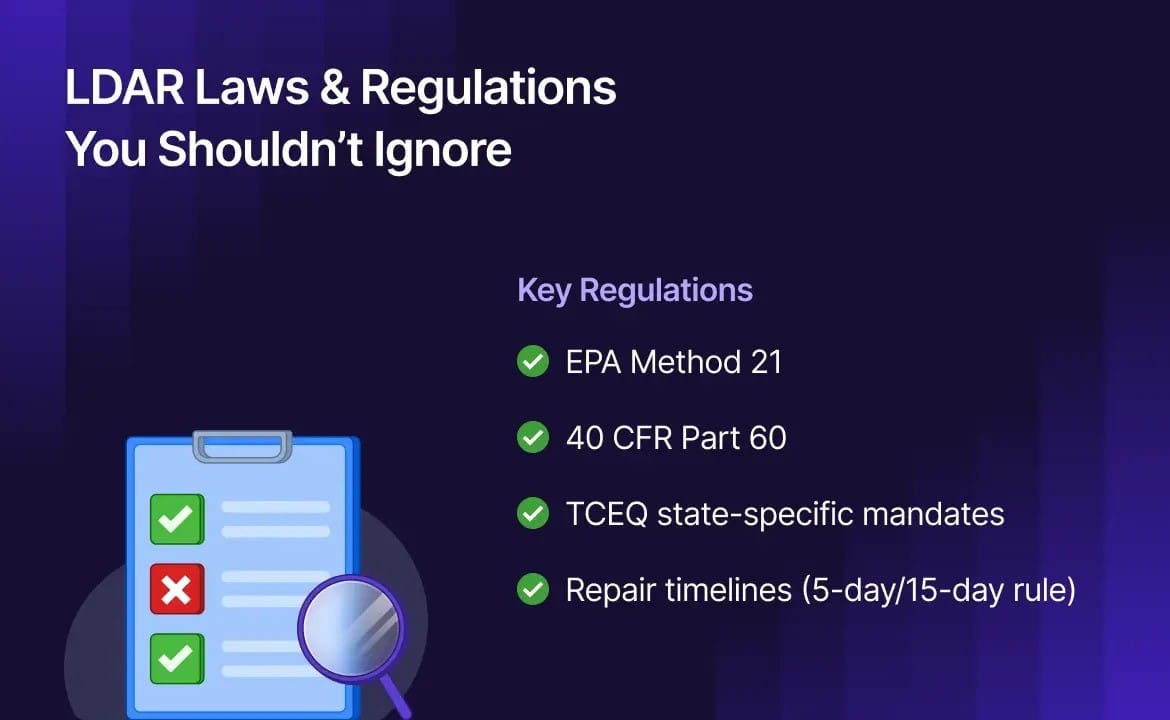

What are the regulatory frameworks for LDAR in the US?

LDAR programs in the United States aren’t optional—they’re backed by a solid wall of federal and state regulations. These laws are designed to hold industrial facilities accountable for their emissions and ensure proper monitoring, repair, and reporting of leaks.

A) Federal Regulations (EPA-Mandated)

The Environmental Protection Agency (EPA) sets the baseline standards all facilities must follow:

- EPA Method 21

This is the gold standard for detecting leaks. It defines how to use portable analyzers to identify VOC (Volatile Organic Compound) emissions, including calibration techniques, monitoring frequency, and detection thresholds. - 40 CFR Part 60, 61, and 63

These are the New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP). They apply to industries such as petroleum refineries, chemical plants, and natural gas processing units, requiring systematic leak monitoring and timely repairs.

Many facilities must perform leak inspections monthly or quarterly, depending on equipment type and emission levels.

B) State-Level LDAR Requirements

In addition to federal laws, individual states often impose stricter rules, especially in high-risk zones.

- Texas Commission on Environmental Quality (TCEQ)

Texas, being a hub for oil and gas, enforces detailed LDAR protocols through permits that require aggressive emission controls and reporting. Facilities must follow TCEQ’s Fugitive Emissions Guidance for equipment-specific practices. - California Air Resources Board (CARB)

California has some of the toughest emission laws in the country, often going beyond federal requirements. CARB regulations demand more frequent monitoring and comprehensive documentation.

📋 How to Stay Compliant? (Compliance Requirements)

Staying compliant isn’t just about detecting leaks—it’s about documenting every step:

- Detailed Recordkeeping

Maintain logs of every inspection, leak found, repair date, and analyzer reading. These records must be readily available for EPA or state audits, often going back 2–5 years. - Timely Repairs

You must attempt a repair within 5 days of leak detection, and complete it within 15 days—unless the component is placed on a Delay of Repair list with a valid justification (e.g., needing shutdown to fix). - Regular Audits

Internal reviews, third-party inspections, and EPA audits are standard. Facilities often perform annual audits to ensure LDAR compliance is airtight.

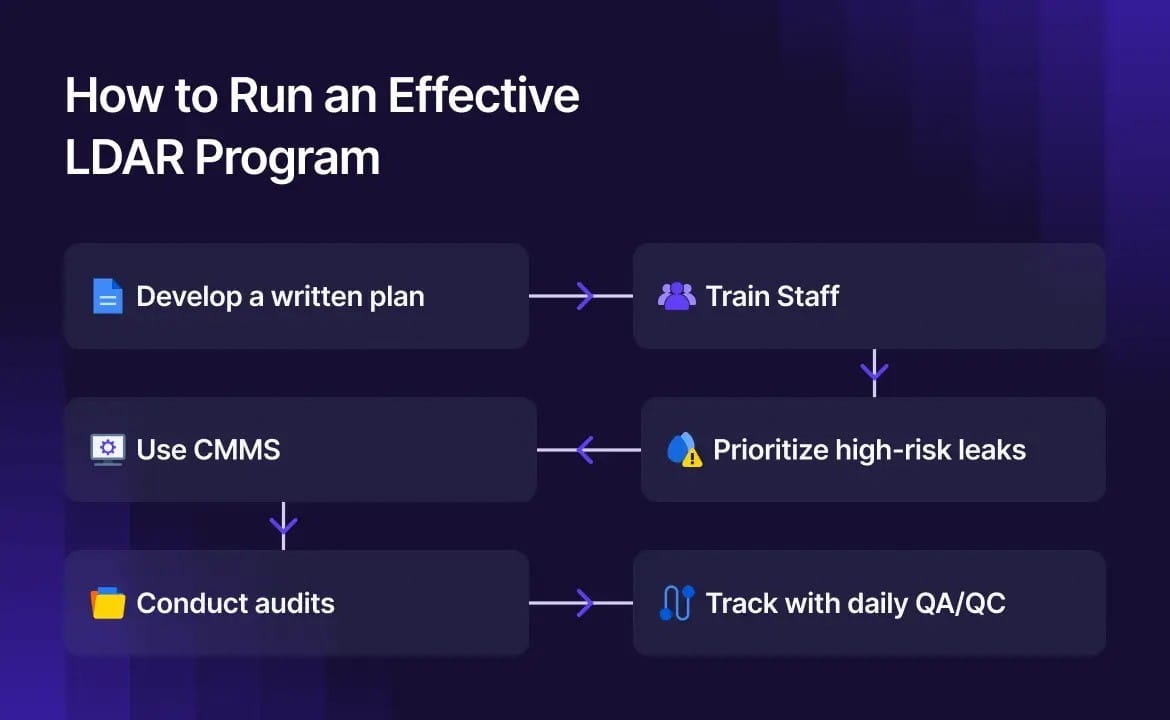

Best Practices for Implementing an LDAR Program

To make LDAR more than just a checkbox for compliance, facilities need to approach it strategically.

Here are the key best practices that transform LDAR from a regulatory burden into a performance and safety advantage:

1. Build a Structured Program

✔️ Document Everything

Start with a written LDAR plan that outlines your program’s goals, scope, equipment lists, leak definitions, monitoring frequency, and reporting protocols.

Don’t just aim for compliance—set measurable goals like “reduce VOC emissions by 30% in 12 months.”

✔️ Train Your Team Right

LDAR technicians should receive in-depth training not only on detection technologies (like flame ionization detectors and optical gas imaging) but also on safety procedures, EPA regulations, and your facility’s specific equipment layout.

2. Prioritize Leak Management

✔️ Rank Leaks by Risk

Not all leaks are created equal. Use a risk matrix to prioritize repairs—factoring in the proximity to high-pressure systems, toxic chemicals, or ignition sources. Tackling high-risk leaks first prevents safety incidents and regulatory penalties.

✔️ Maintain a Delay of Repair (DOR) Log

Some repairs require shutdowns or specialized parts. Keep a well-documented DOR list with valid justifications, estimated repair dates, and mitigation measures.

🧯 Example: If a compressor seal leak can't be fixed immediately, increase monitoring frequency or install temporary containment.

3. Make Data Work for You

✔️ Integrate with CMMS

Connect your LDAR program to a Computerized Maintenance Management System (CMMS). This helps track leaks, repair status, technician performance, and costs in real-time—plus it simplifies compliance reporting.

✔️ Go Paperless (and Smart)

Use mobile apps or tablets during field inspections to capture leak data instantly, take photos, and sync records with cloud storage. This ensures clean, time-stamped data for EPA audits or internal reviews.

4. Emphasize Quality Control and Auditing

✔️ Daily QA/QC Reviews

Have a system in place for daily review of detection logs, equipment readings, and technician notes. Catching anomalies early prevents misreporting and missed repairs.

✔️ Conduct Scheduled Audits

Run both internal and third-party audits annually or biannually to assess program performance. Look for gaps in inspection frequency, data integrity, and response time.

An LDAR program is only as good as the consistency with which it’s executed. When teams embrace these best practices—from training and prioritization to digital data handling—they move from basic compliance to operational excellence.

Why LDAR in Refrigeration Can’t Be an Afterthought

In refrigeration-heavy industries, leaks aren’t just a maintenance issue — they’re a legal, environmental, and financial risk. Harmful refrigerants like HFCs are potent greenhouse gases, and under EPA regulations, even a single undetected leak could cost you up to $57,617 per violation. But with a strong LDAR program, you’re not just staying compliant — you could cut refrigerant emissions by up to 60% in year one and save thousands in product recovery and avoid fines.

How Facilio Takes LDAR to the Next Level

Facilio’s Connected Refrigeration Management Software goes beyond basic leak detection. It automates compliance with EPA Section 608 and the AIM Act, leveraging AI to catch leaks early, before they become liabilities.

Real-time alerts, smart repair prioritization, and seamless integration with ultrasonic detectors and sensors give you pinpoint accuracy across every location.

And it’s all backed by audit-ready reporting, so you’re never scrambling during inspections.

Facilio is where compliance meets cost-efficiency

From mobile-enabled inspections to automated repair workflows, Facilio helps your teams stay on top of leak management — whether it’s internal techs or third-party contractors.

With cloud-based Fault Detection and Diagnostics (FDD) and compliance workflows trusted by over 300 sites in the US, Facilio helps you align with GreenChill, ESG, and sustainability goals without adding operational overhead.

Ready to Future-Proof Your LDAR Strategy?

Facilio helps you catch leaks earlier, stay compliant automatically, and operate more sustainably across every site.

Book a demo today and see how effortless LDAR compliance can be.

Don’t let invisible leaks drain your revenue or reputation.

Schedule Your Facilio Demo Now