Boost Campus Safety & Efficiency with Planned Preventive Maintenance (PPM)

Running a bustling university campus is no walk in the park. You've got academics, extracurriculars, sports, and a million other things to keep track of. And behind the scenes, a dedicated team of maintenance professionals is working tirelessly to ensure everything from the lights to the labs functions flawlessly.

However, many campuses rely on a "fix-it-when-it-breaks" approach to maintenance, which is like trying to put out fires instead of preventing them in the first place. While this may seem efficient in the short term, it can lead to a cycle of costly disruptions, safety risks, and inefficient processes. To create a truly safe, productive, and comfortable environment, a proactive approach to maintenance is essential. That's where planned preventive maintenance (PPM) comes in.

Why proactive maintenance is a non-negotiable for campuses

Think about it. A critical HVAC system malfunctions in the middle of a lecture, leaving students uncomfortable. A fire alarm system malfunctions, throwing the entire campus into chaos. These situations are more than just inconvenient—they disrupt classes, events, and daily operations, leading to frustration and lost learning time.

Beyond the inconvenience, a malfunctioning system can be a safety hazard, putting students, faculty, and staff at risk. And let’s not forget about the financial burden. Emergency repairs are expensive, often requiring after-hours service calls and potentially leading to further damage and more costly repairs.

Instead of focusing on proactive maintenance, your team is constantly responding to emergencies, leading to a reactive cycle of stress and rushed repairs. The key to creating a safer, more efficient, and cost-effective campus lies in shifting from a reactive approach to a proactive one.

This means embracing planned preventive maintenance (PPM) for your campus operations and ensuring that issues are addressed before they escalate.

Suggested read: The future of reactive maintenance

The inefficiency trap: why manual PPM is no longer sustainable

Let's say you've got a PPM plan in place, but things still aren't running as smoothly as you'd like. The problem could be that you're relying on manual processes and siloed systems.

Spreadsheets get lost, emails get buried, and it's tough to keep track of everything, especially when you're dealing with a lot of different buildings and equipment. This can lead to mistakes, missed tasks, and a lot of wasted time and effort.

It's like trying to manage a complex project with only a pen and paper—you might get the job done, but it's going to be a lot more difficult and stressful than it needs to be.

To implement a truly effective PPM program that boosts your campus productivity, you need a connected approach.

Benefits of a connected CMMS for campus PPM

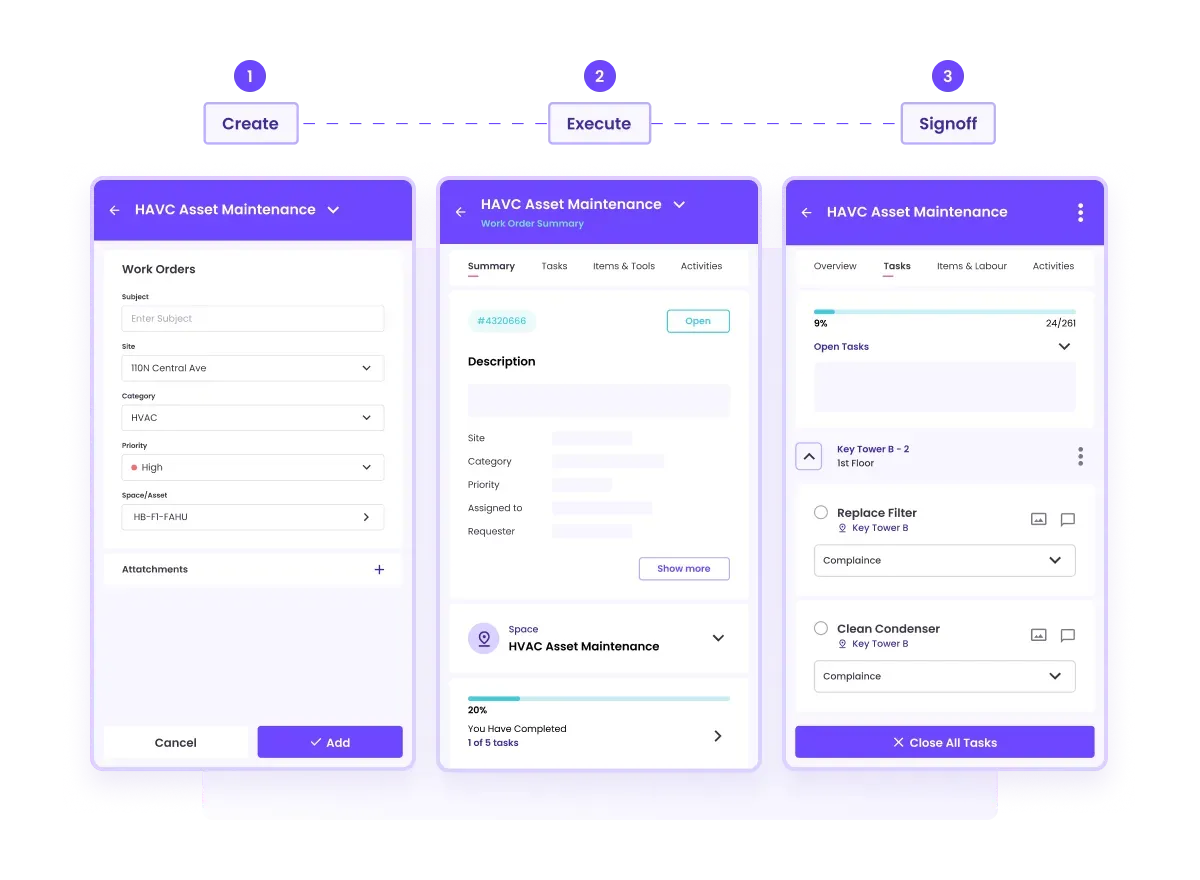

A connected CMMS takes your PPM strategy to the next level by automating the entire maintenance process, reducing the need for manual intervention, and ensuring that tasks are completed accurately.

It ensures that maintenance tasks are performed on time, every time and that potential issues are identified and addressed before they become major problems. With a connected CMMS, you can run PPM on autopilot, freeing up your team to focus on strategic initiatives rather than being bogged down by routine maintenance.

A campus where classrooms are always comfortable, labs are always ready to go, and everyone can focus on their studies, and research can sound like a dream. But with the power of a strong connected CMMS, it’s not a far-fetched idea.

Essential CMMS features for a robust PPM program

A modern CMMS solution should be highly configurable, allowing you to customize the system to meet the unique needs of your campus. When choosing a CMMS to support a strong Preventive Maintenance (PPM) program, look out for these key features:

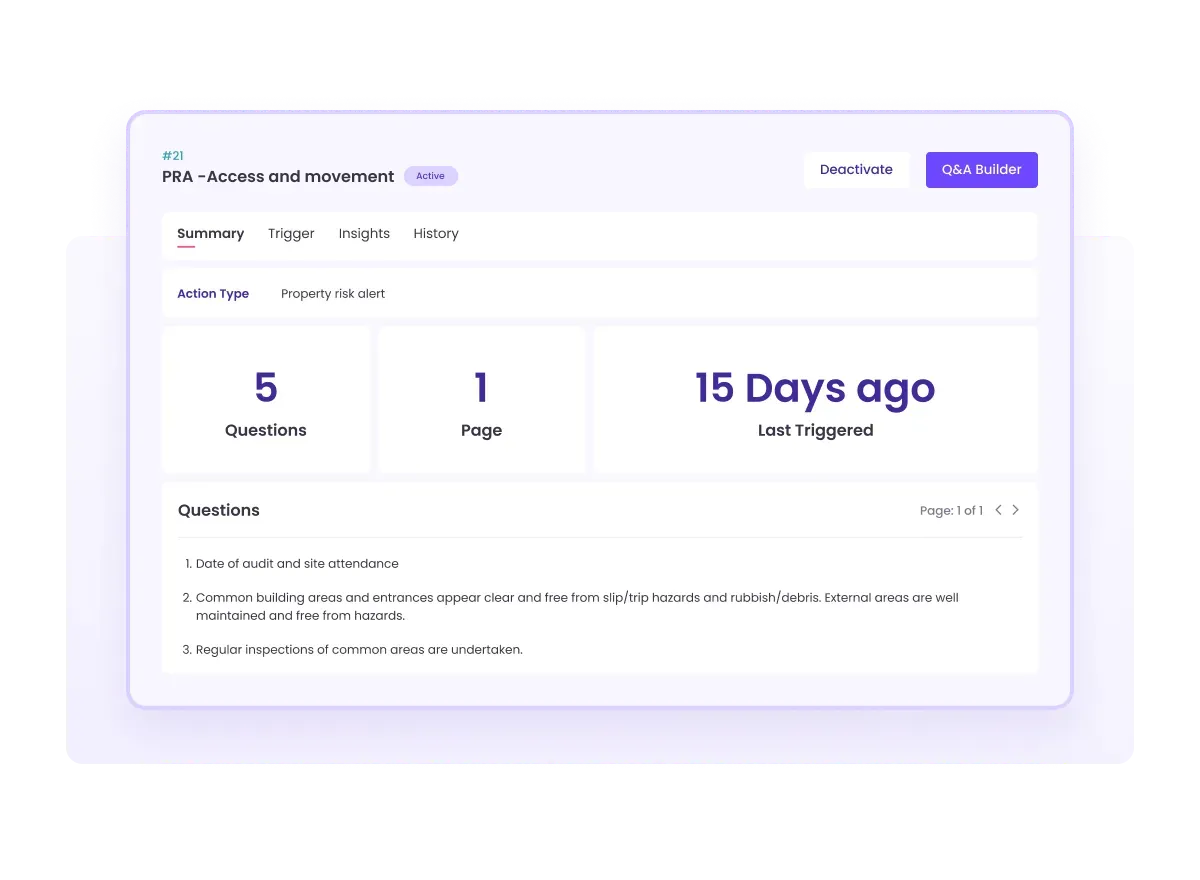

Comprehensive checks, verifications, and SLAs

Are you still using manual logs or outdated systems to manage your preventive maintenance tasks? These methods can be inefficient and lead to missed details and incomplete records.

You need a CMMS that lets you create detailed checklists, verifications, and SLA monitoring for each work order.

If your institute requires regular inspections of the fire alarm system, the CMMS can help set up a comprehensive checklist that ensures all necessary steps are completed: testing alarm sound levels, verifying smoke detector functionality, and documenting any issues.

The system also records all pertinent details and tracks the completion time to ensure adherence to SLAs. This guarantees timely maintenance and creates a complete, accessible record for compliance purposes.

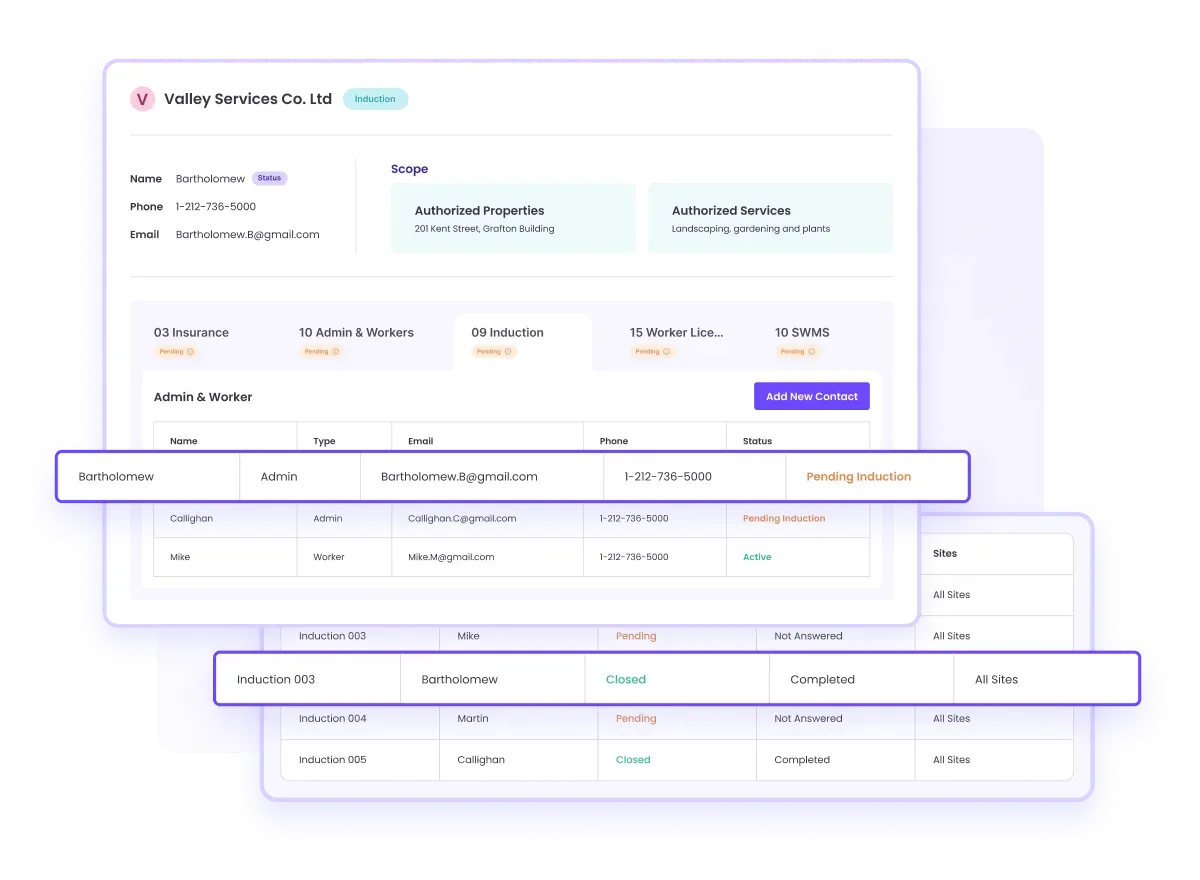

Connected CMMS streamlines the PPM processes by collecting and verifying everything from vendor qualifications and work history to licenses and insurance. Need to check if a vendor's license is up to date? The system not only stores these details but also tracks their validity. This means you’re always working with qualified, compliant vendors.

Learn about the full scope of integrated vendor management here.

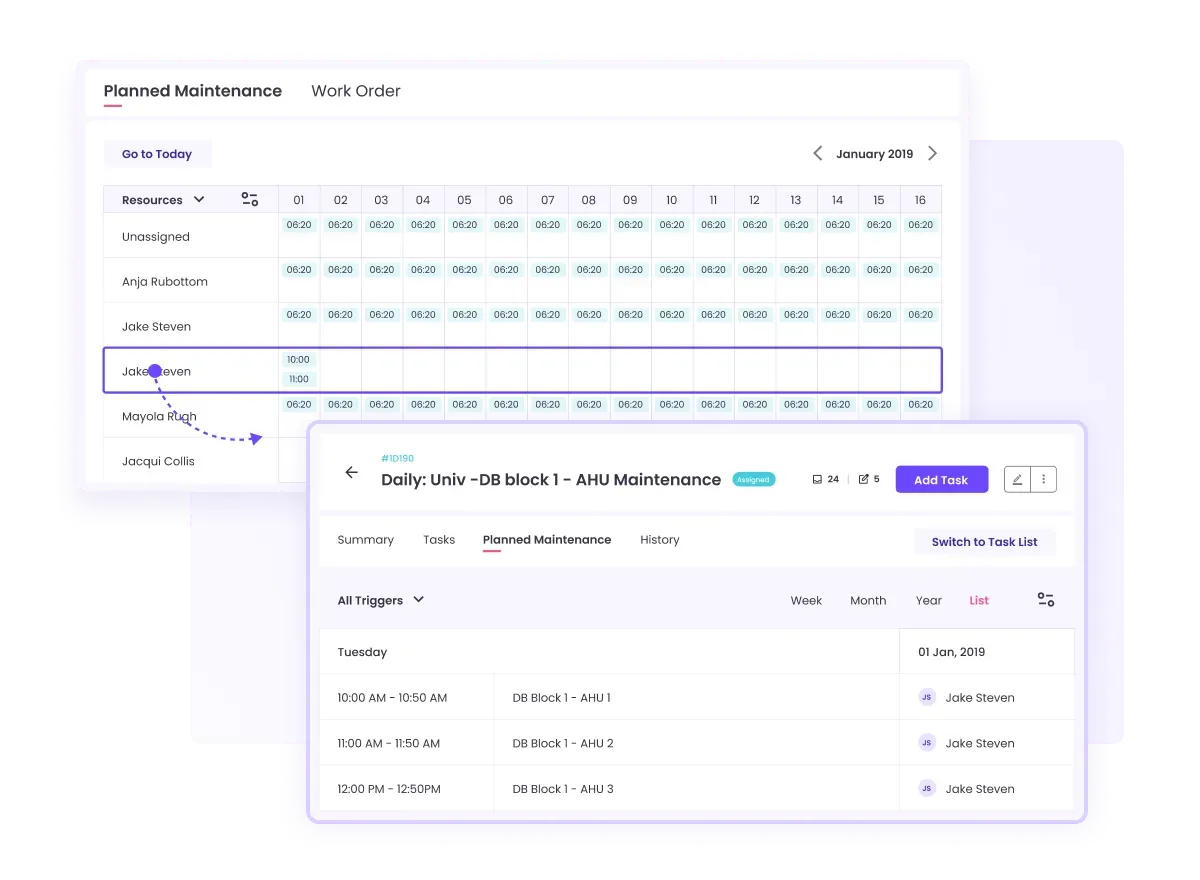

Job & resource planner

This CMMS feature takes the guesswork out of scheduling and resource allocation by providing a comprehensive overview of all upcoming maintenance activities. It allows you to plan and allocate resources with ease, helping you balance workloads, avoid scheduling conflicts, and ensure that all tasks are covered.

For example, the PPM schedule for the school's HVAC system displays the maintenance due dates for each asset, all relevant tasks, and all needed resources.

You can see which technicians are available, their skill levels, and any other ongoing tasks they are assigned to. It can also help in tracking the availability of necessary parts and tools, ensuring that everything needed for the job is on hand.

The system can also auto-populate the PPM details for HVAC with a list of eligible assets and provide a list of qualified vendors and technicians.

This level of detailed planning helps avoid last-minute scrambles for resources and ensures that maintenance activities proceed smoothly.

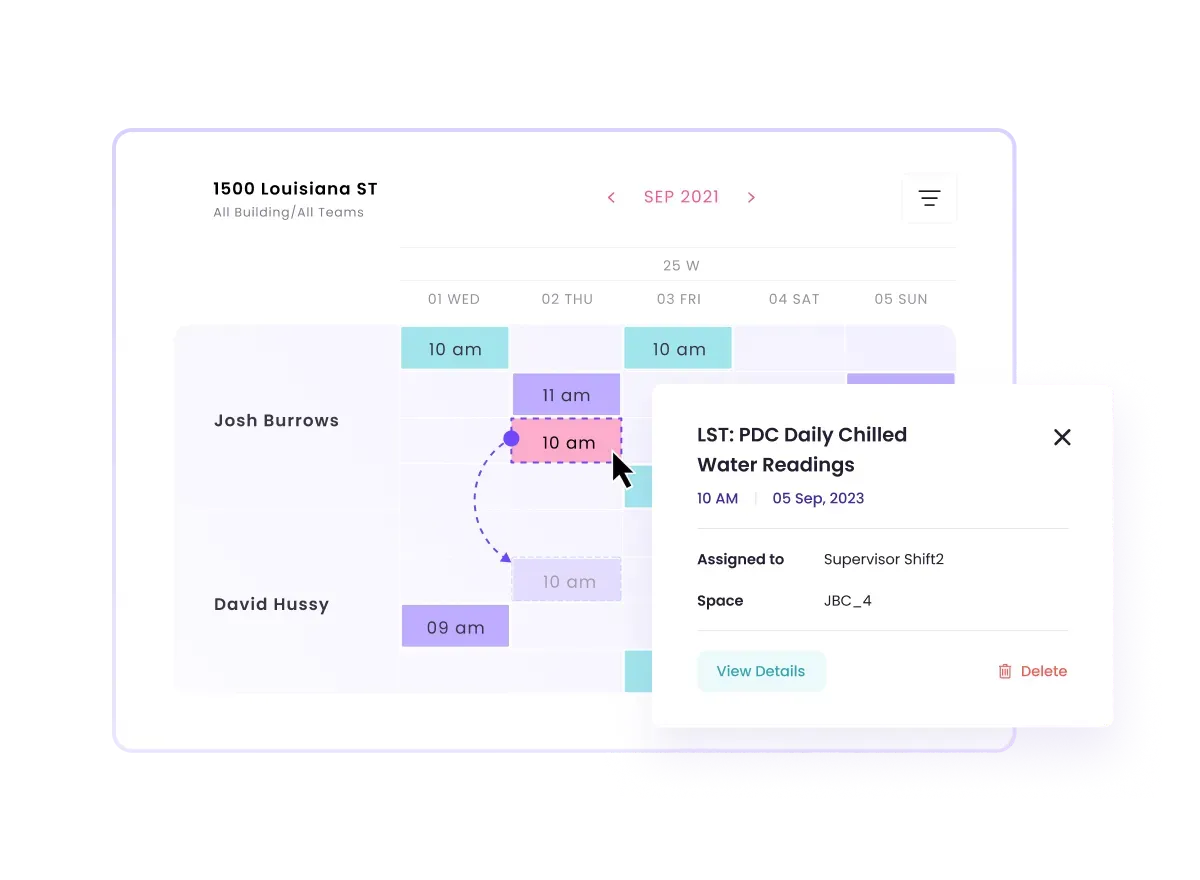

Condition-based triggers

This is one of the most important features to look for in a CMMS. A CMMS with this capability can automatically trigger maintenance based on the condition of your assets.

For example, a specific sensor in an HVAC unit detects that the temperature is rising beyond acceptable levels, indicating a potential malfunction. Instead of waiting for the HVAC to fail and disrupt classes, the CMMS automatically generates a priority work order.

Technicians are alerted to investigate and fix the issue before it impacts the comfort of students and staff. This proactive approach helps prevent small issues from escalating into major disruptions.

Essential CMMS features to run your PPM on autopilot

While the above essential features streamline your workflow and reduce manual efforts, a connected CMMS can take you much further. Here are some features that optimize your PPM engine, enhancing the efficiency of your maintenance program so your team to focus on it without worrying about repetitive and time-consuming manual tasks.

Intelligent job assignment

Imagine not having to manually assign tasks to your technicians. With an intelligent assignment feature, the CMMS does it for you. By analyzing the skills, availability, and location of your technicians, the system automatically assigns the right person for the job. This smart allocation saves you time and ensures tasks are handled by the most qualified personnel.

During a busy schedule where technicians are scarce, your CMMS can automatically assign tasks to the most qualified and available technician. For instance, it might assign an HVAC technician who is already working on the science building to a minor air-conditioning repair on the same floor, streamlining the process and saving time.

Fully mobile inspections

A mobile app interface allows technicians to access their task assignments, view checklists, record findings, and document repairs directly from their mobile devices. The app can also mandate technicians to capture photos or videos of equipment or repairs, providing a visual record of their work.

Consider a technician inspecting the school's security system. Using the mobile app, they can access the inspection checklist, note issues like malfunctioning cameras or broken alarm sensors, and capture photos of the specific problems. This information is then automatically uploaded to the CMMS, creating a comprehensive and detailed record of the inspection.

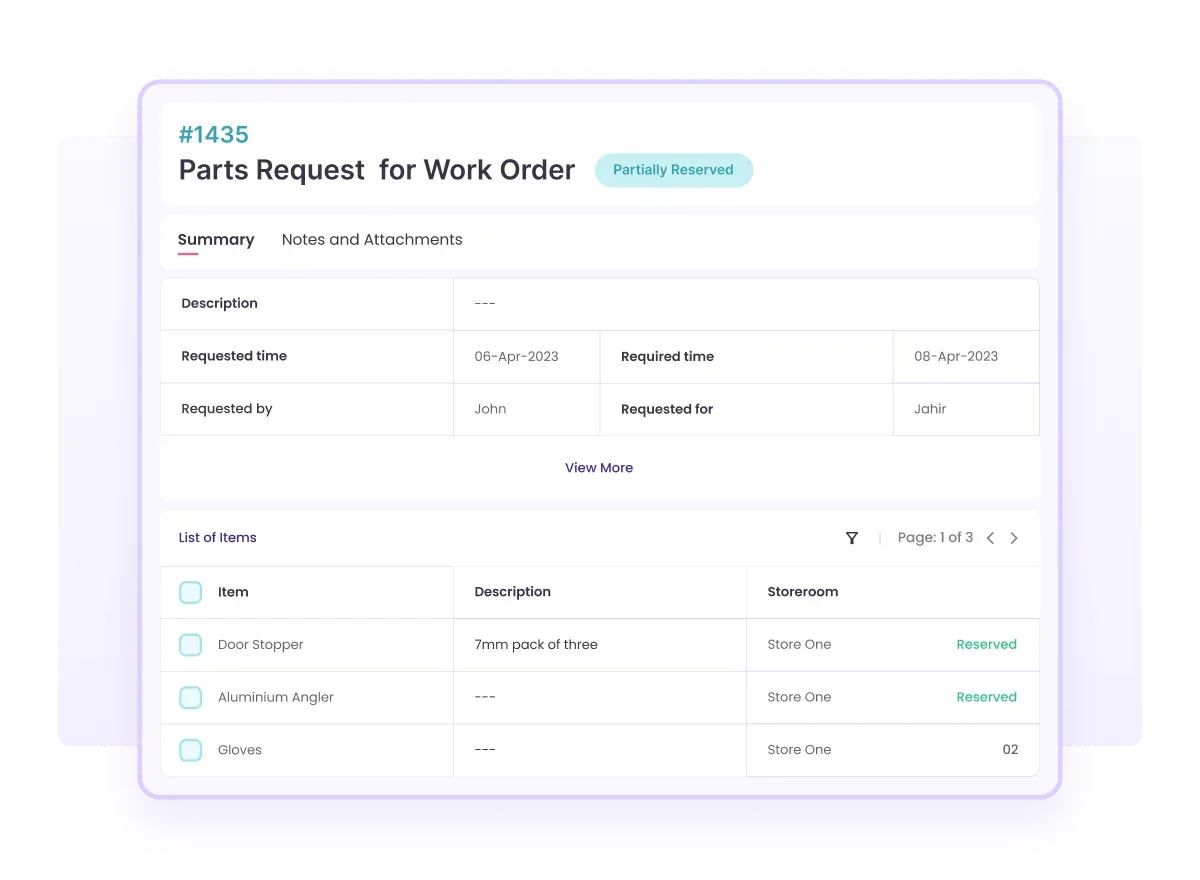

Integrated inventory tracking

Look for a CMMS that integrates effortlessly with your inventory system and PPM engine, allowing you to request items from stock as required for work orders, track their storage locations, and automate reorder points when supplies run low.

When a technician discovers a burnt-out bulb or faulty ballast when inspecting the classroom lighting, they can use the mobile app to request a replacement part. The CMMS immediately checks the inventory, identifies that the part is in stock, and provides the exact storeroom details. This process saves time and effort, enabling the technician to complete the repair quickly and efficiently.

Suggested read: Streamlining Inventory Management with CMMS

PPM for safe and efficient campus operations

Educational institutions need a proactive approach to maintenance now more than ever. Connected CMMS enables that and much more by seamlessly connecting people, processes, and systems across your campus, creating a unified platform for managing PPM tasks.

Think of it this way: just as you wouldn't operate your campus without reliable internet or modern classrooms, a connected CMMS is no longer optional. A preventive maintenance program driven by connected CMMS promises a safe and efficient campus that practically runs itself, requiring minimal human intervention. Take a leap and explore the benefits for yourself today.

More from Facilio