Managing Work Permit

A work permit is a formal document that grants authorization to perform specific work or tasks within a facility or property. Work permits are essential for ensuring safety, compliance, and effective management of maintenance activities. They play a crucial role in maintenance management by ensuring that work orders are executed safely, efficiently, and in compliance with regulations. They provide a structured framework for managing work activities and mitigating risks associated with maintenance tasks within facilities. The integration of work permits with work orders helps streamline operations, enhance safety practices, and optimize resource allocation.

Significance of Work Permits

Here's how work permits are typically used for serving work orders in the facilities management industry:

- Safety Compliance - Work permits are often required for tasks that involve potential safety hazards, such as electrical work, hot work (welding, cutting), confined space entry, or working at heights. Before starting such tasks, workers must obtain the appropriate work permit to ensure that safety measures are in place and risks are mitigated.

- Authorization Process - Work permits establish an authorization process where work orders are reviewed and approved by designated personnel (such as facility managers, safety officers, or supervisors) before work can commence. This process ensures that the necessary resources, tools, and precautions are in place.

- Scope Definition - Work permits clearly define the scope of work to be performed. This includes specifying the location, description of work, tasks involved, tools/equipment required, and any special instructions or precautions.

- Risk Assessment - Work permits often involve a risk assessment process where potential risks associated with the work are identified, evaluated, and controlled. This helps in implementing appropriate safety measures and ensuring worker competence.

- Coordination and Planning - Work permits facilitate coordination and planning of maintenance activities. By linking work permits to work orders, facilities management teams can prioritize tasks, allocate resources effectively, and minimize disruptions to operations.

- Compliance Monitoring - Work permits ensure compliance with regulatory requirements and industry standards. They help demonstrate that necessary precautions and procedures are followed to protect workers, the environment, and the facility.

- Record Keeping - Work permits serve as official documentation of authorized work activities. They provide a record of who performed the work, when it was done, and under what conditions.

- Emergency Response Preparedness - Work permits often include emergency response procedures in case of unforeseen incidents or hazards during the work. This ensures that workers are prepared to respond effectively to emergencies.

Types of Work Permit

There are several types of work permits that may be issued depending on the nature of the work being performed and the associated risks. The specific types of work permits can vary between organizations and industries, but here are some common types:

- Hot Work Permit - This type of permit is required for tasks involving open flames, sparks, or high temperatures, such as welding, cutting, soldering, or grinding. A hot work permit ensures that fire prevention measures are in place to prevent fire hazards.

- Confined Space Entry Permit - For work involving confined spaces (e.g., tanks, vessels, vaults), a confined space entry permit is necessary to assess and control risks associated with confined space entry, including air quality monitoring, ventilation, and rescue procedures.

- Electrical Work Permit - This permit is required for electrical maintenance or installation tasks to ensure compliance with electrical safety standards and procedures, including lockout/tagout (LOTO) procedures.

- Work at Height Permit - For tasks involving work at elevated heights (e.g., roofs, scaffolding, elevated platforms), a work at height permit is necessary to assess fall hazards, provide fall protection measures, and ensure worker safety.

- Excavation Permit - When performing excavation or trenching activities, an excavation permit is required to assess ground stability, underground utilities, and implement appropriate safety measures to prevent cave-ins or accidents.

- Permit to Work in Hazardous Areas - For tasks in areas where hazardous substances (e.g., chemicals, gasses) are present, a permit to work in hazardous areas may be required to mitigate risks associated with exposure to hazardous materials.

- Isolation Permit - When isolating or shutting down equipment or systems (e.g., machinery, pipelines) for maintenance or repair, an isolation permit is used to ensure proper isolation procedures are followed to prevent accidental start-up or release of energy.

- Cold Work Permit - This permit may be required for tasks performed in cold environments where specific precautions are needed to protect workers from cold-related hazards such as frostbite or hypothermia.

- General Work Permit - In some cases, a general work permit may be issued for routine or low-risk maintenance tasks that do not fall under specific permit categories but still require formal authorization and compliance with safety procedures.

These are examples of common work permits used in facilities management and maintenance operations. The issuance of work permits helps ensure that work is conducted safely, risks are identified and controlled, and appropriate precautions are taken to protect workers, property, and the environment. Organizations should tailor their work permit system to address specific risks and regulatory requirements applicable to their industry and operational context.

Granting Work Permit

The responsibility for granting work permits typically lies with the facility management team or designated personnel within the organization. The issuance of work permits involves a formal authorization process to ensure that work is conducted safely and in compliance with relevant regulations and standards.

The specific individuals or departments involved in granting work permits may vary depending on the organization and the nature of the work being performed. However, here are common roles of stakeholders involved in the work permit issuance process:

- Facility Manager - The facility manager or facility management team oversees the overall maintenance and operations of the facility. They are responsible for authorizing work permits and ensuring that maintenance activities align with organizational objectives and safety protocols.

- Safety Officer - A designated safety officer or safety team plays a critical role in reviewing and approving work permits, especially for tasks involving potential safety hazards. The safety officer ensures that appropriate risk assessments are conducted and that safety measures are in place before work begins.

- Maintenance Supervisor - The maintenance supervisor or team leader directly responsible for overseeing maintenance tasks may be involved in the work permit process. They ensure that work permits align with work orders, prioritize tasks, and allocate resources accordingly.

- Engineering or Technical Team - For specialized maintenance tasks requiring technical expertise (e.g., electrical, HVAC, plumbing), engineers or technical experts may be consulted during the work permit issuance process to assess the feasibility and safety of proposed work.

- Regulatory Authorities - In certain industries or for specific types of work (e.g., hazardous material handling, confined space entry), regulatory authorities may need to be consulted or involved in granting work permits to ensure compliance with legal requirements.

The process of granting work permits typically involves the following steps:

- Work Order Submission - The maintenance team submits a work order specifying the nature of the work to be performed.

- Risk Assessment - The safety officer or designated personnel conduct a risk assessment to identify potential hazards associated with the work.

- Authorization Review - The facility manager or authorized personnel review the work order and associated risk assessment to determine if a work permit is required and if additional precautions are needed.

- Work Permit Issuance - Once approved, a formal work permit is issued detailing the scope of work, safety precautions, authorization conditions, and any other relevant information.

- Work Execution - The authorized personnel can then proceed with the approved work activities under the conditions specified in the work permit.

By involving multiple stakeholders and following a structured authorization process, organizations can ensure that maintenance activities are carried out safely, efficiently, and in compliance with regulatory requirements. Work permits serve as a critical tool for managing risk and maintaining operational integrity within facilities management operations.

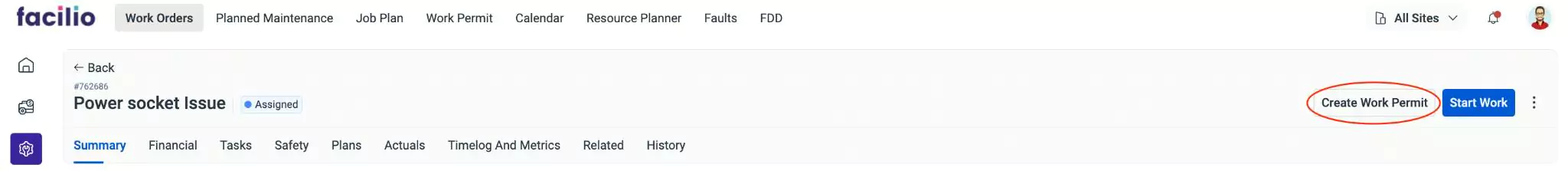

Creating a Work Permit

The application facilitates the creation of work permits in conjunction with work orders, utilizing predefined checklists for pre and post-work completion checkpoints. This functionality ensures that maintenance personnel systematically adhere to safety measures and complete essential tasks before and after fulfilling their assignments.

To create a work permit,

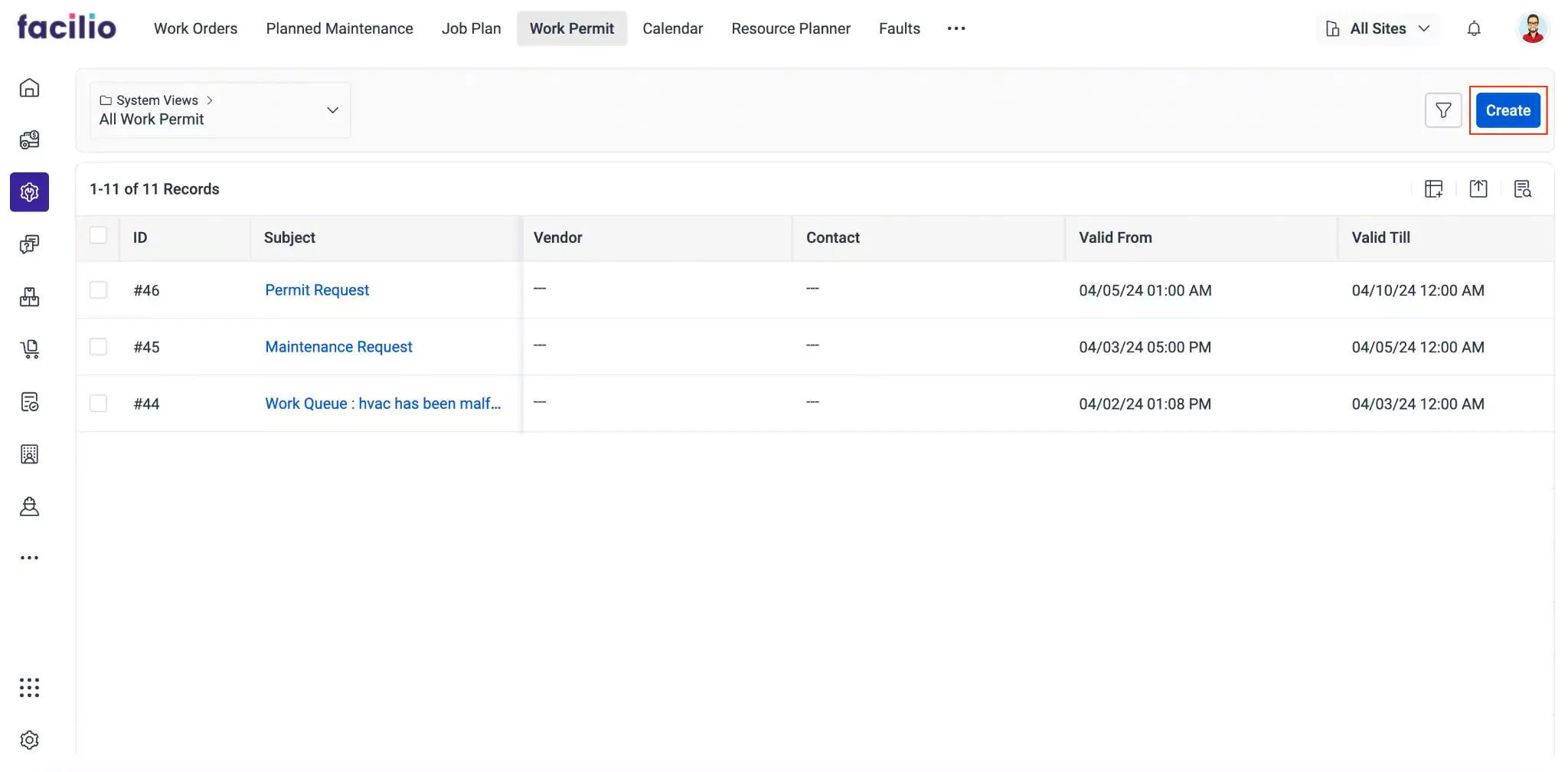

Navigate to the Work Permit section. The list of work permits created appears, shown below.

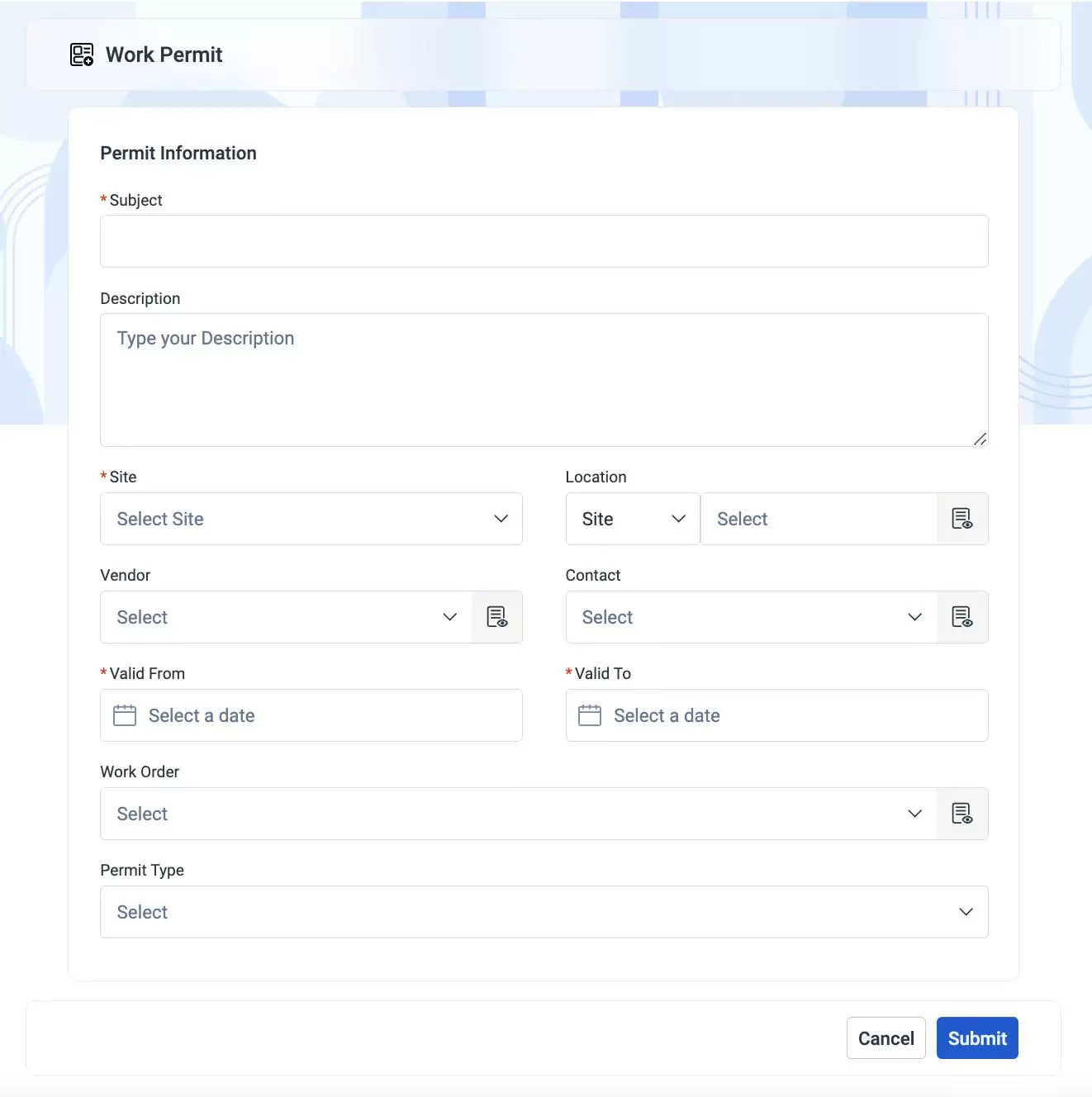

Click Create at the top right. The Work Permit - Permit Information screen appears.

Update the required fields in this screen.

- Subject - Brief title summarizing the work permit.

- Description - A short note explaining the purpose of the work permit.

- Site - Specific area where the work will be conducted.

- Location - Physical address or coordinates of the work site.

- Vendor - Name of the vendor company or contractor responsible for the work.

- Contact - Name of the person for whom the permit is issued

- Valid From - Start date of the work permit's validity period.

- Valid To - End date of the work permit's validity period.

- Work Order - The work order in association with which the work permit is being created.

- Permit Type - Classification of the work permit based on the nature of the associated work order. Read the Types of Work Permit section for more information.

Click Submit. The work permit is now successfully associated with the work order.

Executing Work Orders Integrated with Work Permit

Executing work orders integrated with work permits ensures comprehensive safety compliance and procedural adherence throughout task execution. By associating a checklist, critical safety measures are enforced before work order commencement. Work permit prerequisites must be completed and approved before initiating the work order, ensuring regulatory compliance. Upon approval, the work order begins, and post-completion checklists are addressed as necessary. Final approval is obtained before closing the work order, guaranteeing all safety protocols are met. The upcoming sections explain the work permit related activities to be completed during the course of work order execution.

Step 1: Completing Prerequisites Checklist

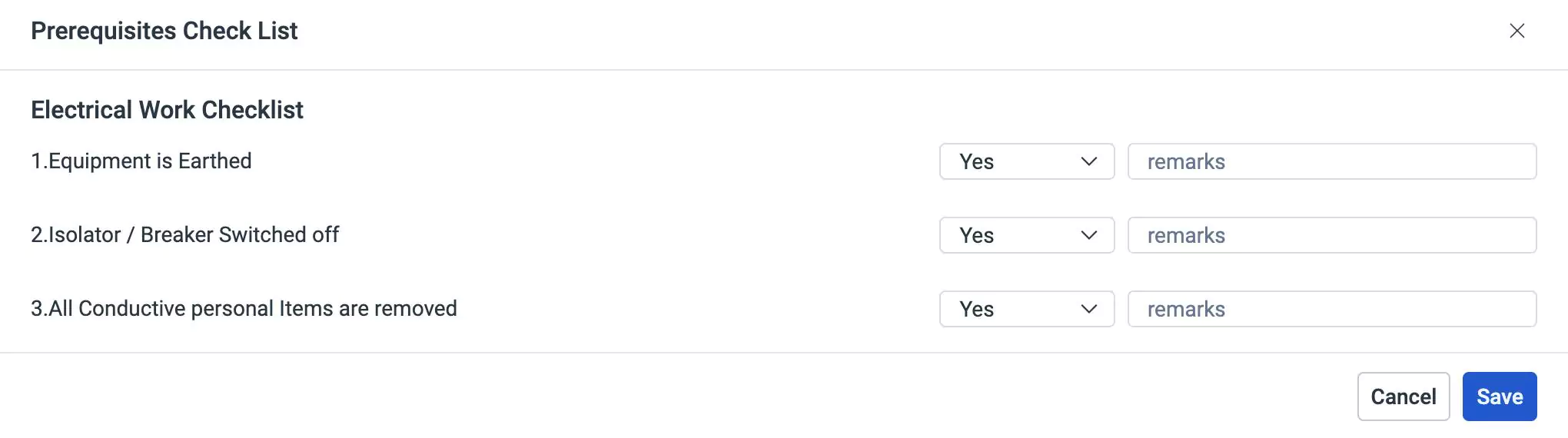

When a work permit is associated with a work order, it's essential that the professional fulfills the prerequisites outlined within the permit before proceeding with work. For instance, if the work permit requires wearing safety boots and turning off the main breaker before initiating electrical repairs, the professional must ensure compliance with these basic safety measures. This ensures a safe working environment and minimizes the risk of accidents or injuries while performing specific tasks. To complete the prerequisites,

Click Submit Prerequisites at the top right of the work order Summary screen.

The prerequisites checklist appears as shown below.

Update the status of the line items in the checklist, enter the remarks (if any), and click SAVE. The updates are now successfully saved.

An approval is triggered to the approver to validate the checklist compliance.

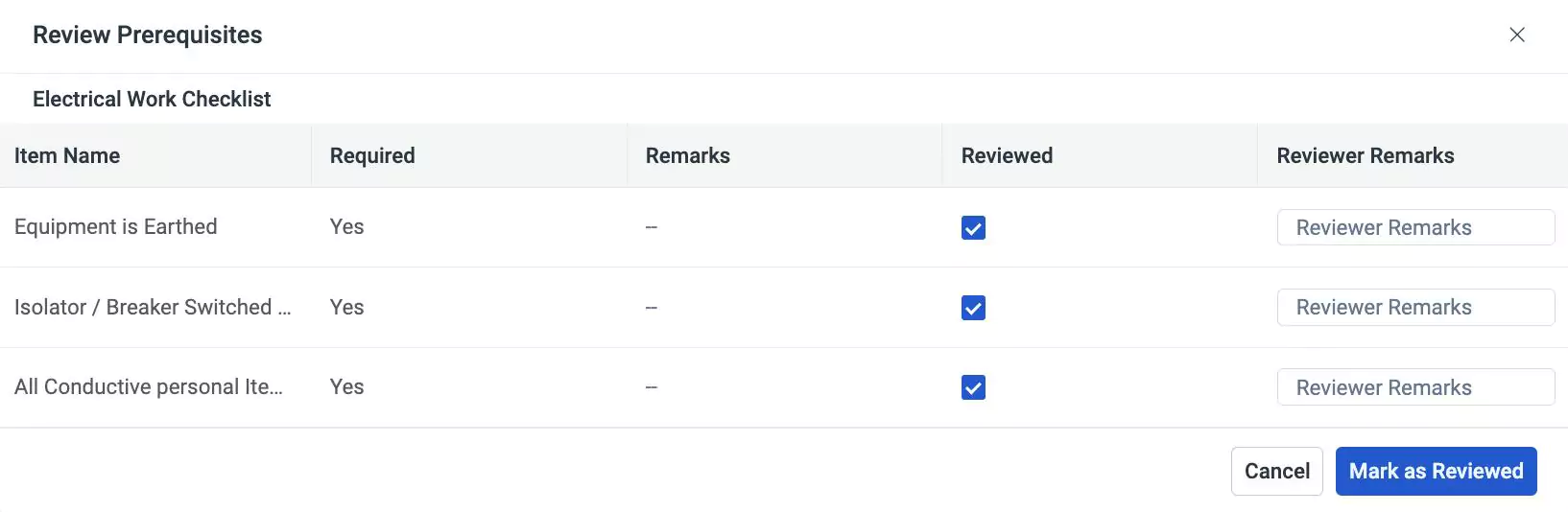

Step 2: Approving Prerequisites Checklist

The assigned supervisor or safety officer must approve the prerequisites marked as completed by the professional, to ensure compliance and allow the professional to execute the task. Before work begins, the approving personnel verify that all prerequisites are met by clicking Review Prerequisite to ensure a safe working environment.

The approver can confirm adherence to prerequisites by marking the line items as reviewed and clicking Mark as Reviewed. They can also add review comments (if any) against each line item before approval.

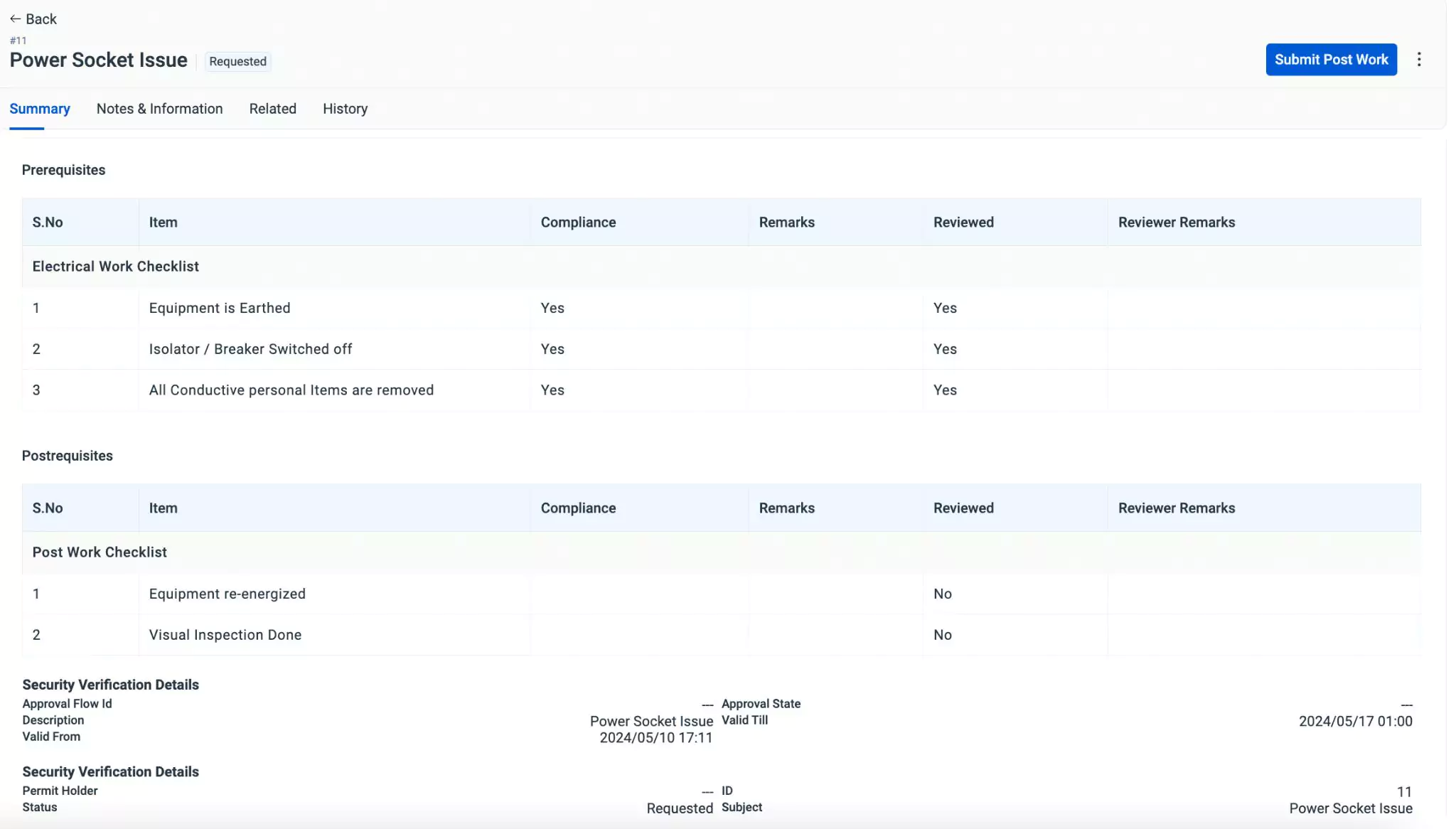

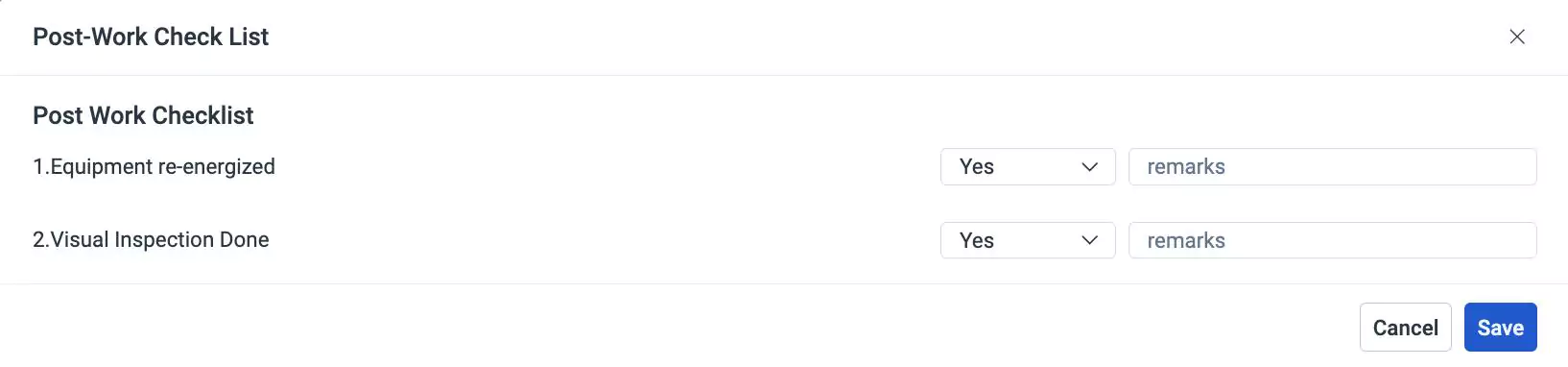

Step 3: Completing Post Work Checklist

Once the main tasks outlined in the work order are completed, it's crucial to address the post-work checklist associated with the work permit. This checklist ensures that all necessary steps are taken to safely conclude the job and restore the work area to its proper condition. For example, if the work involved electrical repairs, the post-work checklist might include steps such as verifying that all electrical connections are secure, turning the main breaker back on, and ensuring that the work area is free of any hazards. By following these post-work procedures, the professional ensures the worksite is safe and ready for regular use, preventing any potential issues from arising after the work has been completed. To complete the post work checklist,

Click Submit Postwork at the top right of the work order Summary screen.

The post requisites checklist appears as shown below.

Update the status of the line items in the checklist, enter the remarks (if any), and click SAVE. The updates are now successfully saved.

Again, an approval is triggered to the approver to validate the checklist compliance.

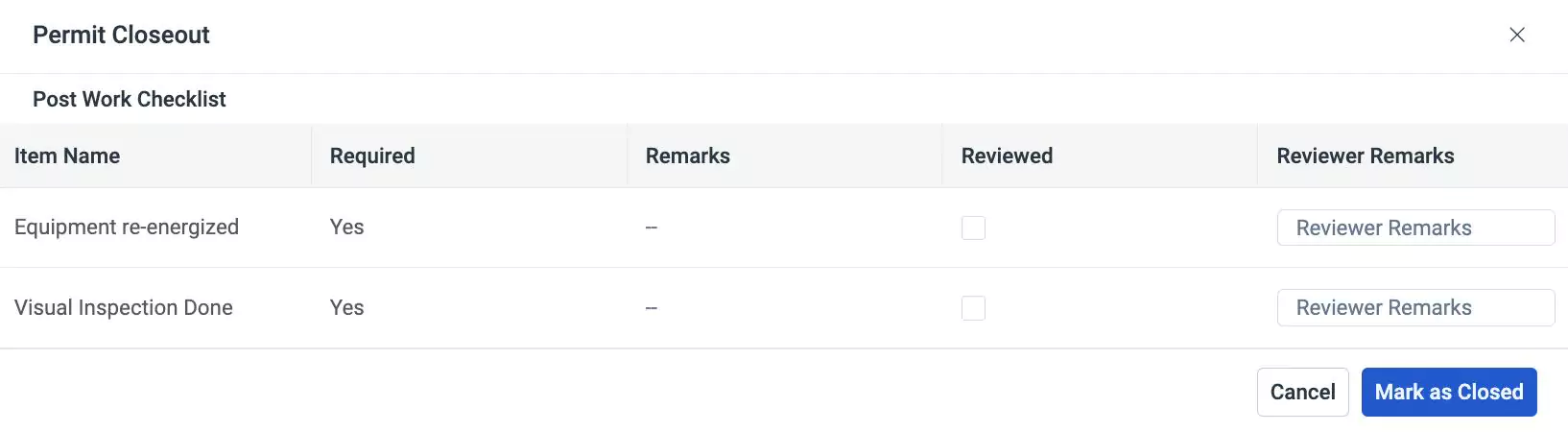

Step 4: Approving Post Work Checklist

The assigned supervisor or safety officer must approve the post work checklist marked as completed by the professional, to ensure compliance and allow the professional to close the task. After the work is completed, the approving personnel must again review and approve the post-completion checklist by clicking Review Post Work to confirm that all tasks have been safely and correctly executed, and that the work area is properly restored.

If the Is Work Permit Needed field was set to Yes during the creation of a work order, the administrator must have created a work permit in association with the work order for the professional to commence work, as per application requirements.

The professional can use the vendor portal to access and submit the pre and post work checklist. Also, the approver can use the vendor portal to review and grant work permits.

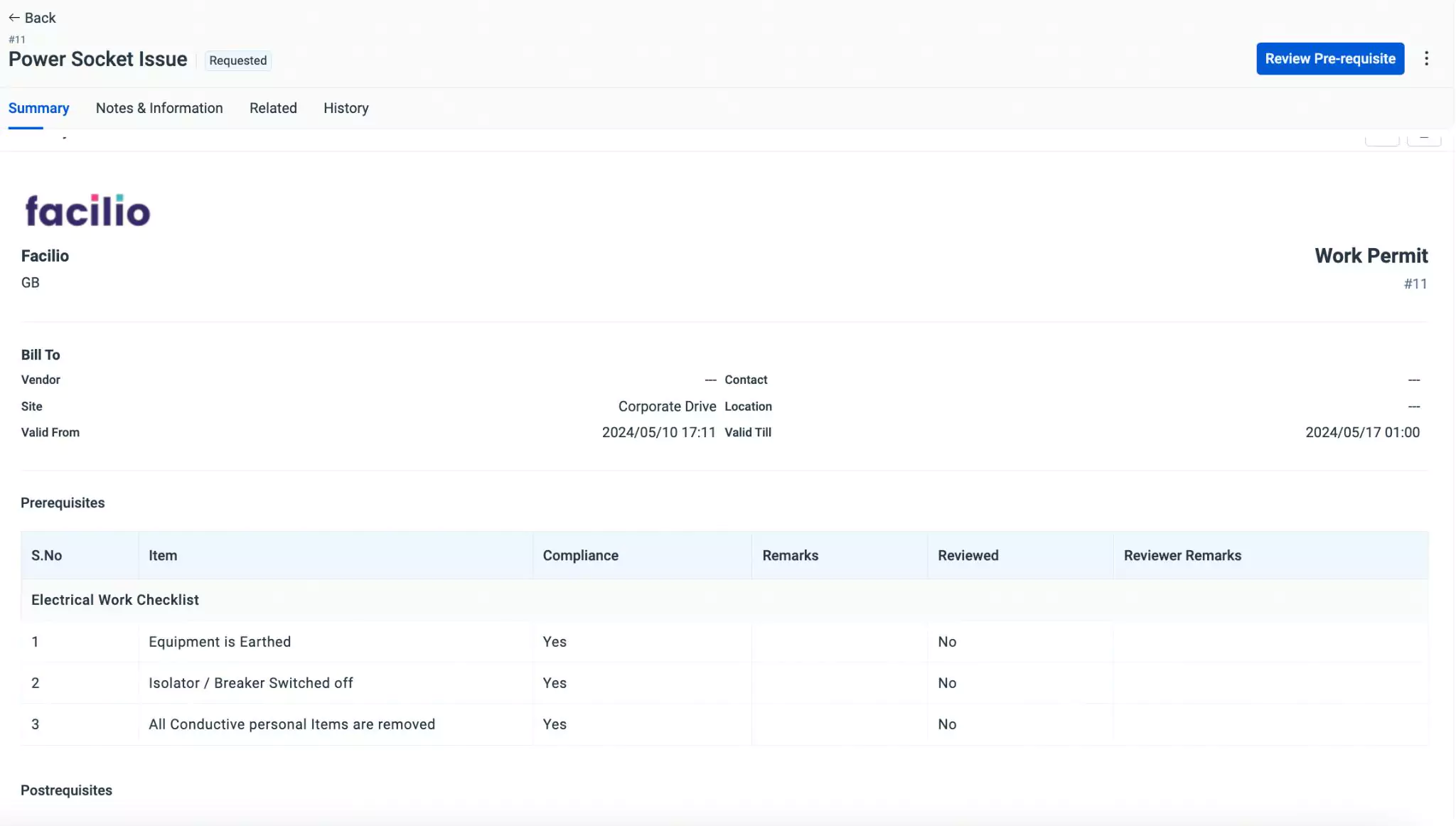

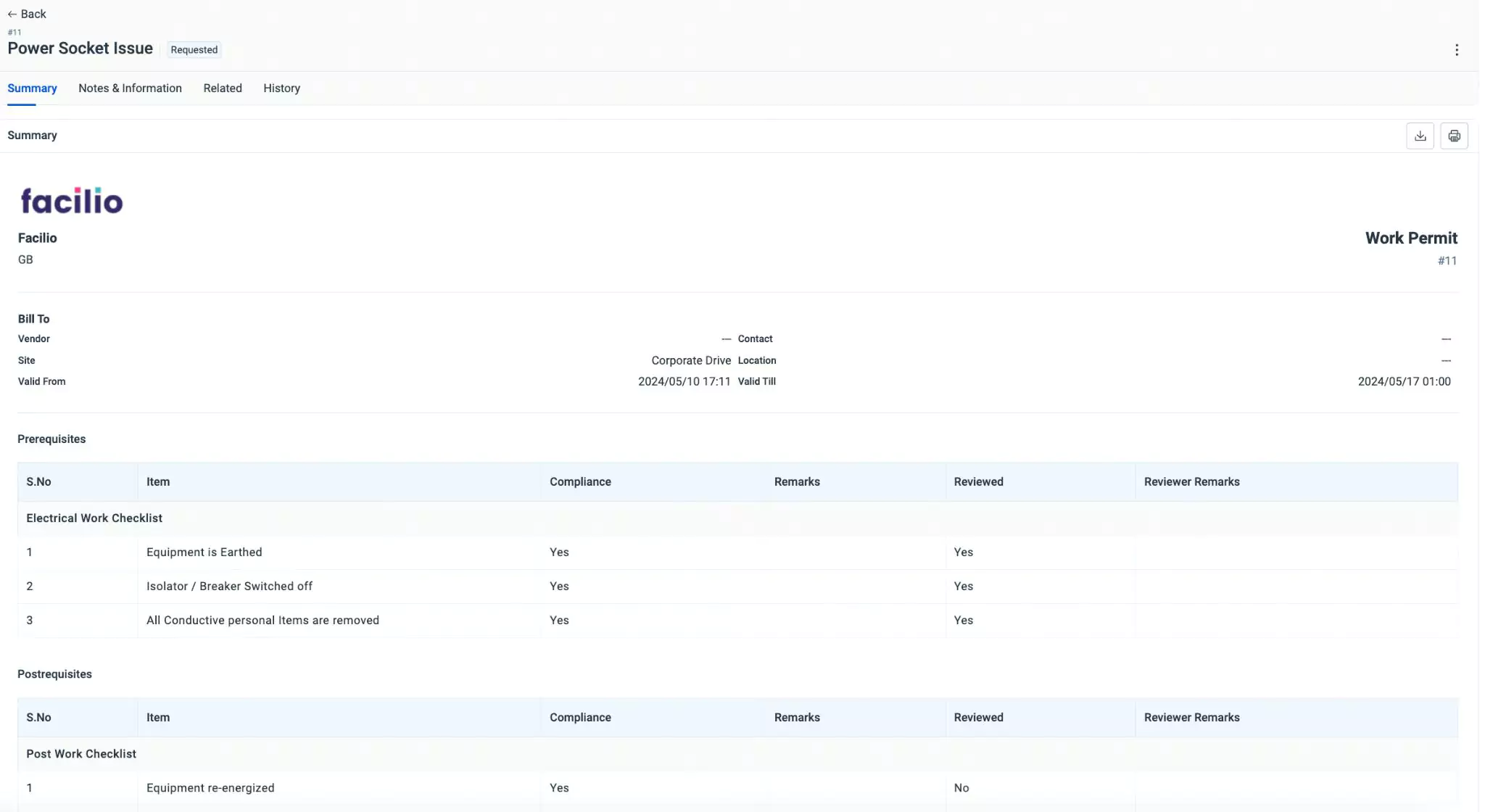

Viewing Work Permit Information

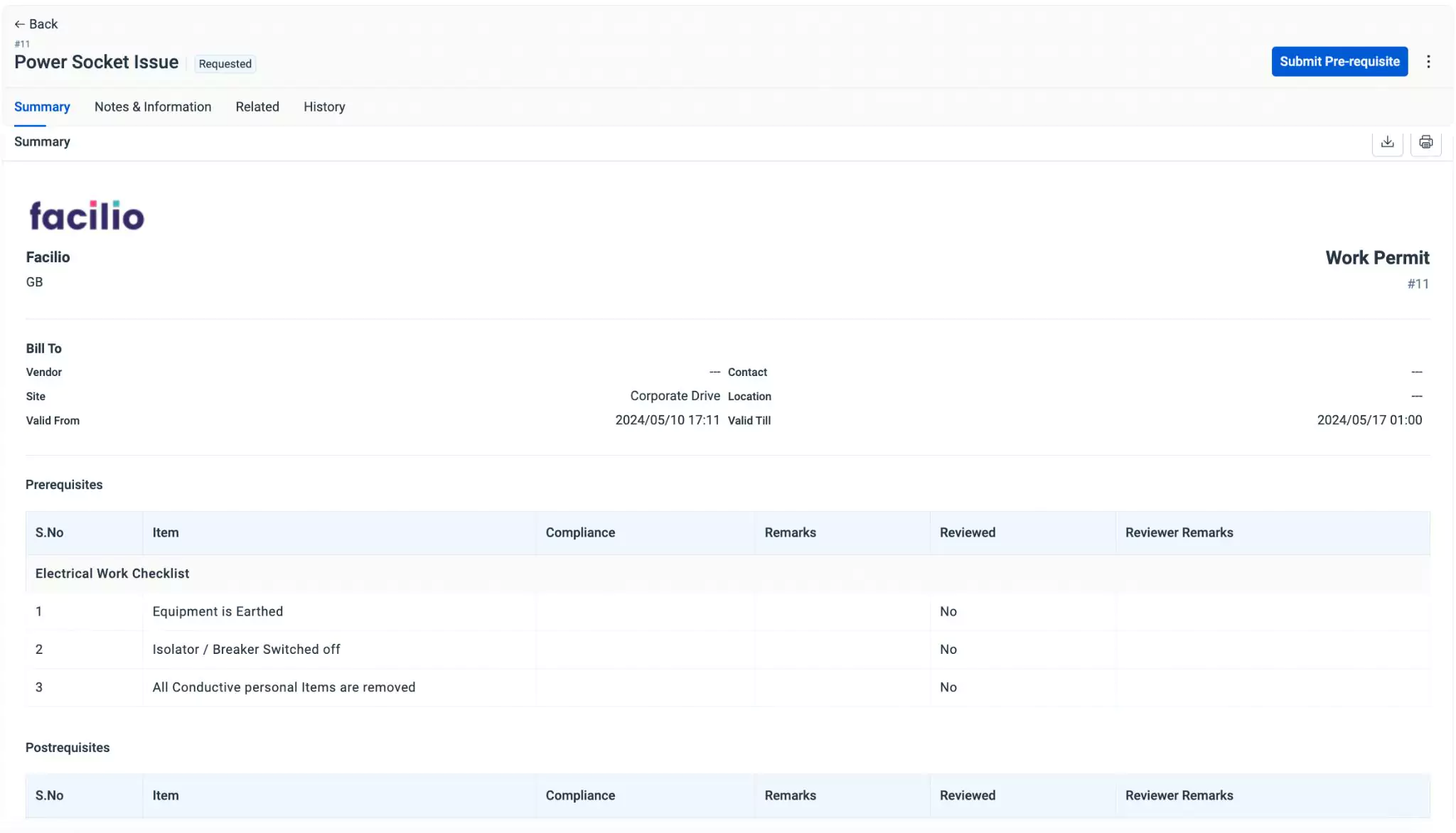

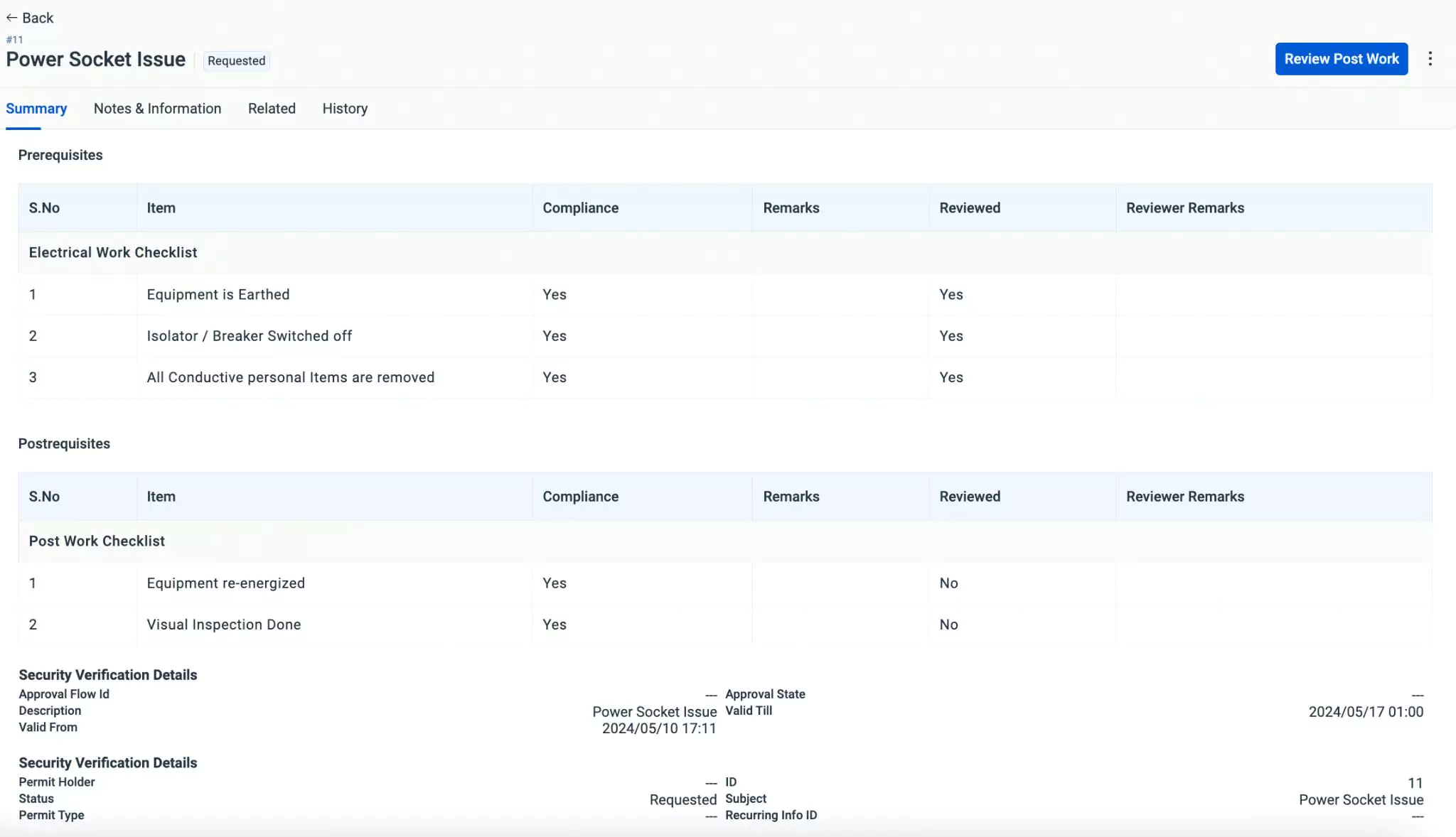

You can view the details of a work permit by clicking the record from the list of work permits. Upon clicking the record, the corresponding Summary screen appears by default as shown below.

Summary

The Summary section displays the basic details of the work permit, including the associated work order, the vendor, creation time, validity information, and more. It also shows the prerequisites and the post-work checklist configured for the work order.

Notes and Information

The Notes and Information section provides additional details about the work permit. It allows you to add notes and attach documents regarding the work permit, if any.

Related

The Related section provides a convenient overview of any related entities or documents associated with the current work permit. It includes links to documents, or other relevant information, allowing users to easily navigate between related items for context or further action.

History

The History section maintains the log of all activities that take place with respect to the work permit, for future reference. The recorded information helps you understand the course of action or changes the record has undergone. The displayed details include the action taken place, the user who performed the action and the date and time of occurrence.

Exporting the Work Permit

The application enables users to save the work permit in a digital format, such as PDF, facilitating easy sharing, archiving, or printing of the details. This feature ensures accessibility and convenience for users who may need to reference or distribute the work permit across different platforms or for documentation purposes. You can navigate to the work permit Summary section use the following icons to export the work permit information:

| Icon | Action/Description |

|---|---|

| To save the work permit document in PDF format for offline access or sharing | |

| Print a hard copy of the work permit document for documentation or reference purposes |