Handling Maintenance

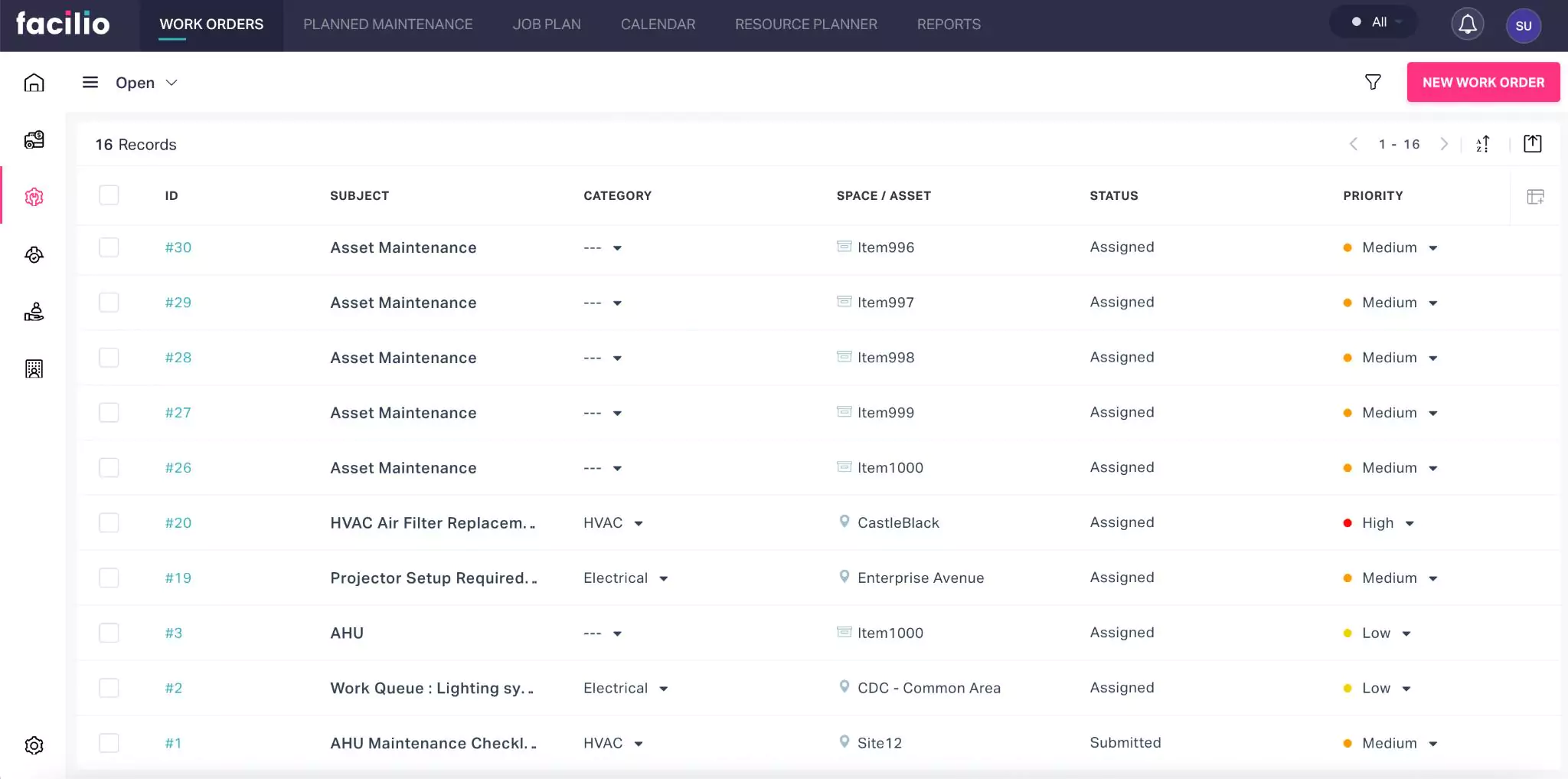

The maintenance module of the application streamlines the strategies used to efficiently plan, schedule, and execute work orders. This ensures the resolution of critical maintenance issues, minimizes asset downtime, maintains equipment in optimal condition, and upkeeps the facility. It includes managing both planned and unplanned work orders. To navigate to this module, click the  (Maintenance) icon in the sidebar menu. The WORK ORDERS section appears by default as shown below.

(Maintenance) icon in the sidebar menu. The WORK ORDERS section appears by default as shown below.

The upcoming section explains how to create a work order, process a work order request, execute a work order, and view the details of it.

Managing Work Orders

Unplanned maintenance is carried out to restore an asset to a condition, in which it can perform its intended function and stabilize other abnormalities in a facility.Configuring Planned maintenance

The prime objective of scheduling planned maintenance work is to reduce the efforts on corrective (reactive) work. Scheduling work also provides a steady,Configuring Job plan

A job plan is a detailed set of instructions outlining the tasks, and resources necessary to complete a specific maintenance activity. Job plans are crucial for maintainingsManaging Work Permit

A work permit is a formal document that grants authorization to perform specific work or tasks within a facility or property. Work permits are essential forAccessing Calendar

Calendar offers a visual representation or overview of scheduled tasks. In other words, the calendar provides a date-centric view,Accessing Resource Planner

The resource planner helps understand staff availability and occupancy. It allocates and manages the resources needed to complete work orders efficiently within the stipulated.