Physical assets are at the core of industries like manufacturing, healthcare, utilities, retail, self-storage, and office space. Without maintaining their longevity and performance, these industries would not be able to function.

The bad news? Maintenance management is hard work.

The good news? Predictive maintenance software reduces breakdowns by 70%, increases productivity by 25%, and reduces maintenance costs by 25%.

In this post, we discuss how predictive maintenance works and your choices for the best predictive maintenance software in 2024.

What is Predictive Maintenance Software?

Predictive maintenance software combines equipment monitoring tools with data analytics to analyze equipment performance and predict potential failures. It uses real-time monitoring tools such as IoT sensors and gauges to track equipment temperature, vibrations, and sound to flag potential problems.

The collected information syncs with the software, which runs predictive maintenance analytics to assess equipment performance and determine if any repairs are required. The analysis also helps you proactively develop a maintenance strategy and cut down on unplanned downtime.

Predictive maintenance software is the face of Industry 4.0—a new stage in the manufacturing industry with intelligent solutions and automation.

Benefits of Predictive Maintenance

The premise of predictive maintenance is constant monitoring. Here are four benefits you get from a predictive maintenance solution:

- Fewer equipment failures: Employing condition monitoring techniques to inform maintenance strategies provides your operations and maintenance teams with real-time data on asset health. Asset health data lets you take preventative measures before a failure occurs, thereby significantly reducing equipment breakdowns. Additionally, it contributes to an extended asset lifespan, resulting in a reduction in operating expenditures. Research indicates that predictive analytics delivers a remarkable tenfold return on investment and savings ranging from 30% to 40%.

- Reduced mean time to repair: Condition monitoring tools alert technicians when they detect a problem, reducing the mean time required (MTTR) to repair equipment by almost 60% and limiting the scope of any potential damage.

- Reduced operations cost: When you can forecast when machines need maintenance, you can plan to do it at the right times instead of guessing. This helps you cut down on how often maintenance is needed, spend less on parts, and keep fewer spare parts in stock.

- Increased workplace safety: Machine-related workplace accidents are dangerous and can lead to lawsuits, levying significant financial impact on your organization. Early detection of maintenance issues reduces the risk of catastrophic equipment failures and keeps your workforce safe.

How does Predictive Maintenance Work?

Predictive maintenance uses monitoring techniques such as thermography, vibration analysis, ultrasound, oil analysis, and electrical current signature analysis to detect faults in a machine. Predictive maintenance programs are dependent on the Internet of Things (IoT) and condition-based monitoring equipment. Together, these technologies allow sensors placed on equipment to connect and exchange data in real-time.

Related Read: Equipment Maintenance Software

You can think of this process as machines “talking” to the software. In this conversation, the machine helps the software recognize trends and set parameters for performance. When a sensor detects spikes or dips outside of these parameters, it alerts the maintenance team that the equipment is nearing failure.

Here is a step-by-step breakdown of the process:

- Predictive maintenance software gathers real-time data from sensors, equipment logs, and building or machinery control panels

- It applies machine learning algorithms to analyze historical data and identify patterns

- It detects deviations from normal equipment behavior

- It forecasts potential equipment failures based on identified patterns

- It generates optimized maintenance schedules to address issues proactively

Related Read: Best Building Management Software

Key Features of Predictive Maintenance Software

Here are five key features you should look for in a predictive maintenance solution:

1. Asset Management

The asset management process refers to the tracking, maintaining, and optimization of your company’s assets, such as facilities, machinery, equipment, and fleet.

Asset data helps you ensure timely maintenance, prevent breakdowns, and maximize facility uptime by tracking down every asset within your organization. Learn More on Best Fixed Asset Management Software

2. Preventative Management

Preventative maintenance is the process of scheduling and planning maintenance tasks to identify and rectify issues that impact equipment performance.

By identifying such issues early on, you resolve them before they lead to breakdowns. You also reduce capital and operating expenditures by cutting down on reactive maintenance costs.

Related Read: Understanding the Benefits of Preventive Maintenance

3. Reporting and Analytics

Reporting and analytics is the collection and analysis of data related to maintenance, operations, and asset performance. It allows you to visualize data, derive actionable insights to improve processes, and get a 360-degree view of all data and activities associated with your facilities.

4. Work Order Management

Predictive maintenance software automates the creation, assignment, and tracking of work orders based on the insights provided by equipment sensors.

With this feature in your toolkit, you don’t need manual data entry. Plus, your date remains accurate and up-to-date via real-time updates and closure of work orders, all of which are essential for effective maintenance planning and execution. Learn more on Best Work Order Software

5. Alert Configurability

Customizable alert settings in predictive maintenance software allow you to create and adjust alerts and notifications according to particular conditions and thresholds. They’re important for establishing a proactive maintenance strategy and ensuring that the right people are informed at the right time about any maintenance issues.

The Best Predictive Maintenance Software in 2024

Here’s our hand-picked list of the six best predictive maintenance software of 2024, detailing their key features as well as pros and cons:

1. Facilio

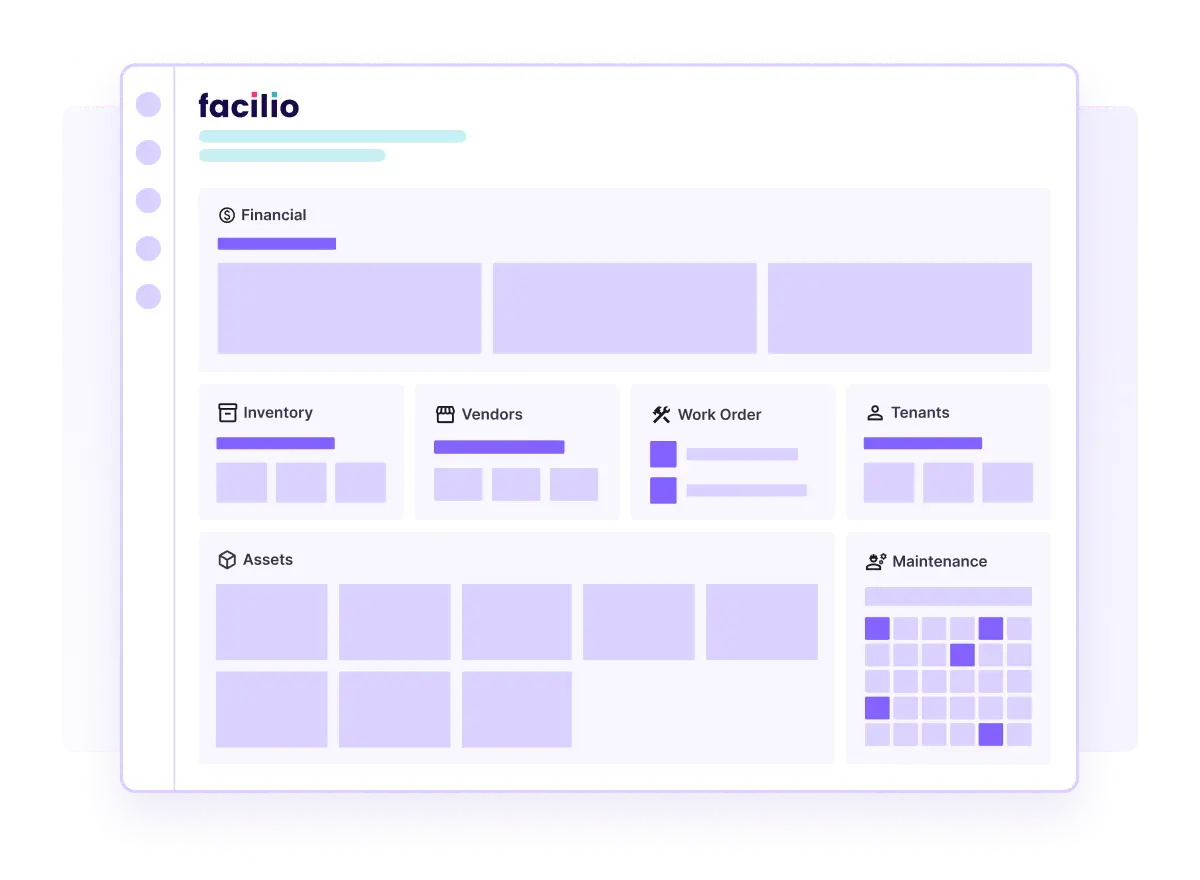

Unlike traditional predictive maintenance software, Facilio consolidates all aspects of facility operations, like vendor management, workflow automation, and stakeholder engagement, into one adaptable platform. Facilio is built with low-code configuration and IoT-based interoperability, making it easy to configure and implement.

Key features

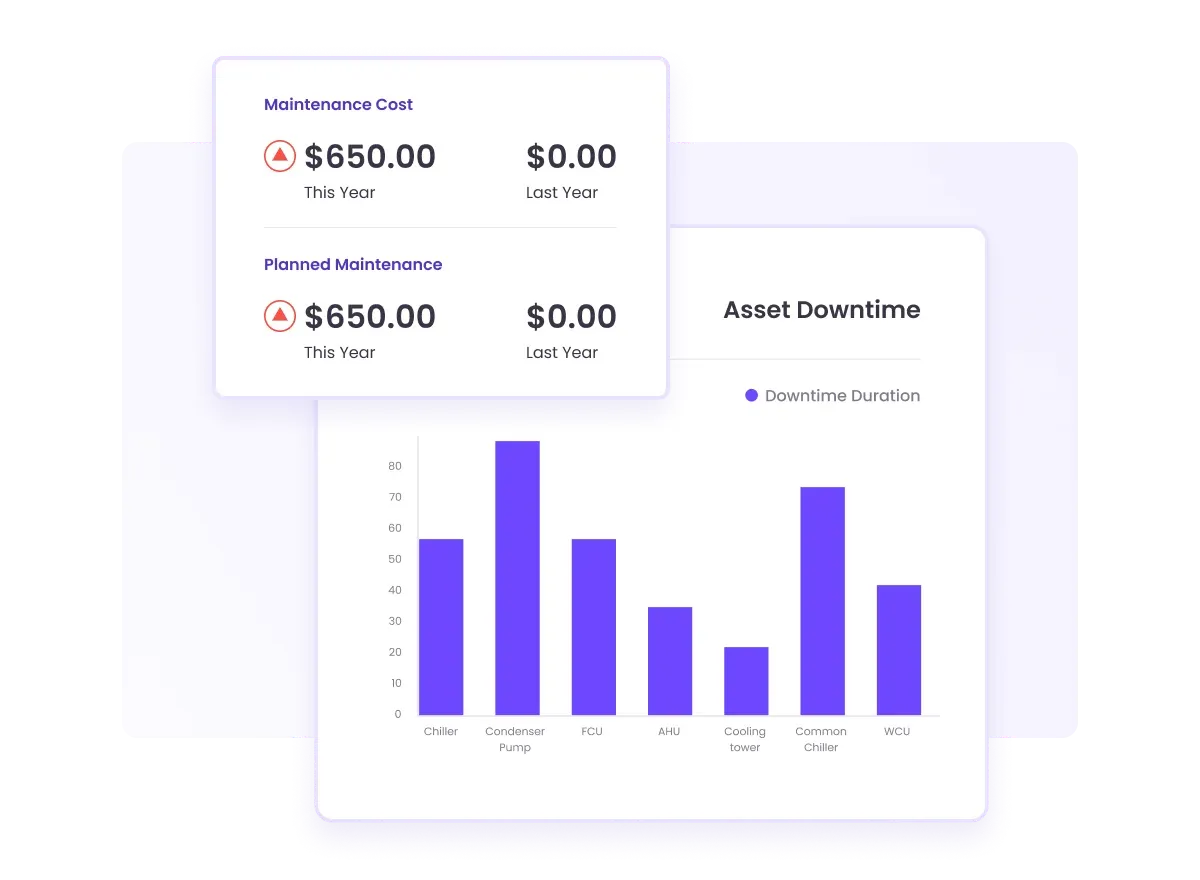

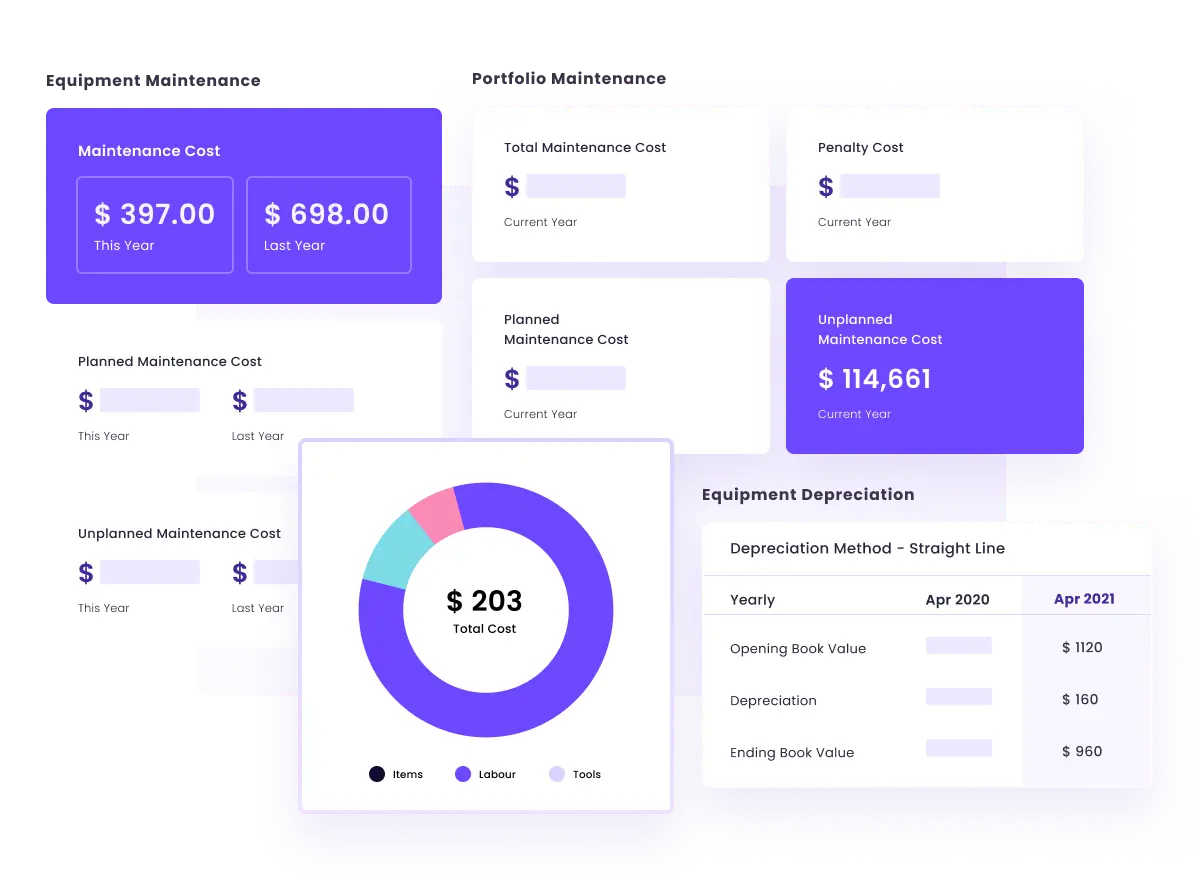

- Predictive maintenance: Facilio offers a comprehensive maintenance management suite. You get visibility into your maintenance operations via metrics like mean time to repair or replace, extra cost, lifecycle cost, and downtime/uptime. You also get a unified maintenance platform for planning, scheduling, and executing maintenance-related tasks.

- Work order management: The platform streamlines work order management with tailored workflows. Your vendors and in-house employees get to access it via intuitive mobile apps and web portals. You also get to create custom workflows using plug-and-play templates, which require no coding knowledge. The calendar-based dispatch tool is designed to optimize resource scheduling.

- Inventory management: Facilio offers standardized inventory processes, allowing your technicians to issue requests for additional parts, which can then be promptly processed by store managers. The reporting dashboard offers visualizations of parts usage patterns, tracks inventory levels, and forecasts purchases. These insights help you make data-driven budget decisions, reduce overhead costs, and improve overall oversight.

- Integrations: Facilio has over 50 integrations with building automation and business apps, including Google Apps, Slack, WhatsApp, Netix, Trane, and Honeywell.

- Energy optimization: Facilio’s utility management features use meter data to analyze real-time utility consumption trends and identify high-energy-consuming assets. Use this information to take proactive measures to minimize waste and optimize energy usage across your portfolio. Learn more on Energy Management Software

- Digital inspections: Facilio offers on-the-go digital checklists, ensuring accuracy and transparency. Use the pre-built templates to standardize the process, automate schedules for reliable checks, and achieve audit readiness.

- Highly comprehensive workplace management: Facilio lets you visualize all facets of your facility management in one feed—tracking expenses, active work orders, assets, and energy with zone-and-site-level details. Enhance your experience with segmented visitor management profiles and automated safety protocols, ensuring a secure and comfortable environment for all tenants.

Pros & Cons

- Diagrammatic data that is easy to understand and analyze

- User-friendly interface

- Excellent customer service and support

- Some think the graphics and background can be improved (GetApp)

Rating - 4.0 ⭐️⭐️⭐️⭐(Based on Capterra reviews )

See why top CRE leaders are betting their future on data-driven O&M, Check out

2. Fiix CMMS

Fiix by Rockwell Automation provides asset management, analytics, reporting, and mobile maintenance, all backed by powerful AI technology.

Fiix’s predictive maintenance solution has a wide range of use cases for industries such as oil and gas, heavy equipment, food and beverage, and manufacturing.

Key features

- Asset risk predictor that uses AI to predict and prevent failures

- Work order management

- Inventory and maintenance management

- Asset tracking

- Work order creation

Pros

- Uses AI to predict equipment failure

- Is well-suited for smaller companies with limited inventory items

Cons (Capterra)

- Inability to make bulk edits

- Difficulty in navigating user permissions

- Challenging implementation

3. eMaint CMMS

With over 50,000 users worldwide, eMaint CMMS focuses on managing work orders, parts inventory, and predictive maintenance schedules.

Key features

- Preventative maintenance

- Work order management—automatic triggers, drag and drop calendar, offline app to keep the entire team connected

- Asset management

- Analytics and reporting

- Regulatory compliance—eMaint supports organizations in achieving compliance with OSHA, EPA, GMP, FDA, EudraLex, and ISO standards

Pros

- Flexible and configurable interface

- Easy work order creation and processing that’s accessible to both managers and technicians

- Over 1000 integrations and API access

Cons (G2)

- Limited options for customizing reports

- Lack of mobility and communication within eMaint

- Lacks wireless hour meter feature

4. IBM Maximo

IBM’s Maximo Application Suite provides predictive maintenance analytics. It uses data from IoT sensors and Enterprise Asset Management (EAM) systems to improve asset reliability.

Key features

- Physical asset management

- IT asset management

- Predictive maintenance, which includes five popular predictive model templates and associated visualization

- Reliability-centered maintenance

- Remote monitoring

Pros

- Extensive asset tracking that covers a wide range of asset types

- Industry-specific solutions

- IBM Watson Machine Learning technology

- AI-infused analytics

Cons (G2)

- Complicated search function

- Initial setup and configuration is complex and time-consuming, requiring technical expertise

5. Fracttal One

Fracttal One is a user-friendly maintenance management software that provides comprehensive control of maintenance operations, mobility, and interoperability.

Key features:

- Fractal Business Intelligence—customize and understand visually represented data

- AI-driven maintenance operations

- Smart automations

- Detailed work orders

- Asset management

- Maintenance requests—scan QR codes of assets’ NFC tags

Pros

- The predictive maintenance software is accessible over mobile, online web portal, and is cloud-based, providing control over company assets from anywhere

- Wide-range of use cases including maintenance service providers, healthcare facilities, transport, logistics, and hospitality

- Designed for remote workers and is easy-to-use and deploy

Cons (G2)

- Being a web-app, it needs fast internet connection to transfer information to the software

- Users cannot create work orders directly from asset view

6. Upkeep

Upkeep is a cloud-based management maintenance system that maintenance and reliability teams use to simplify, optimize, and organize maintenance operations.

Key features:

- Workflow automation

- Asset management

- Predictive maintenance

- Automated alerts when stock runs low

Pros

- 30+ integrations with third-party software to streamline maintenance and business operations

- Generate compliance reports and get access to historical documents and regulatory manuals

Cons (Capterra)

- The assets are not set up to model the facility’s process flow

- Constant updates alter the interface occasionally

Related Read: Top 10 Best CMMS Software

How to Choose the Best Predictive Maintenance Software in 2024?

Here are nine considerations to keep in mind when you’re choosing a predictive maintenance solution for your business:

- Features: Asset management, analytics, preventative maintenance, and work order management are the four must-haves. If a tool doesn’t offer all four, look elsewhere.

- Ease of use: Many predictive maintenance tools are designed only for technicians. However, look for a solution that can be used by all stakeholders of your organization, regardless of their technical proficiency.

- Scalability: The number of your facilities and assets may change. You want a solution that can be easily scaled up or down according to your needs. Ease of use is a good marker of scalability. If a tool is difficult to use right out of the box, it will get only more complex as you try to scale it up.

- Accuracy: You want a solution that accurately predicts equipment breakdown. After all, that’s what predictive maintenance is all about.

- Cost: Predictive maintenance solutions are charged upfront, monthly, quarterly, or annually. Some also charge extra for implementation and training and any extra features you want to add. Keep these considerations in mind when budgeting and searching for solutions.

- Integrations: Look for a predictive management and maintenance software that integrates with the specific software and business sources you use in day-to-day business operations.

- Equipment type: You want a solution that’s compatible with the type of equipment you own. Whether it’s HVAC systems, manufacturing machinery, or fleet vehicles, determine what you want to monitor and choose software accordingly.

- Data volume: Ask the company rep if their predictive maintenance solution can handle all the data you want to collect without breaking down.

- Cloud-based vs on-premise: While most predictive maintenance software is cloud-based, an on-premise solution might be more suitable for you if you have stringent data security requirements to meet.

- IoT support for all major equipment: Predictive maintenance would not be possible without functioning IoT sensors. You want to look for a solution that offers IoT support for all major equipment at your company.

If you’re not sure where to begin your search, consider Facilio. We offer so much more than asset and maintenance management. You get work order management, digital inspections, multi-store energy optimization, as well as service, vendor, and workplace management features — all without going through a single line of code.

These features have helped our customers reduce asset downtime by 40%, reduce reactive call volumes by 30%, and manage up to 15% cost savings across their buildings.

If you’d like to do the same, book a demo today.

FAQs

1. Which type of industries can utilize predictive maintenance?

Predictive maintenance can be used in a wide range of industries, including commercial real estate, corporate facilities, facility management services, healthcare, retail, and education.

2. Which technology is used in predictive maintenance?

Predictive maintenance uses a variety of technologies including predictive analytics, AI, and IoT.

3. Is predictive maintenance right for your business?

Whether or not predictive maintenance is right for your business depends on its type. If you have expensive equipment to maintain or multiple facilities that need energy optimization, then investing in predictive maintenance is a must.

4. Are predictive maintenance software secure?

Yes, most well-known predictive maintenance tools are secure. For example, one of the main ways Facilio ensures data security is by hosting services on Amazon Web Services (AWS) cloud facilities with stringent security standards.

5. How much does a predictive maintenance system cost?

A predictive maintenance system can cost anywhere between $45 and $126 or more (per user per month), depending on the solution you choose and the pricing plan you go for.